- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- belt

Results for

Belt - Import export

JUMBO-TEXTIL GMBH & CO. KG

Germany

Item No.: 6917-15 Belt Specification Woven belt Model type: S (Standard) Dimensions: approx. 30.0 mm wide Material: Spun rayon Colour: skin tone Property: non-elastic Packaging: rolled with core

Request for a quote

JUMBO-TEXTIL GMBH & CO. KG

Germany

Item No.: 485604 Belt Specification Woven belt Model type: C (Customised) Dimensions: approx. 40.0 mm wide Material: Acrylic Colour: olive/brown/olive Property: non-elastic Packaging: rolled

Request for a quote

LESJÖFORS INDUSTRIAL SPRINGS & PRESSINGS GMBH

Germany

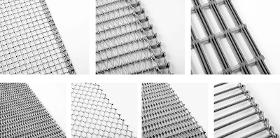

The Dutch Lesjöfors company Tribelt specializes in developing and manufacturing metal conveyor belts. For more than 70 years, the company has solved problems for customers in many different fields across Europe. We also manufacture sprockets, customized for the design and in the number your application require, its’ tension forces and surrounding environment.

Request for a quote

F.E.S. GMBH

Germany

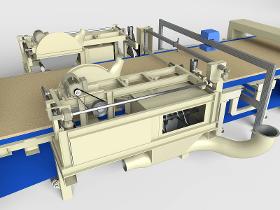

Pressure belt filters are used for cleaning contaminated cutting fluids in metal processing and rolling mill applications. Cleaned cutting fluids have longer lifespan, improve surface quality, and contribute to heat dissipation at the processing or forming point. Advantages: High throughput capacity No backwashing during regeneration Easy discharge of filter cake Short regeneration time Compatible with various plastic filter belts High and low-pressure rinsing system Affordable price Operation: The F.E.S. pressure belt filter addresses the need for filtration without disposal issues by utilizing a standard feature of a circulating plastic filter belt. A filter belt cleaning device is integrated into the head section of the belt filter. The closing mechanism of the sealing flaps, lowered pneumatic cylinders, and movable protective covers ensure a low height for easy installation and operation.

Request for a quote

F.E.S. GMBH

Germany

Hinged belt filters, also known as folding belt filters, are used for cleaning contaminated coolant fluids in metal processing and rolling mill applications. Cleaned coolant fluids have longer service life, improve the surface quality of workpieces or rolled goods, and assist in heat dissipation at the processing or forming site. Advantages: High throughput capacity No backflushing required during regeneration Easy discharge of filter cake Short regeneration time Compatible with various plastic filter belts High and low-pressure flushing system Cost-effective Operation: The F.E.S. hinged belt filter incorporates a circulating plastic filter belt to meet the filtration requirements without disposal issues. A filter belt cleaning device is located below the filtrate discharge chamber. The opening and closing of the chambers are controlled by two pneumatic cylinders. The self-locking toggle lever mechanism keeps the chambers closed even in the event of a loss of compressed air.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The mat trimming saw cuts the precompressed mat precisely to the width required. Two motor-adjustable saws, one each on either side of the belt, cut the bre mat to the dened width. The trimming waste is disintegrated and may be recycled to the production process. Features, function Modular design Motor-adjusted saw blades incl. distance measurement Max. trimming waste of 420 mm on either side Max. mat height ex prepress 360 mm Integrated hogger including extraction stub to remove the trimming waste Extraction stub at the saw blade

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The trimming saw is installed downstream of the last surface-layer mat former, cutting the strand mat precisely to the required width. Two motor-adjustable saws, one each located on either side of the belt, cut the strand mat to the dened width. The trimming waste is discharged through a hopper and recycled to the mat former bins. Features Motor-adjusted saw blades incl. distance measurement Movable mat edge retainers to ensure high-quality cuts Lateral pressure rollers ex saw compact and smoothen the mat edge Movable extraction system adjustable to mat thickness Advantages Recipe-related adjustment of all adjustable axes Eective strand extraction

Request for a quote

IGUS® GMBH

Germany

drylin® ZLW-0630 basic toothed belt axis, basic version, feed rate 54mm/rev, aluminium profile, surface: hard-anodised, neoprene toothed belt in black, guide carriage length 60mm, shaft end support made of aluminium, alignment of drive pin on the right, stepper motor with stranded wire. Configure drylin SHT linear modules individually here: https://igus.eu/ddx

Request for a quote

LAWECO MASCHINEN- UND APPARATEBAU GMBH

Germany

The latest development in lifting platform technology is based on mechanical drive technology using belts. Hydraulic oil is not required. Due to a patented catch system, BELT-LINE meets the safety requirements laid down in DIN EN 1570. The combination of exemplary positioning accuracy, smooth running and long service life is the reason the BELT-LINE is an economical precision solution, and not only for sensitive areas. Exemplary smooth running BELT-LINE convinces with a low noise and harmonious movement sequence, paired with maximum lifting speed and positioning precision. Minimum maintenance time and costs without hydraulic oil In particular in sensitive areas, the robust BELT-LINE technology with its long operating life is the best possible solution. The low-wear components can be quickly replaced due to the modular design. Excellent load change behaviour In the design phase, particular emphasis was placed on developing an excellent load change behaviour. The resilient suspension behaviour is only surpassed by LAWECO push-chain lift platforms.

Request for a quote

FRIEDR. FREEK GMBH

Germany

The HSSD - Side Drum Heater is an easy and actual aid to the warming of steel barrels. It has got a higher efficiency than the Insulated Jacket HISD, but no thermal insulating function. For a very quick heating and higher temperatures up to three drum heaters can be used simultaneously for a 200-liter barrel. The Side Drum Heater is available in four standard sizes (25 / 50 / 105 / 200 liters) and can of course be made to measure, too. HSSD - Side Drum Heaters are suitable in particular to defrost frozen or other products, thus allowing to empty the barrels rapidly. Soaps, fats, varnishes and oily products can be melted as well, respectively reduced in their viscosity. In addition, the 200-liter element can be used in conjunction with the HBD Base Drum Heater to shorten the heating-up time further.

Request for a quote

GSW SCHWABE AG

Germany

the conveyor system TB2000 distinguishes itself through its compact design. A modular scaling allows quick delivery while serving a great variety of applications. large belt widths and higher capacities allow removal of scrap also with bigger presses. the nuts on the sides can be used problemfree for tightening the directional controls or other accessories

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

We offer a wide variety of grades with various dimensions and grain sizes of abrasive belts that are perfectly suited to your application and processes. We will be happy to advise you to find the right sanding belts for you.

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Scope of delivery: 1x ball unit table 6x freely positionalable stop bar – long 4x freely positionalable stop bar – short 1x set of bolts anti-tilting Load capacity for tools, dies, injection moulding tools, assembly goods etc. up to: 500 kg – higher loads possible with ball units 022.100 Purposes Setup and dismantling, internal transport, flexible work table e.g. in toolmaking, can be used for forklift trucks, pallet trucks or pallet jacks Advantages Reduced set-up time, safe, flexible, universally applicable, simple and fast handling Safety at work flexible fall protection for conveyed goods, simple and quick tilt protection, stop bars freely positionable in the grid The SUTTY has a CE mark – Quality, made by Schulz!

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

cam type closure*cork lined jaws*capacity Ø 60 –170 mm*rod Ø 10 mm

Request for a quote![Hinged Edge-protector For Lashing Belts [sk-b]](/filestore/vig280/opt/product/e7/7d/secutex_Edge-Protector-SK-B_001_3e6201ae.jpg)

SPANSET SECUTEX GMBH

Germany

By means of a hinge, the edge protector SKB can be optimally suited to fit any load geometry. It can be optionally equipped with magnets to better retain its position on the magnetic load. The edge protector can be quickly secured to the edge of the lashing belt by means of mounting slits. The lashing belt slides through the secutex clip which remains on the lashing belt despite collisions. Optionally available Magnets for easy fixation of the magnetic load

Request for a quote![Simple Edge-protector For Lashing Belts [sk-be]](/filestore/vig280/opt/product/67/d5/secutex_Edge-Protector-SK-BE_001_9bfa8fb8.jpg)

SPANSET SECUTEX GMBH

Germany

Even when securing the load, the lashing material must be protected against the „sharp edge“. Highvalue loads may not be damaged by lashing chains or ropes. The SKBE secutex simple edge protector has a low deadweight and is easy to handle thanks to the flexible textile reinforcement. It is simply pushed onto the lashing material via the fulllength opening on the reverse side and is thereby impossible to lose. Important note the secutex simple edge protector SKBE is not suitable for prolonged use.

Request for a quote

GSW SCHWABE AG

Germany

the conveyor system TB1000 is suitable especially for the integration into complex machines (e.g. removal of scrap from punching machines) because of its compact design the aluminum extrusion framework resists twisting and at the same time features good load capacities under the running surface of the belt, a stainless steel plate is mounted to secure an enduring resistance to abrasion

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Stable dust-tight design for harsh industrial conditions — Removable doors for quick cleaning — Usable as a continuous or batch-wise metering belt feeder or for throughput metering (operating mode can be changed on the controller) Power range 200-50000 dm³/h

Request for a quote

ROLKO KOHLGRÜBER GMBH

Germany

In our range of belts you will find pelvic belts, harness belts, leg belts, thigh belts, shin belts, calf belts, heel belts and foot belts in various designs and sizes. All straps are specially designed for wheelchairs, children's wheelchairs and other rehabilitation equipment and with attachments suitable for them. In addition to our standard range, we also manufacture customised belts or adapt our existing products with our many years of know-how in the industry, not only according to the wishes of our customers, but also according to the latest European norms and quality standards. Do you have any questions about our products or would you like to request a quotation? Just contact us. We have the right belt for almost every application!

Request for a quote

KB ROLLER TECH KOPIERWALZEN GMBH

Germany

The latest generation of color laser printers have four toning stations (CMYK). Paper passes all four stations in one cycle which enables higher print speeds. This design requires precise positioning of the belt with respect to the paper during the toning cycle. This need defines the properties of a seamless belt for a perfect printout: Perfect, defect-free surface Tight tolerances of diameter, length, width and surface roughness Precisely defined electrical conductivity over the entire belt surface KB RollerTech`s capabilities: Diameters: up to 1,000 mm Width: up to 600 mm Thickness: 50 - 100 µm (±10%) Electrical properties: 1E5 - 1E16 Ohm cm Roughness: < 1,0 Ra Primary and Transfer Charge Rollers Charge rollers are critical for long lasting, high quality printouts in laser printers and copiers. KB Roller Tech’s special compounds enable charge rollers to maintain continuously stable electrical properties. Primary charge rollers are mostly soft coated rollers with sensitive surf

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

It is of vital importance that the oriented mat be conveyed precisely from the forming line into the infeed head of the ContiRoll®. Otherwise a dependable production process and a symmetrical heating of both surfaces could not be guaranteed. We therefore use an intermediate belt, which is perfectly tuned to the exible infeed head of Siempelkamp’s ContiRoll® and which adjusts automatically to the respective recipe and process Parameters. Features Basic frame including belt drive Belt tracking unit Tensioning device Motorised slide table, swivelling and moving in production direction Pulley unit Advantages Preassembled unit, modular design integrated in the forming line Positioning of the slide table in the press infeed in dependence on the recipe Options Belt cleaning brush Seamless, endless belt

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

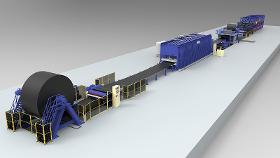

One of Siempelkamp’s core competences is the design and manufacture of presses for the rubber industry. With our expertise in this eld we are the world’s number one in steel-cord and conveyor-belt presses with many of the conveyor belts used around the world being manufactured on our equipment. Despite heavy loads, these conveyor belts always have to have best straightrunning stability. Siempelkamp's excellent manufacturing and high-quality plants are eld proven. Services Single-source supplier Uniform pre-tensioning of the individual steel cables Best pressure distribution in our vulcanising presses Cable clamping and tensioning device with a heavy clamp Compactor lorry with pre-press Pull-roll stand Reeling elements Advantages Excellent thickness tolerances due to multi-cylinder press without requiring press bolsters Safe vulcanizing process for various belt widths by controllable pressure distribution Transparent and controllable production process

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

Continuous blasting – Excellent, highly automated processing The selected blasting medium is directed towards your workpieces at high speed using blast wheels. This ensures high blasting performance and optimum use of energy. Using this technology in a continuous process offers several advantages over batch processing: — Continuous workpiece feeding — Easy to integrate into production processes — Simplified parts flow That is why our continuous belt blasting units are frequently used to replace conventional batch systems. With their easy workpiece handling and excellent blasting results, they are even used as replacements for suspended-line systems.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

The use of wide belt, grid, steel band or narrow belt conveyors is adapted to the type of workpieces as well as to the customer-specific conditions. They can be flexibly planned either as an individual solution or incorporated in a Venjakob machine line. A wide spectrum of belt types is available, matched to the individual fields of application. This even includes applications up to a maximum temperature of 450°C. VEN TRANS system techniques enable tailor-made workpiece conveying and handling concepts. We create Our solutions take into account

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

Whether straight, inclining or declining – the Motion06 Belt Conveyor transports luggage, packages and general cargo across any distance. As a modular system, the conveyor belt is suitable for a wide variety of requirements. The basic model includes the head drive or central drive, reversing station, normal round, pass round and support or suspension modules. The transitions between the individual conveyors are fitted with individual transition sheets. The tensioning station at the head drives and reversing stations is tensioned from both sides on the basic model. The tensioning station on the centre drives is tensioned on one side. SBC – 080/112/157. Structural Lengths Short structural lengths of approx. 600 mm conveyor length and, for example, belt width of 1.000 mm possible. Any Height Requirements Low overall height possible with integrated belt tracking device. Floormounted version or suspension from the ceiling incl. individually adjustable height and angle are also available.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

With a conveying speed of up to 3.0 m/s, flexibility and hardiness are also demanded of the curves. The area of application for the Motion06 Curved Belt Conveyor is in the continuous or clocked transportation of pieces of luggage and packages with changes in direction. When developing the Curved Belt Conveyor, the highest priority was given to the ‘small space requirements’ and a wide range of standard measurements or customerspecific measurements for integration into new or existing systems. The entire product range is a modular design and is designed based on stateoftheart technology. A consistent appearance for the operation of a wide variety of weight classes and product sizes is available worldwide. Structural Lengths Short structural lengths of approx. 600 mm conveyor length and, for example, belt width of 1.000 mm possible.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

The Motion06 Hand Baggage Control Unit conforms to the latest standard of technology and requires minimal staff involvement for handling. The defined field of use is automated hand baggage transportation into containers with automatic container return. This keeps the manual handling of the containers to a minimum. The security personnel can focus entirely on checking passengers and baggage. UltraSimple Adjustments Ultrasimple adjustment to required installation conditions with modular system Universal Compatibility Can be combined with all conventional XRay machines. No Maintenance Maintenancefree lifting system thanks to lifetime lubricated bearings and optional toothbelt drive. Quick Installation Swift assembly due to a simple modular system, perfectly optimised for transportation.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

A real highperformance device – ingenious, innovative and extraordinary. Its job is to sort out pieces of baggage or general cargo from a conveyer line with the highest possible sorting output. Its capacity is up to 1,500 pieces of baggage per hour. The Motion06 High Speed Diverter is output to the power of two. The currently common and expensive twoband diverters can now be replaced economically. Thanks to the latest drive concepts (Class IE4), the High Speed Diverter is extremely energy efficient and the flexible construction concept makes changing the swivel direction on site simple. Maintenance free components with the lowest possible operating costs are included. Due to the standalone principle, the machine is easy to integrate without mechanical connection to the feed system (to the lower conveyor belt of the line).

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

From 0 to 3.0 metres per second. The Motion06 Strip Belt Merge puts baggage on the right track like no other. It is exactly this construction – the design as an adjoining merge point – that can provide the fundamental advantage of operational safety. In the case of one strip being damaged, the system continues to work flawlessly. In connection with a belt deflector, the merge can also be used to transfer baggage from different angles. Simple Installation Ultrasimple adjustments for required installation conditions. Various Designs Horizontal or sloping design. Conveyor Casing Casing can be steelcoated or stainless steel. Low Maintenance Lowmaintenance friction drive Quick Installation Swift assembly due to a simple modular system, perfectly optimised for transportation.

Request for a quoteResults for

Belt - Import exportNumber of results

62 ProductsCompany type

Category

- Conveyor belts (34)

- Conveyor systems (13)

- Transmission belts (4)

- Wood veneer - machinery and equipment (3)

- Industrial equipment hire (2)

- Machine tools, metal shaping - parts and accessories (2)

- Straps, woven - industrial (2)

- Filtering equipment and supplies (1)

- Apparatus and equipment for the disabled (1)

- Clamp collars, plastic (1)

- Electroheat - machines and equipment (1)

- Forming, rubber - machinery (1)

- Grinding - steels and metals (1)

- Houseware, steel (1)

- Import-export - steels and metals (1)

- Oiling - machines and systems (1)