- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- ac motors

Results for

Ac motors - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

This is a plastic cavity for CNC milling.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These parts were made by stainless steel and brass. The parts as the covers used for the machine.

Request for a quote

GSW SCHWABE AG

Germany

High feeding accuracy, quick cycles and simple operation Servo feeding in compact design with maintenancefree AC servo motor Fits just about any press +/ 0,025 mm feeding accuracy through incremental servo encoder Lightweight rollers with special hard chrome layer Mechanical pilot release Sturdy steel plate bolton design Height adjustment via threaded spindle Catenary rolls and edge guides at machine entrance Stock guides at exit Highperformance control with good functionality; with remote control for setup on 3,5 m cablel 24 V DC proximity switch adjustable piloting lever to be mounted to press pneumatic pilot release

Request for a quote

RUHRGETRIEBE KG

Germany

The right drive solution for every challenge: The SN3B gear series is one of the most flexible and universally usable gear series form Ruhrgetriebe. The single stage gearboxes are available with a solid or hollow shaft - with or without flange. Available are different gear- and shaft positions and a large number of different motors. SN3B-Gear types: SN3B / SN3B4 / SN3BFH / SN3BH / SN3BHFL — Motor types: AC (230/400V) and DC (180/200V) — Shaft design: Solid (SN3B /SN3B4) or hollow shaft (SN3BFH /SN3BH / SN3BHFL) — Ratios: 5; 7; 11; 12; 15; 17; 20; 24; 30; 32; 38; 50; 56; 75 — Power: 120-250W — permissible torques: 11-17 Nm — effectiv torques: 3,2-23 Nm — Additional options: brake motors, UL/CSA-certification, thermal protection, encoder Additional Data: — Ball bearings for motor and gear — Worms hardened and ground — Wormwheel made of special bronze alloy For further information see product detail page.

Request for a quote

RUHRGETRIEBE KG

Germany

The right drive solution for every challenge: The SN3F gear series impresses with its compact dimensions and flexible application range. The flange-gear is available with solid shaft as well as with hollow shaft. The geared motors are available as three-phase or direct current versions and can be equipped with brakes or pulse generators (on request). SN3F-Gear types: SN3F / SN3FH / SN3FL / SN3FLH — Motor types: AC (230/400V) and DC (180/200V) — Shaft design: Solid (SN3F / SN3FL) or hollow shaft (SN3FH / SN3FLH) — Ratios: 5; 7; 11; 12; 15; 17; 20; 24; 30; 32; 38; 50; 56; 75 — Power: 120-250W — permissible torques: 11-17 Nm — effectiv torques: 3,2-23 Nm — Additional options: brake motors, UL/CSA-certification, thermal protection, encoder Additional Data: — Ball bearings for motor and gear — Worms hardened and ground — Wormwheel made of special bronze alloy For further information see product detail page.

Request for a quote

RUHRGETRIEBE KG

Germany

The right drive solution for every challenge: The SN3VH-gearmotors impresses with its compact dimensions and flexible application range. The geared motors are available as three-phase or direct current versions and can be equipped with brakes or pulse generators (on request). SN3VH-gear types: SN3VH — Motor types: AC (230/400V) and DC (180/200V) — Shaft design: Ø14 Hollow shaft — Ratios: 5; 7; 11; 15; 17; 20; 24; 30; 32; 38; 56; 75 — Power: 120-250W — permissible torques: 11-17 Nm — effectiv torques: 3,2-23 Nm — Additional options: brake motors, UL/CSA-certification, thermal protection, encoder Additional Data: — Ball bearings for motor and gear — Worms hardened and ground — Wormwheel made of special bronze alloy For further information see product detail page.

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

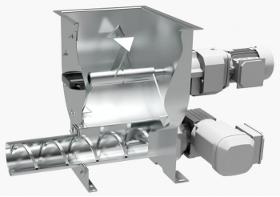

— Feeder ideal for difficult flowing, sticky or floodable bulk ingredients at low feed rates — Separate screw and agitator motors (3 phase AC gear motors), except models MT and DDSR20 — Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates Power range 1-489 dm³/h

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Stainless steel hopper with stirring — agitator for consistent screw filling and mass flow of ingredient — Separate screw and agitator motors (3 phase AC gear motors), — except model DSR28 — Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates Power range 50-7088 dm³/h

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Stainless steel hopper with stirring — agitator for consistent screw filling and mass flow of ingredient — 3 phase AC gear motors — Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates Power range 1-298 dm³/h

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Feeder ideal for difficult flowing, sticky or floodable bulk ingredients at mid feed rates — Separate screw and agitator motors (3 phase AC gear motors), except models MT and DDSR20 — Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates Power range 50-7500 dm³/h

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Feeder ideal for difficult flowing, sticky or floodable bulk ingredients at mid feed rates — Separate screw and agitator motors (3 phase AC gear motors), except models MT and DDSR20 — Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates Power range - Different Versions 4-2693 dm³/h 20 - 2693 dm³/h

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Loss-in-weight feeder for powders and pellets — Stainless steel hopper with stirring — agitator for consistent screw filling and mass flow of ingredient — Separate screw and agitator motors (3 phase AC gear motors), — Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates Power range - Different Versions 4-3743 dm³/h 20-3743 dm³/h

Request for a quote

RUHRGETRIEBE KG

Germany

Single-stage gear drive with solid shaft Gear Type: SN18 Motor Type: AC-Three-Phase 230/400V (Also available: DC 180/200V, DC-Permanent-Magnet 24V) Mounting: Gear Foot / Flange Shaft design: Solid Shaft Ø10x30 Additional Data: — Ball bearings for motor and gear — Worms hardened and ground — Wormwheel made of special bronze alloy For further information see product detail page.

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The FD-V6S has an extended degree of freedom which enables a constant torch orientation when immersing in tight work spaces. Due to the high flexibility, several of the FD-V6S robots can be placed closer together in manufacturing cells, which simplifies an increase in the number of robots per component. The most important technical data at a glance: Number of axes: 7 Working Range (P point): R 1427 mm Max. payload capacity: 6 kg Positional repeatability: +/- 0.08 mm Drive system: AC servo motor Drive power: 3600 W. Weight: 178 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The FD-H5 (H) is a compact, high-speed handling robot for small loads. A larger free space in the area of the joint creates a large arm space. Like all robots in the FD series, the H5 model also has collision protection through improved fault detection / elimination. In addition, the integrated hose package guarantees optimal protection against getting caught during the robot operation. The most important technical data: Number of axes: 6 Working range (P-Point): R 866 mm Max. payload capacity: 5 kg Positional repeatability: +/- 0.05 mm Drive System: AC Servo Motor Drive Power: 1440 W

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The FD-V166 is extremely efficient when handling heavy weights (up to 166kg). Like all robots in the FD series, the FD-V166 also has collision protection through improved fault detection / elimination. Thanks to the easily accessible cable routing, the V166 is very easy to maintain. In addition, the integrated hose package guarantees optimal protection against getting caught during the robot operation. The most important technical data at a glance: Number of axes: 6 Max. payload capacity: 166 kg Working Range (P point): R 2654 mm Positional repeatability: +/- 0.1 mm Drive system: AC servo motor Drive power: 18000 W

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The FD-V210 is extremely efficient when handling heavy weights (up to 210kg). Like all robots in the FD series, the FD-V210 also has collision protection through improved fault detection / elimination. Thanks to the easily accessible cable routing, the V210 is very easy to maintain. In addition, the integrated hose package guarantees optimal protection against getting caught during the robot operation. The most important technical data at a glance: Number of axes: 6 Max. payload capacity: 210 kg Working Range (P point): R 2674 mm Positional repeatability: +/- 0.15 mm Drive system: AC servo motor Drive power: 18000 W

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OTC DAIHEN EUROPE GMBH

Germany

The 7-axis arc welding robot V6LS from the FD series impresses with its slim design and an expanded degree of freedom, which enables a constant torch orientation when immersing in tight work spaces. Compared to the V6S, the V6LS has an extended arm, which is why the range is increased again. Due to the high flexibility, several robots can be positioned closer to each other, so it is possible to have a larger number of robots in the cell or system working together. The most important technical data at a glance: Number of axes: 7 Working Range (P-point): R 2006 mm Max. payload: 6kg Positional repeatability: +/- 0.08 mm Drive system: AC servo motor Drive power: 6000 W Weight: 316 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The FD-V350 is designed for handling tasks of maximum heavy loads. It does its job at top speed and is equally suitable for milling and grinding as well as for palletizing, gluing and spraying tasks. The fully automatic high-speed automation enables a significant increase in productivity. Synchromotion: All heavy-duty robots can be combined into complex, fully synchronized systems using the proven Synchromotion ® technology. Heavy weights: can be moved quickly and precisely. Cable routing: optimally protected, no getting caught in robot operations (integrated hose package) Easy to maintain: Easily accessible cable routing The most important technical data at a glance: Number of axes: 6 Working Range (P point): R 2771 mm Max. payload: 350 kg Positional repeatability: +/- 0.2 mm Drive system: AC servo motor Drive power: 8600 W. Weight: 1620 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The new arc welding robot FD-V8L with a refi ned design can handle all welding tasks and payloads of up to 8 kg. Due to its outstanding arm length, it is particularly suitable for large working areas. Faster cycle time: Designed for highest industrial speeds. Slim Design: Thanks to the slimmer lower arm design, less rotary motion is needed to reach the working position, thus preventing collisions with jigs and workpieces. User-friendly operation: Even the cables required for SynchroFeed are integrated into the lower arm, which prevents interference behind the robot arm. Stronger structure: Maximum payload now up to 8 kg. The use of different torches and sensors is possible. The main technical specifications at a glance: Number of Axes: 6 Max. payload capacity: 8kg Working Range (P-Point): R2006 mm Positional repeatability: +/- 0,08 mm Drive System: AC Servo Motor Drive Power: 5000 W Weight 273 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

With repetition accuracy of up to ± 0.07 mm, the new high accuracy robot can succeed in even the most demanding of tasks. The deviation from circular diameters of ≤ 10 mm is max. 0.09 mm - half as much as with commercial robots. • Position Accuracy: Highest precision regardless of robot position. • Precision machining: The best choice for laser welding and cutting, TIG, and other tasks requiring high accuracy. The best choice for laser welding and cutting, TIG, and other tasks requiring high accuracy. The main technical specifications at a glance: Number of axes: 6 Working Range (P-Point): R 1664 mm Max. payload capacity: 20 kg Positional repeatability: +/- 0,08mm Drive System: AC Servo Motor Drive Power: 7900 W Weight: 355 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The 7-axis arc welding robot B4S from the FD series is compact and, thanks to the integrated cable routing, offers optimal protection during the work process. The extended degree of freedom enables a constant torch orientation when immersing in tight work spaces. Due to the high flexibility, several robots can be positioned closer to each other, so it is possible to have a larger number of robots in the cell or system working together. The most important technical data at a glance: Number of axes: 7 Working Range (P point): R 1435 mm Max. payload: 4 kg Positional repeatability: +/- 0.08 mm Drive system: AC servo motor Drive power: 3550 W Weight: 189 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The 7-axis arc welding robot B4LS from the FD series is compact and, thanks to the integrated cable routing, offers optimal protection during the work process. The extended degree of freedom enables a constant torch orientation when immersing in tight work spaces. In addition, the FD-B4LS offers an extended arm compared to the FD-B4S and thus a larger working radius. Due to the high flexibility, several robots can be positioned closer to each other, so it is possible to have a larger number of robots in the cell or system working together. The most important technical data at a glance: Number of axes: 7 Working Range (P-point): R 2008 mm Max. payload: 4 kg Positional repeatability: +/- 0.08 mm Drive system: AC servo motor Drive power: 5650 W Weight: 321 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The FD-V50 has the highest efficiency when handling medium loads (up to 50 kg). Like all robots in the FD series, the FD-V50 also has collision protection through improved fault detection / elimination. Comparatively minimal footprint with a maximum working area. In addition, the integrated hose package guarantees optimal protection against getting caught during the robot operation. On request also with the improved protection class IP67. The most important technical data at a glance: Number of axes: 6 Max. payload capacity: 50 kg Working Range (P-point): R 2050 mm Positional repeatability: +/- 0.07 mm Drive system: AC servo motor Drive power: 14750 W Weight: 640 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The 7-axis arc welding robot V20S from the FD series is the optimal robot for medium-heavy loads. The extended degree of freedom enables a constant torch orientation when immersing in tight work spaces. Due to the high flexibility, several robots can be positioned closer to each other, so it is possible to have a larger number of robots in the cell or system working together. The most important technical data at a glance: Number of axes: 7 Working Range (P point): R 1710 mm Max. payload: 20kg Positional repeatability: +/- 0.08 mm Drive system: AC servo motor Drive power: 6600 W. Weight: 321 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The new arc welding robot, FD-V8, is equipped for all welding tasks and for load capacities of up to 8 kg. Thanks to integrated cable routing, the FD-V8 can still weld much more interference-free than any other robot in its class. It is 15% faster and the cycle times are accordingly shorter - ideal for maximum productivity. Interference-free: Interference-free welding thanks to integrated cable routing SynchroFeed-ready: Cables for the SynchroFeed / Servo-torch system can be integrated into the robot. Robot distances: Integrated cable routing enables reduced distances between the robots. Increased payload capacity: Higher load capacities of up to 8 kg. Higher performance: Up to 15% higher speeds. The main technical specifications at a glance: Number of axes: 6 Max. payload capacity: 8 kg Working Range (P point): R 1437 mm Positional repeatatbility: +/- 0.08 mm Drive System: AC Servo Motor Drive power: 3016 W Weight: 140 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The new arc welding / handling robot FD-B6 with integrated cable routing and further developed design is designed for all welding tasks and payloads up to 6 kg. Even the connections and cables required for the SynchroFeed welding process are pre-installed. Due to its outstanding arm length, it is particularly suitable for large work areas • Higher clock speeds for highest industrial speeds • Slim design: Integrated wrist motors prevent malfunctions from devices and workpieces. • User-friendly: Integrated supply lines prevent faults behind the robot arm. • Suitable for up to 6 kg payload capacities. Ideal for corresponding handling applications. Number of axes: 6 Max. payload capacity : 6 kg Working Range (P point): R 1445 mm Positional repeatability: +/- 0.08 mm Drive system: AC servo motor Drive power: 3132 W Weight: 278 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The new arc welding / handling robot FD-B6 with integrated cable routing and further developed design is designed for all welding tasks and payloads up to 6 kg. Even the connections and cables required for the SynchroFeed welding process are pre-installed. Thanks to higher process speeds and shorter cycle times, the FD-B6 fulfills all requirements for the most demanding handling tasks. • Higher clock speeds for highest industrial speeds • Slim design: Integrated wrist motors prevent malfunctions from devices and workpieces. • User-friendly: Integrated supply lines prevent faults behind the robot arm. • More stable construction: 1.5 times the load capacity for welding tasks with different ranges. Number of axes: 6 Max. payload capacity : 6 kg Working Range (P point): R 1445 mm Positional repeatability: +/- 0.08 mm Drive system: AC servo motor Drive power: 3132 W Weight: 145 kg

Request for a quote

MERKES GMBH - SMALL MOTORS

Germany

The synchronous servomotors of the series MT are brushless permanent magnet synchronous servomotors with sinusoidal back EMF and with neodym permanent magnets at the rotor. Therefore they are particulary suitable for high-quality servo applications, for example positioning demanding high standards of dynamics and accuracy. Standard configuration of the motors: 2-pole resolver feedback connectors, straight, 1" flange design B5 thermo protection PTC protection class IP65 plain shaft RAL 9005 Further options and equipment are available on request. Maybe options and non-standard equipment can have an effect on the dimensions of the motors. We therefore recommend to consult about it with us before ordering.

Request for a quoteResults for

Ac motors - Import exportNumber of results

35 ProductsCompany type