- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- brushing machines

Results for

Brushing machines - Import export

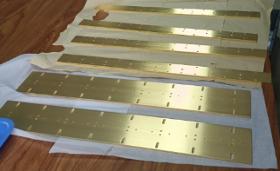

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These accessories were made by copper, after CNC machined, then process brushing ,finally do the gold-plating .

Request for a quote

JETCLEAN GMBH

Germany

The FERRET pipe cleaning machine is a user-friendly and handy tool for cleaning horizontal and vertical flue gas pipes. This eliminates the need for strenuous cleaning with brushes on a rod or awkward fiddling with rotating shafts. This significantly reduces the cleaning time. The FERRET machine is driven pneumatically. The oscillating brush propels the machine forward automatically and ensures an excellent cleaning result. Air consumption is low. A work area of approx. 0.5 m in front of the boiler is more than sufficient. Use the FERRET machine to clean your flue gas pipes up to a residual temperature of 150 °C. The use of special vacuum cleaner nozzles means that work is carried out virtually dust-free.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

To conform to market requirements, widely differing machines for painting/coating mouldings, window parts and other profile components were developed. The type and number of guns depends both on the paint system and on the quality envisaged. Air, Airmix or Airless spraying systems can be used for this purpose. The individual machine types can be configured with all conveyor systems of our portfolio and combined with the respective drying systems. The difference between the VEN SPRAY MOULD (LT) and (LW) variants is their type of extraction. LT stands for dry extraction, LW for water-backed extraction. VEN SPRAY MOULD COOLAC is exclusively designed for processing water-based paints. The overspray is constantly collected and condensed in chilled collector systems. The condensation of the controlled air humidity keeps the collector devices and chilled conveyor systems permanently wet. This reliably prevents paint particles from drying during operation. The strip painting plants can be supplemented by further Venjakob plant technologies specifically tailored to the process such as brush sanding/denibbing machines, dryers or conveying equipment.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

Dust removal devices remove adhering dust particles from the workpieces by means of rotating blowing nozzles. The use of ionisation units enables the removal of electro-static charges from the plastic surface, which promote the adhesion of dust. In order to improve operation, the ionisation unit is combined with a dust removal/blow-off device. In the wood sector, this is generally integrated in the line without ionisation unit or installed directly downstream of a brush sanding/denibbing machine. We offer various dust removal/ionisation systems, according to the requirements of your production process. The COMFORT and PERFECT versions are additionally equipped with a rotating genuine hair brush to remove soiling from the surface. We would be please to provide more detailed information concerning the equipment features upon request.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Brushing machines - Import exportNumber of results

4 ProductsCompany type