- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- change systems

Results for

Change systems - Import export

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The automatic feeding of tools from the tool magazine to the machining spindle is implemented in modern machining centers with the aid of a tool changer. At the same time, this device is used to return tools to the tool magazine. Reducing non-productive times is an important criterion for increasing the efficiency of machining centers. The chip-to-chip time is directly positively influenced by a fast tool change, i.e. a short tool change time.

Request for a quote

KAMAT GMBH & CO. KG

Germany

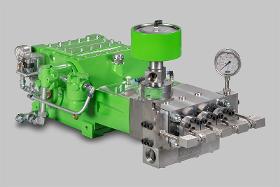

High-Pressure Cleaning, Load Change Systems and Pressure Test Systems If your application requires forced lubrication and an oil cooler may be required, the powerful K9000-3G three-plunger high-pressure pump is an alternative to the smaller K8000-3G three-plunger high-pressure pump. Like the compact K8000 model, this 90 kW high-pressure pump is suitable for smaller industrial applications such as industrial cleaning, jetting or process engineering. SPECIAL FEATURES - Capacities at 100% volumetric efficiency and 20°C ambient temperature - Minimum inlet pressures depending on fluid - Speed range 10-100% depending on rod force - Forced lubrication gearbox (> 75 kW with oil cooler) - Standard gear ratios i = 2.75 - 3.22 - 3.68 - Also available to API 674 - Special fluids such as seawater, glycol, methanol, oils, etc. on request - Vertical operation possible

Request for a quote

FRIMO GROUP GMBH

Germany

Hydraulic presses for a broad variety of pressing, foaming, punching and forming tasks FRIMO HyPress standard machines can be adapted to fit table size, stroke, clearance, and press force requirements. Numerous options are available including safety packages, pivoting rams and tables, tool change systems, automation solutions, and complete customizations. The standard presses are designed as bolted, welded structures. The machine feet, head and sides are manufactured with high precision and fastened with fitting keys. The ram is guided via prisms and can be easily readjusted. It can alternatively be column-guided.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Powder systems with robots can be effectively used even for small batches. In addition to the classic method of powder coating using manual spray guns or masts, the demand for robot systems has risen sharply. Rippert offers the entire spectrum here too. Both powder-coating systems with robots and wet painting systems are supplied with intelligent software solutions. This also allows the economical processing of small lot sizes. Automatable high-speed paint changing systems have also been available for some time. Rippert plays a leading role in automated powder-coating systems with industrial robots.

Request for a quote

ABS SAFETY GMBH

Germany

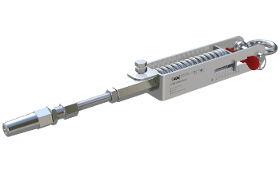

This stainless steel lifeline end attachment - specially designed for our ABS-Lock SYS (8 and 6 mm) lifeline systems - can be used to compensate deviations in temperature. This tensioning element is made of 316 steel, is equipped with a spring bias and has been awarded national technical approval by the German Institute for Construction Technology (DIBt). General national technical approval (German: "abZ"): Z-14.9-786 EN 795:2012, C & CEN/TS 16415:2013 Spring bias with an easily-readable gauge Inspection window allows monitoring of the cable clamping mechanism Counters slack caused by temperature changes One-piece clamping system Easily installed Manufactured completely from robust V4A stainless steel

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

The large volume booth used here enables an increase in the flexibility and, at the same time, a higher production and quality assurance than that used in the VEN SPRAY MIN concept. Integrated fast colour change systems for one and two component lacquer systems as well as the feasibility of a wet in wet application of two lacquer systems (depending on the paint systems) in one pass, establish faster production times, reduced rejects as well as a resource saving utilization of the spray media. Example of a complete finishing line including pre-treatment and drying:

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

This "stand-alone solution" is designed to meet flexible production requirements and can be used for solvent and water based paints. This spray coating machine is both economical and environmentally friendly. It can optionally be equipped with a belt cleaning system and/or a paper transport belt.This makes it possible to alternate between both modes of operation. A quick change between two paint systems (water/solvent based) is simple and fast. This makes it especially attractive for smaller companies to replace manual painting. Working width: 1,300 mm, Working height: 920-960 mm, Machine dimension: 1,900 mm (length) Feed speed: 2-4 m /min. Exhaust air volume: 7,000 m³/h, Supply voltage: 9.6 kW/ 12 A,

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

With its VEN SPRAY PERFECT Venjakob has the innovative answer to all requirements encountered on the market. Based on decades of know-how in the realisation of high-performance spray painting plants, it is the flexibility of this new generation that convinces. In the long term, the modular system takes into account all production requirements. At the time of machine purchase, its concept realises all variants, from "one off batch size" through to large series production in the high-end range. The modular concept permits implementation of changing framework conditions at any point in time by retrofitting new modules, thereby making your investment future-proof. Working width: 1,300 / 1,600 / 2,200 mm Working height: 940 mm Feed speed: 3-8 m/min Exhaust air volume: 7,000 - 10,000 m³/h Connection value: 20 KW Machine dimensions: 2,280 / 2,800 mm (length of booth) The sophisticated spray gun control minimizes the rate of overspray. With the patented V-belt design up to 98 % of the liquid overspray can be reclaimed. The paint retrieved in this way is recycled into the paint process. Over and above, the innovative ventilation system improves the ecological energy balance. The short setup times, long service life of the filter elements, fast changing times for spray systems and automated paint-change procedures offer a very high degree of efficiency. The twin cleaning units allow the use of solvent-based paints as primer and the direct switchover in split seconds to the second cleaner operating with water-based paints. Maintenance and cleaning operations take place completely separate from the production process.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

The BestConnect system is designed to provide rapid assembly of conveyor solutions for changing workplaces. Systems can be easily configured and reconfigured as required to suit your immediate requirements. With a simple 240v power supply and latching connections, the engineering requirement is minimal. Continuous Duty Multiple Drive Motors 20 to 120 Vdc geared motors. Adjustable speed is from 2 to 36 metres per minute. Start/ Stop controls at both ends. Adjustable Height Telescopic legs to raise or lower the conveyor height. Square Tubing Legs Heavyduty square tubing legs offer longer service life and stability. 50mm Roller Heavyduty precision bearing rollers on 12mm axles for greater durability.

Request for a quoteResults for

Change systems - Import exportNumber of results

10 ProductsCompany type