- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- belt system

Results for

Belt system - Import export

ROLLON GMBH

Germany

Telescopic actuator with a synchronized toothed belt system for effective linear movement and minimal overall dimensions. The compactness of the closed system makes it ideal for environments without much space between the machine and the ceiling. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

ROLLON GMBH

Germany

Telescopic actuator with a synchronized toothed belt system for effective linear movement and minimal overall dimensions. The wall-mounted system feeds the machine and retracts, facilitating the feeding of machine tools where obstructions to protective doors must be avoided. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

ROLLON GMBH

Germany

Versatile transfer system for metal sheet handling, designed as the main element in a series of presses which eventually combine with load/unload systems. The system features high positioning precision with heavy duty cycles and high dynamics, and is also available for very extended lengths. It manages cantilever loads to keep one side of the series free for operations. The system is driven by a belt with Ω transmission. The Z axes can be placed at different distances, according to the loads. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

ROLLON GMBH

Germany

Modline linear modules are toothed belt or ball screw driven systems with high accuracy, speeds and load performances. Our experience in the fields of the automotive plants, painting, plate working, manufacturing machines and palletization systems has allowed us to widen our product range with the most advanced technical solutions. Our products stand out for their: high quality and competitive performances; up to 12-m beams (longer lengths can be obtained with jointed versions), high level torsional rigidity, precise shape; no play transmissions achieved by high torque couplings; beams with transversal stiffening ribs and preset for threads on profile ends; accurate scaling and consequent reduced maintenance; fast and accurate belt or without play screw drives; the most complete range of accessories. The Modline linear module strong points are: toothed belt or ball screw driven linear modules; rolling on trapezoidal or recirculating ball guides; payloads from 3 to 2000 Kg; up to...

Request for a quote

ROLLON GMBH

Germany

Telescopic actuator with a synchronized toothed belt system for effective linear movement and minimal overall dimensions. Horizontally mounted, it is mainly used to feed presses installed in series. It extends in both directions, feeding a press in one direction, closing, then feeding another in the other direction. The closed actuator does not occupy space in the two presses, making it possible to feed both with a single system. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

ROLLON GMBH

Germany

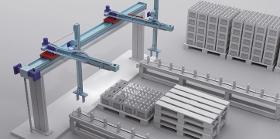

Versatile multi-axis system designed for feeding machine stations. The Y axis can be realized with a rack and pinion driving system for multiple independent carriages or with a short belt system for connected Z axes. The motion systems can be designed with recirculating ball guides or with bearings depending on loads, dynamics, and different environments. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

ROLLON GMBH

Germany

Multiple X/Y/Z Cartesian systems with belt, rack and pinion, screw, and hybrid handling. Utilizing the modularity offered by the full range of our linear actuators (Actuator Line), highly customizable Cartesian systems are available to meet the specific needs of our customers. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

ROLLON GMBH

Germany

Uniline System is a family of pre-assembled linear units boasting a compact size and high speed ensured by the COMPACT RAIL roller bearings, mounted on a self-sustaining extruded aluminum profile. The linear units are driven by a steel reinforced polyurethane belt system. The horizontal seals and the raceway cleaners fitted on both ends of the carriage ensure full protection from dirt. The linear actuator profile is compatible with an endless number of widely available standard fixing accessories. The motor can be connected to the units by means of a full or a hollow shaft Up to 3,000mm strokes Sizes from 40 x 51.5mm up to 100 x 122.5mm Versions available with long sliders and multiple sliders Using linear rails from the COMPACT RAIL family ensures excellent performance in terms of speed and life. The rails in the linear axes of the four product series are laid out in different combinations to meet all application requirements. Using long or multiple sliders increases the...

Request for a quote

LAWECO MASCHINEN- UND APPARATEBAU GMBH

Germany

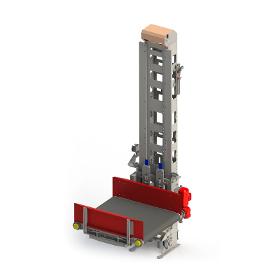

The latest development in lifting platform technology is based on mechanical drive technology using belts. Hydraulic oil is not required. Due to a patented catch system, BELT-LINE meets the safety requirements laid down in DIN EN 1570. The combination of exemplary positioning accuracy, smooth running and long service life is the reason the BELT-LINE is an economical precision solution, and not only for sensitive areas. Exemplary smooth running BELT-LINE convinces with a low noise and harmonious movement sequence, paired with maximum lifting speed and positioning precision. Minimum maintenance time and costs without hydraulic oil In particular in sensitive areas, the robust BELT-LINE technology with its long operating life is the best possible solution. The low-wear components can be quickly replaced due to the modular design. Excellent load change behaviour In the design phase, particular emphasis was placed on developing an excellent load change behaviour. The resilient suspension behaviour is only surpassed by LAWECO push-chain lift platforms.

Request for a quote

GSW SCHWABE AG

Germany

For widths from 200 to 500 mm Pass line height 850 to 1,200 mm the base systems can be simply married with the tslots of the belt body the Base System 51.2 is mounted on one side only and supports widths of up to 150 mm; due to its very large floor plate, one base is usually enough the Base System 53.1 is mounted left and right of the belt body and thus suitable for wide units; since the mounting feet are relatively small, two bases are recommended

Request for a quote

F.E.S. GMBH

Germany

BK 0.5 US/K – BK 2.5 US/K (0.5 – 2.5 m² filter area) Dry cake discharge No fleece consumption compact systems are used for cleaning contaminated cutting fluids in metal processing and rolling mill operations. Cleaned cutting fluids have longer lifespan, improve the surface quality of workpieces or rolled goods, and help dissipate heat at the processing or forming location. Advantages: Fully automatic operation Excellent filtration results without fleece consumption Minimal carryover of cutting fluid Dry cake discharge Low maintenance requirements Full-flow filtration Maximum lifespan of cutting fluid Option for emergency operation with fiber fleece The cleaned cutting fluid is supplied to the system pump (A) from the clean tank (B) of the processing machine (C). The contaminated cutting fluid is introduced into the dirt tank (E) of the folding belt filter system through the lifting stations. The internal processing of the system consists of two steps: “Filtration” and “Regeneration.”

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Excellent board qualities are only achieved when the endless particle mat is degassed and compacted before being transferred to the ContiRoll®. This is realised by the Siempelkamp prepress for particleboard production. Features, function An air evacuation zone, the angles and levels of which are adjustable. High-pressure zone incl. hydraulic position control Two circulating belts Belt cleaning systems incl. extraction system installed along all the belts Advantages Eective prevention of soiling or material jams No belt indents in the board surfaces Variants, options Endless air evacuation belt

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

A homogeneous compaction of the formed mat is indispensable because this is the only way to realise high production speeds and smooth mat transfer to the ContiRoll®. Adequate compaction is provided by the prepress suitable for the production of MDF from 1 to 42 mm. Features, function Two air evacuation zones, the angles and levels of which are adjustable 1.1. zone 1 with a long degassing section incl. a dust extraction system (optional) 1.2. zone 2, medium-pressure zone and degassing via pressure rollers High-pressure zone incl. pressure rollers and hydraulic position control Three circulating belts 1.1. upper air evacuation belt for the degassing zone incl. motorised belt tracking 1.2. perforated press belt (top strand) for the medium- and high pressure zones 1.3. press belt (lower strand) to relieve the circulating forming belt Belt cleaning systems incl

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The drum plastic scraper is for use on light to heavy conveyor belt systems. High quality PU segments for particularly high time of exposure also suitable on spherically rotated drums high flexibility due to PU segments also specially suitable for reversing conveyors belt speeds up to 5 m/s especially for badly damaged belts and PVC belts well suited for use in narrow space conditions limiting damage to the belt longer life expectancy and therefore significant cost savings due to new type of segment shape elastic segments with permanently consistent contact pressure with compression springs (for the automatic regulation of the contact pressure)

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The FTK curved scraper is for use on light to heavy conveyor belt systems. The curved solid carbide bar of Curved standard stripper has particularly in the center of the conveyor belt a high wiping effect and relieves the pressure on the outer edges. belt speeds up to 2 m/s with the mini model. belt speeds from 2 m/s upwards with the reinforced model. specially for use with extremely adhering and abrasive materials and damaged belts and having only a minimal installation height. Areas of use various plants, e.g. for sand, gravel, recycling, compost, clay, brick, asphalt mixing plants and in the gypsum, cement and glass industries etc. Any products adhering to the belt reduce the life expectancy of the conveyor due to the heavy soiling The consequences are usually expensive maintenance measures and production down times. The FTK Förderband Technik Kilian belt conveyor scrapers represent a cost effective development in the field of belt cleaning.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The FTK HM inner belt scraper is for use on light to heavy conveyor belt systems. High tech hard metal enables a particularly high time of exposure. The HM inner belt scraper prevents the material from settling in the inner belt between the belt and the drum and so damaging the drum. Belt speeds of up to 2 m/s with the mini model. Belt speeds from 2 m/s with the reinforced model. specially for use with extremely adhering and abrasive materials and damaged belts and having only a minimal installation height. Areas of use various plants, e.g. for sand, gravel, recycling, compost, clay, brick, asphalt mixing plants and in the gypsum, cement and glass industries etc. Any products adhering to the belt reduce the life expectancy of the conveyor due to the heavy soiling. The consequences are usually expensive maintenance measures and production down times.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The FTK master cleaner scraper is for use on light to heavy conveyor belt systems. belt speeds up to 2 m/s with the mini model. belt speeds from 2 m/s upwards with the reinforced model. specially for use with extremely adhering and abrasive materials and damaged belts and having only a minimal installation height. Areas of use various plants, e.g. for sand, gravel, recycling, compost, clay, brick, asphalt mixing plants and in the gypsum, cement and glass industries etc. Any products adhering to the belt reduce the life expectancy of the conveyor due to the heavy soiling. The consequences are usually expensive maintenance measures and production down times. The FTK Förderband Technik Kilian belt conveyor scrapers represent a cost effective development in the field of belt cleaning. Due to the flexible mounting arrangements and the gentle but thorough cleaning, the FTK Förderband Technik Kilian belt conveyor scrapers lead

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

mechanical belt connectors for use with most PVC, rubber and steel elevator belts, e.g. Supergrip belt connectors Easy to install system with 50 mm segment widths Four versions for up to 1,250 kN/m without limiting belt strength Max. temperature 80ºC, lock nut with nylon insert (standard) Type BC belt connector for steel mesh belts Four versions for up to 2,500 kN/m belt tensile force Maximum stability using high load bolts with self locking nuts Top quality construction in steel and extruded aluminium

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

Whether straight, inclining or declining – the Motion06 Belt Conveyor transports luggage, packages and general cargo across any distance. As a modular system, the conveyor belt is suitable for a wide variety of requirements. The basic model includes the head drive or central drive, reversing station, normal round, pass round and support or suspension modules. The transitions between the individual conveyors are fitted with individual transition sheets. The tensioning station at the head drives and reversing stations is tensioned from both sides on the basic model. The tensioning station on the centre drives is tensioned on one side. SBC – 080/112/157. Structural Lengths Short structural lengths of approx. 600 mm conveyor length and, for example, belt width of 1.000 mm possible. Any Height Requirements Low overall height possible with integrated belt tracking device. Floormounted version or suspension from the ceiling incl. individually adjustable height and angle are also available.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

Conveyor belts are often used to transport bulk materials over long distances, especially in the stone, soil, mining and brown coal industries. Despite good scrapers, material residue often remains on the conveyor belt because of striations and minor damage. The result large amounts of material accumulate beneath the conveyor belt system in the area of the return rollers, and have to be removed by costly cleaning work involving many workers. FTK TURN Operating principle The FTK TURN belt turning station made of highly wear resistant polyurethane turns the conveyor belt through 180 degrees after material transport directly in the reverse direction or into the lower drum. Because of the turning process, the inner, clean side of the belt which never comes into contact with the transported material now has its surface facing down towards the ground. Cleaning is a thing of the past!

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

Pull cords are used as actuators for operating pull rope emergency stop switches along conveyor belt systems. The pull cord and the accessories required for installation are functionally matched to the pull rope emergency stop switch, taking normative requirements into account. We therefore constantly carry out Pull cord, steel cable, 3mm or 5mm red PVC sheathed Various types of tension springs Anchor hook M10 Anchor hook M12 Anchor hook M8 Turnbuckle M6; 2 eyelets Turnbuckle M6; 1 hook / 1 eye Chain link 6 Eye bolt M12x60 * Eye bolt M12x200 * Eye bolt M12x60 * Clamp bracket, size. 3 5 Clamp egg shaped, size. 3 Clamp egg shaped, size. 5 Thimble Gr. 3 Thimble Gr. 5 Marking plate for rip cord Deflection pulley M10x60, pulley And much more

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

Your production spectrum requires both machine technologies? Utilisation, however, is insufficient for a profitable operation of both systems? In this case, make your decision in favour of our new VEN SPRAY CONTOUR! - A 2 in 1 solution. NEW: Belt cleaning system + cleaner and/or combined configuration with a paper belt conveyor system: the paper belt system can be employed for the use of fast drying, non-recoverable paint/lacquer systems (e.g. polyester and 2 C paints/lacquers), whereas the belt system is suitable for recoverable paint/lacquer systems As an option, a selection can be made between dry or wet cleaning. An energy saving recirculating air operation is also possible with solvent based paints (0-50%).

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

FTK side guide rubber is used for particularly fine grained and dusty conveyed goods to seal the material guides of the conveyor belt system. FTK side guide rubber protects the conveyor belt and is mounted along the long sides of the conveyor belt. FTK lateral guide rubber is very flexible and adapts variably to the structures of the conveyor belt surfaces. FTK side guide rubber is available in red 40 45 ° Shore, black 60 65 Shore and in 50 ° Shore.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

FTK Förderband Technik Kilian GmbH products are used all around the world to check conveyor belt systems and bucket elevators for bulk goods. The product range was developed to suit the rugged conditions of the extractive industry, such as the ore mining and iron and steel sectors. That is where reliability and quality count! Ripcord emergency stop switch In the event of an emergency, conveyor belt systems must be able to be switched off at any point along the line. That is why ripcord emergency stop switches are required by standards as additional safety measures. FTK Förderband Technik Kilian GmbH ripcord emergency stop switches have a locking mechanism. They are operated by pulling or breaking the cord. The system is reset manually. “Parts for ripcord systems” are needed to safely install ripcords. These parts are designed to suit our ripcord emergency switches and individual applications.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

For the special requirements of your belt conveyor system, we manufacture for you idler pulleys, carrying idlers, throbbing drums, lift pulleys with or without internally located cone. With diameters up to max. 1,000 mm and lengths up to max. 4,500 mm, these are suitable for all types of belt conveyor system. All pulleys are turned cylindrically or spherically. The axle connections can be delivered in alternative designs with internal bearings, welded, with wedged connections or with clamping set shaft connections. Special designs such as stainless steel and/or friction linings (ceramic, rubber) and accessories (pedestal bearings) can be delivered upon request.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

For the special requirements of your belt conveyor system, we manufacture for you drive pulleys, carrying idlers, throbbing drums, lift pulleys with or without internally located cone. With diameters up to max. 1,000 mm and lengths up to max. 4,500 mm, these are suitable for all types of belt conveyor system. All pulleys are turned cylindrically or spherically. The axle connections can be delivered in alternative designs with internal bearings, welded, with wedged connections or with clamping set shaft connections. Special designs such as stainless steel and/or friction linings (ceramic, rubber) and accessories (pedestal bearings) can be delivered upon request.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

This machine has a twin cleaning unit, therefore it can be used for a dual application of water and solvent based paint systems. Reproducible results guarantee process reliability. The modular construction enables future expansion of the machine line and thereby ensures your investment for the future. Working width: 1,300 mm Working height: 920-960 mm Feeding speed: 3-8 m/min. Exhaust air volume: 7,000 - 10,000 m³/h Connect value: 20 KW Machine dimensions: 5,100 x 3,440 x 2,850 mm (L/M/H) The twin cleaning units of this flexible system technology enable a dual application for water and solvent based paint systems. The targeted paint-recovery by means of the patented V-belt system offers a maximum of profitability and environmental friendliness.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The implementation of impact absorber stations provides effective protection against damage to the conveyor belt in the loading area. The belt is often pierced by sharp, large and bulky goods. Specially manufactured stations supporting impact bars absorb the impact speed. Repair and maintenance costs are thus reduced. In addition, the life expectancy of the conveyor belt and conveyor system is extended as well as the operating conditions significantly improved. Further advantages no jammed rollers causing belt misalignment absorb the drop energy, support the conveyor belt instead of the conveyor rollers in the transport area of the conveyor system and make a reliable running of the belt possible whilst ensuring the least possible friction. infinitely variable alignment to the angle of inclination by means of spindle displacement possible better material sealing due to adjustment of the material guide to within a millimetre

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

Overcome heights, safely and precisely. With its precise and efficient lifting unit, the Vertical Transporting Unit performs a real show of strength – with ease! The belt conveyor element incorporated into the baggage lifter is raised and lowered precisely using a lifting unit with two steelreinforced tooth belts. This maintenancefree lifting system has been tried and tested for decades. Between the two upper and lower end positions, any intermediate destinations can be reached. It is also possible to use the Vertical Sorting Unit in flight baggage systems with a container system. An appropriate Motion06 or FMH conveyor can be incorporated to work with the lifter. VTU – 420/660 Low Starting Height Low overall starting height possible. Any Height Requirements Ultrasimple adjustment for the required input and output positions. No Maintenance Maintenancefree lifting system thanks to lifetime lubricated bearings and optional toothbelt drive.

Request for a quoteResults for

Belt system - Import exportNumber of results

34 ProductsCompany type