- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- air cleaning

Results for

Air cleaning - Import export

TROTEC GMBH

Germany

Just as innovative as the design of the AirgoClean® 140 E/145 E is its intelligent air purification system for permanent control and improvement of the room air quality. Protect your health and the health of the people around you with HEPA-filtered air that is 99.97 % free from harmful suspended particles. The AirgoClean® 140 E/145 E removes pathogenic viruses such as SARS-CoV-2 or the influenza virus, bacteria, fine dust, house dust, pollen, dust mite residues, mould spores or allergens from the room air just as reliably as cigarette smoke, smog and other unpleasant odours. Fully automatically, thanks to state-of-the-art air quality sensors. The air quality sensors of the AirgoClean® 140 E/145 E continuously monitor the room temperature and humidity as well as the air quality and microparticle load of the room air in order to clean it with an intelligently controlled air cleaning performance.

Request for a quote

TROTEC GMBH

Germany

AIR CLEANER TAC 750 EExtremely mobile and variably applicable lightweight – agreeably small in terms of costs and dimensions Air purification made easy! Whether for rebuilds, renovations or restorations – wherever there is construction work in progress the air is quickly contaminated with dust pollutants, endangering the health of employees or residents and polluting adjacent areas. Here, the lightweight TAC 750 E constitutes the perfect solution for air cleaning in smaller construction zones and air pollution control in the surrounding facilities – due to its compact dimensions it also conveniently fits into even the smallest trunk. Developed specifically as vacuum generator for dust‑laden rooms, the TAC 750 E with its effective two‑stage filter system ensures reliable HEPA filtration of the contaminated room air to protect against health hazards and dirt!

Request for a quote

TROTEC GMBH

Germany

EFFECTIVE VIRUS AIR PURIFICATION: MODEL VARIANTS AND SPECIAL SOLUTIONSProfessional Trotec solutions for virus filtration and air pollution control No other method than the HEPA high-performance filter technology provides "as much clean air for quickly diluting the aerosol clouds" with increased safety for the optimum price/clean air ratio! To ensure that you're always provided with the precisely-tailored Trotec solution for effective virus filtration of the room air, exactly adapted to your individual safety requirement, in addition to the high-performance air purifier TAC V+ our range of products contains further model variants and special solutions. To help you integrate the TAC V+ into the respective application environment, in addition to the standard colour yellow, this device is also available painted in the colours basalt grey, white or bronze.

Request for a quote

TROTEC GMBH

Germany

Just as innovative as the design of the AirgoClean® 140 E/145 E is its intelligent air purification system for permanent control and improvement of the room air quality. Protect your health and the health of the people around you with HEPA-filtered air that is 99.97 % free from harmful suspended particles. The AirgoClean® 140 E/145 E removes pathogenic viruses such as SARS-CoV-2 or the influenza virus, bacteria, fine dust, house dust, pollen, dust mite residues, mould spores or allergens from the room air just as reliably as cigarette smoke, smog and other unpleasant odours. Fully automatically, thanks to state-of-the-art air quality sensors. The air quality sensors of the AirgoClean® 140 E/145 E continuously monitor the room temperature and humidity as well as the air quality and microparticle load of the room air in order to clean it with an intelligently controlled air cleaning performance.

Request for a quote

TROTEC GMBH

Germany

We spend up to 90 percent of our lifetime indoors, at work and – for sure, in our sheltered four walls to find rest and relaxation after the strains of the day. However, many people are not aware that room air is often even more polluted than outdoor air. And even supposedly fresh outdoor air is not always as clean as it is said to be due to inner-city concentrations of fine particulate concentrations. For this reason, it is reasonable to always keep an eye on the quality of the breathing air, and to provide for healthy and clean air with the intelligent AirgoClean® 250 E air cleaner. Clean air is essential to life – but not a matter of course Dust compounds made of dead skin cells and hair can be found nearly anywhere. However, dust is not quite appealing but also functions like a magnet when attracting other pathogens.

Request for a quote

TROTEC GMBH

Germany

EFFECTIVE VIRUS AIR PURIFICATION: MODEL VARIANTS AND SPECIAL SOLUTIONSProfessional Trotec solutions for virus filtration and air pollution control No other method than the HEPA high-performance filter technology provides "as much clean air for quickly diluting the aerosol clouds" with increased safety for the optimum price/clean air ratio! To ensure that you're always provided with the precisely-tailored Trotec solution for effective virus filtration of the room air, exactly adapted to your individual safety requirement, in addition to the high-performance air purifier TAC V+ our range of products contains further model variants and special solutions. To help you integrate the TAC V+ into the respective application environment, in addition to the standard colour yellow, this device is also available painted in the colours basalt grey, white or bronze.

Request for a quote

TROTEC GMBH

Germany

No other method than the HEPA high-performance filter technology provides "as much clean air for quickly diluting the aerosol clouds" with increased safety for the optimum price/clean air ratio! To ensure that you're always provided with the precisely-tailored Trotec solution for effective virus filtration of the room air, exactly adapted to your individual safety requirement, in addition to the high-performance air purifier TAC V+ our range of products contains further model variants and special solutions. To help you integrate the TAC V+ into the respective application environment, in addition to the standard colour yellow, this device is also available painted in the colours basalt grey, white or bronze.

Request for a quote

TROTEC GMBH

Germany

AIR WASHER AW 10 SLow-maintenance 3-in-1 comfort device for air humidification and purification Usually, we spend 80 % of the day indoors, where the room air is often untreated and not ideally adapted to our natural needs. Too dry and dusty air does not only make residents but also the furniture suffer. In contrast, air that is humidified and cleaned on a natural basis is a boon: with the air washer AW 10 S you can breathe freely again and conveniently prevent colds and dry coughs caused by dried-out mucous membranes, as well as damages to furniture, parquet floors or musical instruments caused by too dry air. The AW 10 S is a 3-in-1 combination device – it does not only humidify the air by means of self-regulating cold evaporation, it also washes the air and cleans it of animal hair, house dust and pollen. Before emerging into the room the air is additionally ionised on a natural basis, whereby contaminants are neutralized and odours reduced.

Request for a quote

TROTEC GMBH

Germany

Clean breathing air the best basis for effective health prophylaxis:The TAC V+ and its model variants guarantee clean, healthier room air wherever it is needed – for mobile or stationary infection control with scientifically proven effectiveness! 99 % of all infections occur indoors. Also in the future, even in post-COVID-19 times. Clean, unpolluted breathing air is therefore essential for a good room climate and elementary health preservation. This is where the high-performance air purifiers of the TAC series offer you, your employees, customers, clients, patients and pupils a high level of protection against indirect infections by aerosol particles. The high-performance air purifier series around the TAC V+ was developed specifically for this purpose. In addition to viruses and bacteria, the TAC V+ also reliably filters respirable and harmful particulate matter (e.g. caused by road traffic) as well as pollen from the room air.

Request for a quote

ANTHERMO GMBH

Germany

Efficient use of waste heat (up to 1.000 °C) In many production processes waste heat occurs in form of hot air which is put out to the environment without any use. Very often these hot gases are contaminated air. On the other side clean (cold) air must be warmed up for the production process. In these cases cross flow heat exchanger can reduce the energy costs. The hot air stream will be conducted in the cross or counter flow method over the cold air inside the cross flow heat exchanger. Though both air streams are strictly separated because of the construction of the heat exchanger and they don´t get mixed (leakage less than 0,5 %). Only the energy of the hot waste stream is transferred to the cold clean stream.

Request for a quote

TROTEC GMBH

Germany

AIR WASHER AW 20 S3-in-1 comfort device with combined sensor and HEPA filter – our best recommendation for a perfect room climate The air we breathe is pure vital energy; its quality has a direct impact on our well-being and health. And since we breathe in about 8,000 litres of air each day – approx. 80 % of which indoors –, an ideal room air quality is a decisive factor for vigour and vitality. The air washer AW 20 S is perfectly equipped to ensure optimum room air quality at all times. In addition to the relative humidity, the intelligent combined sensor also permanently detects the particle burden of the room air and autonomously controls the automatic mode for perfectly humidified and cleaned air.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Separation of paint powder from powder coating booths. Options: Rippert powder filter This type of filter is particularly suitable for the separation of paint powder from powder coating booths and is also often used together with an upstream Rippert cyclone for powder recovery. Separation chamber with dust collecting container, filter cartridges, compressed air cleaning and sound-insulated fan are housed in a compact design. The filter cartridges are arranged vertically in order to ensure optimum cleaning behaviour and energy-efficient operation. The fan, which also comes from our own production, is characterised by smooth running and high efficiency. Standard advantages:

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

The term inline filter refers to an expandable, bolted, modular system. Depending on requirements, appropriate filter and air injection sections are connected together in series. The capacity range extends from approx. 10,000–300,000 m³/h. RS / RX filter The RS / RX series are a proven, expandable, modular system with low-pressure purge-air cleaning. Depending on requirements, appropriate filter and air injection sections are connected together in series. The capacity range extends from approx. 20,000–300,000 m³/h. RS / RX filters are suitable only for vacuum and positive pressure operation. The housing parts are usually made of 2 mm thick galvanised sheet steel. A thicker material in a painted execution as well as in stainless steel is also optionally available. The RS / RX series is 2.85 m wide. Filter hose lengths of 3 m (standard) and 4 m are available for this. The RSEC series has been designed for smaller air quantities and for above-roof installation. This series has a housing width of 2.4 m and 2 m-long filter hoses. The filter hoses are manufactured from polyester needle felt; the filtering direction is from the outside inwards. Filter cartridges and filter tubes are alternatively possible. The filter hoses are cleaned off using the material-preserving low-pressure purge-air system. The purging trolley inside the clean air compartment drives over the hose openings either continuously or controlled by pressure. In the direction of movement the first filter hose row is neutralised, while the second row is flushed from the clean air side. The third row is likewise neutralised. This results in a draught delay, which is necessary in order to allow the dislodged dust to fall into the discharge. The dust is discharged by a tried-and-tested drag conveyor with a downstream cellular wheel sluice. The return air pipes are provided with fire protection flaps and switching devices for exhaust air operation. The filter housing has been tested for resistance to pressure surges. Standard safety devices include likewise tested explosion pressure relief devices, fire extinguishing systems, mechanical and thermal monitoring systems as well as pressure-surge-resistant and flameproof cellular wheel sluices. The transport fan is arranged on the clean air side and is not exposed to swarf and dust. Hence, the conditions of a dust explosion zone do not prevail in the transport fan. RSV/RXV filter This series essentially differs from the RS/RX series in that its fans are arranged on the clean air side. RSV/RXV filters are suitable only for vacuum pressure operation. The capacity range extends from approx. 20,000 - 300,000 m³/h. The filter hoses are likewise cleaned off using the material-preserving low-pressure purge-air system.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

These are ideally suited for extraction from one or more sources of dust and are predominantly used in small and medium-sized enterprises for air quantities of up to 6,000 m³/h. ES 200P/280P deduster with jet cleaning The ES 200P deduster is designed for an air quantity of max. 3,000 m³/h and has one dust collection container; the ES 280P is designed for max. 6,000 m³/h and has two dust collection containers. The ES deduster is made of galvanised sheet steel and is a universal device for the extraction and separation of various types of swarf and dust. The raw air inlet nozzle has a non-return valve arranged upstream of the device. The filter works according to the downdraft principle, i.e. raw air is fed to the filter cartridges from above. This construction results in extremely efficient pre-filtration and preserves the filter medium. The filter cartridges are cleaned by means of compressed air impulse. Swarf and dust is collected in the mobile containers arranged underneath. The fan, which is arranged on the clean air side, is equipped with a high-performance impeller. The clean air outlet opening has a sound-absorbing lining. The electrical controller is directly attached. Equipment Optional: 280P / PAS deduster MS multi-extractor with double-walled filter sack The built-in radial fan sucks off dust and swarf at the place of generation and forces it via the impeller into the air injection frame. The swarf collects in the dust or swarf sack. The dust/air mixture flows into the filter sack, where the dust is filtered out. The cleaned air is fed directly back to the operating area. The double-walled filter sack offers a significantly larger filter area compared to other designs. Filter cartridges are also possible here as an option. The filter elements are cleaned manually. The multi-extractors are predominantly used with coarse-grained and unproblematic types of dust and swarf. The devices are not suitable for continuous operation or for wood dust and splinters. Three sizes are available for the following maximum air quantities: Type MS 160 up to 2,000 m³/h Type MS 200 up to 3,000 m³/h Type MS 250 up to 5,000 m³/h

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Type RK/RF for continuous operation, suitable for virtually all types of dust. Round filter type RK / RF The round filters from this series are suitable for continuous operation and for almost all types of dust. What is special about them is the rotary cleaning device, which causes the dust to be sucked out of the filter hoses and discharged. Using other methods the dust is also continuously dislodged from the filter element, but contaminates the other filter elements in the next moment. Only a small part of the dislodged dust falls down and is discharged. The lower part of the filter is implemented like a cyclone and acts as a pre-filter, where coarse dust is already separated and discharged. Compressed air impulse cleaning is also possible as an option here. The filtering direction of the filter hoses is from the outside inwards. The hoses are provided with support frames.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Spray walls and spray booths with dry separation via pre-filters and fine filters. Spray walls and spray booths with dry separation For lower utilisation times or overspray quantities, spraying systems with dry separation offer a meaningful alternative to water-sprinkled systems. The Rippert modular spraying system type RTS enables individual adaptation to the respective case of need. Function The overspray is caught by the exhaust air stream and fed to the filter. The solids are filtered out here, while the cleaned exhaust air is blown out into the open air by the fan. Versions The entire spray wall and the drip tray are made of galvanised sheet steel. The basic version consists of a wall with a two-fold filter stage. The attached radial fan is equipped with spark protection in the suction nozzle as well as an explosion-proof motor. The first filter stage is formed by a paper filter or a baffle plate filter, consisting of two rows of galvanised sheet metal lamellae arranged one behind the other. A glass fibre fine filter arranged directly behind it represents the second filter stage. The spray wall can additionally be equipped with removable or fixed side and ceiling panels. Each version is also available with floor suction pan, available with an integrated 2-stage filter and grating cover. Accessories In addition, the spray wall can be equipped with various accessories from the Rippert product range, such as explosion-proof lights, energy-saving flaps, turntables, etc. We recommend the installation of a supply air system for the replacement of the exhausted air. Cleaning / maintenance The spray wall is designed such that the filter elements can be exchanged with little effort in a very short time. For faster cleaning, baffle plate filters should by sprayed with a release agent (e.g. strippable varnish) before being put into operation. Underfloor paint mist extraction With dry separation, consisting of a support structure with attached paper filter, grating cover and a suction duct with air quantity adjustment.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Centrifugal force separator for powder recovery. Cyclone separator A cyclone is a centrifugal force separator and essentially consists of three parts: The intake cylinder, the cone and the immersion tube. In the intake cylinder, the air/particle mixture is brought into a circular path by means of tangential injection. Due to the taper of the subsequent cone, the speed of rotation increases sharply, so that the particles are pressed by centrifugal force against the outer wall and decelerated by friction, causing them to drop out of the air current and fall down. The cleaned air leaves the cone in an upward direction via the central immersion tube.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KALTHOFF LUFTFILTER UND FILTERMEDIEN GMBH

Germany

plane, compact design 4layer filter media coarse dust protective layer, 2 layers of activated carbon and abrasion protection layer at clean air side activated carbon layer of carbonimpregnated, reticulated PUR foam solid galvanised metal frame, with metal grids on both sides best combination of low pressure drop and adsorption capacities

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

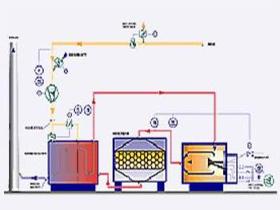

Under defined conditions, the catalytic thermal oxidizer (CTO) is an economical alternative for cleaning organic air pollutants (including VOCs). The system has proven to be particularly efficient when handling identifiable and consistent pollutant loads. In general, exhaust gases containing silicon and phosphorous cannot be treated. Under defined conditions, the Catalytic Thermal Oxidizer (CTO) is an economical alternative for cleaning organic air pollutants. The procedure is based upon the fact that under suitable conditions, even low amounts of volatile pollutants can be burnt without producing residue. This process would have required a high amount of heat energy. Therefore a catalyser and a heat exchanger are installed. The tubular heat exchanger installed behind the catalyser uses as much energy from the hot clean gases as possible in order to heat up the cold raw gases. The job of the catalyser is to decrease the amount of energy required to convert the pollutants without being depleted during the reaction. The raw gas loaded with pollutants is then forced into the heat exchangers of the CTO by the process fan. Here the raw gas is pre-heated by the hot clean gas. When required the burner heats up the exhaust gas further in the combustion chamber to the ignition temperature of the catalyser. In the catalyser the pollutants are converted into non-polluting CO2 and H20 vapour. After the catalyser, the clean gas is forced into the heat exchanger tubes. Along the way through the heat exchanger tubes the raw gases is heated and cooled. Eventually the clean gas leaves the system via the clean gas socket.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

The thermal incinerator (TI for short) is a system which converts gas or vaporous pollutants found in exhaust gas into non-polluting compounds by way of direct combustion. This machine is characterized by: The thermal incinerator (TI for short) is a proven and robust plant for the conversion of organic pollutants (VOCs, etc.). Today it is used especially for processes which involve high exposure to condensation or dust, or for specialized solutions requiring greater heat recovery potential. An example of this would be exhaust gases containing plasticizers or siloxane. The modular design of the combustion chamber and heat exchanger especially is conducive to servicing and cleaning compared to other designs. The polluted air is forced by means of a centrifugal fan into the tube bundle heat exchanger where it circulates around the tube bundle in a cross-current fashion. The heat exchanger can be designed for an efficiency of up to 70%. The pollutants are converted in the combustion chamber at a temperature of around 760 °C. After extensive heat transfer to the raw noxious gas, the cooled clean gas leaves the plant, where it can be supplied to various heat recovery systems (or a combination of several). The auxiliary burners can be operated with natural gas or propane or light heating oil.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

The regenerative thermal oxidizer from Venjakob Umwelttechnik with its low consumption of primary energy is particulary well suited to the removal of low to medium concentrations of solvend based pollutants (VOC). This machine is characterized by: The regenerative thermal oxidizer (RTO for short) embodies the state of the art technology for cleaning organic pollutants from exhaust gases (including VOCs). The systems ordinarily feature three alternately supplied heat exchanger chambers equipped with ceramic honeycombs. This material is suitable for absorbing, storing, and transferring very high amounts of heat. This allows a heat exchanger efficiency of over 95% to be achieved, so that the process temperature above 800 °C, which is required for the pollutant conversion, can be reached with a minimum of additional energy. Consequently, depending on the combustion heat of the pollutants to be cleaned, autothermal operation can be accomplished for most applications without the need for additional fuel. With careful planning, the excess heat of combustion can be effectively utilized so that the overall system can be viewed as an energy source rather than as an energy consumer. We can offer a variety of special solutions depending on the application:

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

For its exhaust gas purification systems, Venjakob Umwelttechnik offers heat exchanger systems for utilizing the waste heat. These are characterized by: We build complete heat exchanger systems for heating water, steam, air, and gas or heat transfer fluid. The residual or excess energy contained in the clean gases of the Venjakob exhaust air cleaning systems often has sufficient potential to effectively support the actual production process, the building heater or other energy consumers. Whether as an individual system for heat transfer fluid, warm and hot water, hot air, and vapor, or combined as a downstream system solution for an exhaust air purification system - the planning, construction and production of the plant are done on an individual basis.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

The adsorption system (AD) from Venjakob Umwelttechnik serves to concentrate exhaust air flows containing low concentrations of pollutants, and is particularly suitable for removing extremely low to medium concentrations of solvent-based pollutants (VOCs). This machine is characterized by: During the adsorption process, the pollutants are physically retained on the surface of a solid material (e.g. activated carbon, zeolite). The pollutants are then removed /desorbed from the zeolite by means of a small, hot stream of air. Afterwards, the flow of exhaust air from the desorption process is cleaned by means of an exhaust air cleaning system (TI, RTO, CTO). By reducing the volume and by increasing the concentration, the operating costs of the downstream exhaust gas purification system can be kept very low and make autothermal operation possible among other things The rotor is mounted vertically on a shaft with bearing and rotated slowly in the air flow. During rotation, the adsorption and desorption take place simultaneously in separate chambers with cooling on a hydrophobic (water-repellent) incombustible zeolite material. For tough applications, versions can be provided with a removable wear layer and / or higher temperatures of up to 300 ° C for desorption. Two containers are operated alternately. While one of the containers is adsorbing, the other container can be desorbed The adsorption process can be used for smoothing pollutant concentration peaks. If pollutant peaks occur during a process that could lead to a potentially explosive mixture (> 25% lower explosion limit), they cannot be introduced into an incinerator. However, the pollutants may be temporarily stored in an adsorber and then be released during the desorption phase. In certain situations, the installation of an additional fixed bed adsorber (molecular sieve) may further enhance the process (safety, operating costs).

Request for a quote

TRANSITEC ANLAGENBAU GMBH

Germany

The TransiTec pneumatic conveyor S-WS is used when, for example, local conditions do not allow the use of a spiral conveyor, for example when the minimum radius of a flexible conveyor can not be met or to overcome larger conveyor lines. Here are some features of the pneumatic conveyor: - Suitable for conveying granules and dry powders - Large filter surface - Filter cleaning by means of compressed air - adjustable interval filter cleaning - High throughput - Ideal for long conveyor lines - Fields of application: plastics and food industry as well as chemical and environmental sector. - Different filter sizes up to 10 m2

Request for a quoteResults for

Air cleaning - Import exportNumber of results

25 ProductsCompany type