- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- blender

Results for

Blender - Import export

WHITE STEEL GMBH

Germany

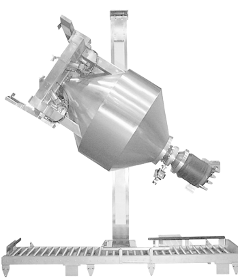

Is widely used in Pharmaceutical, Cosmetics, Food and Chemical industries etc. It is suitable for mixing dry powder or granular materials with perfect flowing properties. Servo conveyor system Base holds the mixing vessel which made of stainless steel (304) Cylindrical vessel with two conical bases. The vessel rotates on horizontal axis. And the Inner edges wrapped to prevent accumulation of the material. Circular cover, sealed with silicone gasket Discharge hole fitted with manual butterfly valve Guardrail (Profile) connected to a safety sensor to prevent the vessel from rotation while opening the rail Sensor system stops the mixer in the desired position (The discharge hole to the bottom) Available certification up on your request: UL, CE, GMP, FDA, ASME. Available documents up on your request: I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

MIXACO MASCHINENBAU

Germany

By means of the moveable container with the mixed material, container with separate trolley, will be positioned in the tumbling mixer. The moveable container will be lifted by a pneumatic stamp. The trolley will be fixed in the tumbling mixer by means of a pneumatically actuated draw-in device. The head of the tumbling mixer formed as a container, fixed on the mixing head with four pneumatically operated clamping jaws including forklift pockets and discharge valve. The lifted container is locked to the tumbling head by means of pneumatically actuated locks. After fixing of the container at the tumbling head a SPS controlled tumbling process starts.

Request for a quote

MIXACO MASCHINENBAU

Germany

Gentle Mixing Without Tools MIXACO Revolution™ is mixing system that functions without tools. Gentle mixing of materials during rotation of the container is achieved with built-in mixing segments. This technology without driven mixing tools prevents additional thermal stress for the product. All Benefits at a Glance •Gentle homogenization •No inadvertent warming of mixing materials •No abrasion of granulates •Double-walled mixing vessel allows temperature-controlled mixing •Energy-efficient through low drive power consumption •100% discharge by pivoting to discharging position •Good accessibility for fast, easy cleaning •Tool-free design makes maintenance easy •Suitable for ATEX applications (up to Zone 20 without inertization of protective gases)

Request for a quote

MIXACO MASCHINENBAU

Germany

The Robust Workhorse: The high-performance MIXACO universal mixer is ideal for many different applications. Whether slow, gentle homogenization or thorough mixing is required, consistently high quality is guaranteed for every mixing process. In particular, the universal mixer’s highly flexible design possibilities enable it to be adapted easily to suit the required mixing task and individual on-site requirements. The MIXACO universal mixer is available in sizes from 20 to 6,000 liters. All Benefits at a Glance •Can be used for a wide variety of applications, such as homogenization, dispersion, coating or granulation •Mixer tools optimized for the individual mixing task •Performance-optimized selection of mixing drives ensures high energy efficiency •Rapid cleaning possible when pivoting mixer lid is open •Double-walled mixing vessel enables ideal temperature control of product during mixing •ATEX version possible

Request for a quote

MIXACO MASCHINENBAU

Germany

MIXACO Container Mixer i4MIXACO has been an innovation leader in the mixing industry for years. With the innovative container mixer i4 we are going one step further into the future. Outstanding mixing flexibility, high quality and reduced cleaning effort to a minimum are its outstanding features. Equipped with the new MIXACO Control Center (MCC) we set a new milestone for highly efficient mixing plants. All advantages at a glance * Flat mixing head * Optimized suction * Dust protected machine components * injection through mixer shaft * different container sizes on one mixer * Reduction of cleaning times * Lifting device with container positioning * High flexibility * New tools for more efficient mixing * Lower energy consumption * No base plate

Request for a quote

WITT-GASETECHNIK GMBH & CO KG

Germany

The use of protective gases is an essential element of precise quality control (HACCP) in food packages (Modified Atmosphere Packaging = MAP). MAP gas mixers by WITT provide controlled gas quality and safety in your packaging process – for germfree and preserving food. WITT offers gas mixing and metering systems for all packaging machines used in the food industry, no matter if vacuum packaging, thermo forming, flow pack or chamber packaging machine. The gas mixing systems are adjusted to your specific product type and processing and require only basic installation requirements. WITT system solutions are developed in close collaboration with national food and research institutes. WITT is approved and certified according to ISO 22000 for food safety.

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Customize foundation application with ultra-pure and hypoallergenic materials Ultra-pure and hypoallergenic, POREX® foam applicators and blenders are designed exclusively for skin contact, perfect for personal care applications - including powdered makeup, liquid foundation, skin care moisturizers and self-tanners. Available in custom colors and shapes, our foam applicators and blenders: Offer “buildable” application of makeup – Material enables sheer to full coverage. Soft to the touch– Soothing and friendly to the skin

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Customize foundation application with ultra-pure and hypoallergenic materials Ultra-pure and hypoallergenic, POREX® foam applicators and blenders are designed exclusively for skin contact, perfect for personal care applications - including powdered makeup, liquid foundation, skin care moisturizers and self-tanners. Available in custom colors and shapes, our foam applicators and blenders: Offer “buildable” application of makeup – Material enables sheer to full coverage. Soft to the touch– Soothing and friendly to the skin

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Customize foundation application with ultra-pure and hypoallergenic materials Ultra-pure and hypoallergenic, POREX® foam applicators and blenders are designed exclusively for skin contact, perfect for personal care applications - including powdered makeup, liquid foundation, skin care moisturizers and self-tanners. Available in custom colors and shapes, our foam applicators and blenders: Offer “buildable” application of makeup – Material enables sheer to full coverage. Soft to the touch– Soothing and friendly to the skin

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Customize foundation application with ultra-pure and hypoallergenic materials Ultra-pure and hypoallergenic, POREX® foam applicators and blenders are designed exclusively for skin contact, perfect for personal care applications - including powdered makeup, liquid foundation, skin care moisturizers and self-tanners. Available in custom colors and shapes, our foam applicators and blenders: Offer “buildable” application of makeup – Material enables sheer to full coverage. Soft to the touch– Soothing and friendly to the skin

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Customize foundation application with ultra-pure and hypoallergenic materials Ultra-pure and hypoallergenic, POREX® foam applicators and blenders are designed exclusively for skin contact, perfect for personal care applications - including powdered makeup, liquid foundation, skin care moisturizers and self-tanners. Available in custom colors and shapes, our foam applicators and blenders: Offer “buildable” application of makeup – Material enables sheer to full coverage. Soft to the touch– Soothing and friendly to the skin

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Customize foundation application with ultra-pure and hypoallergenic materials Ultra-pure and hypoallergenic, POREX® foam applicators and blenders are designed exclusively for skin contact, perfect for personal care applications - including powdered makeup, liquid foundation, skin care moisturizers and self-tanners. Available in custom colors and shapes, our foam applicators and blenders: Offer “buildable” application of makeup – Material enables sheer to full coverage. Soft to the touch– Soothing and friendly to the skin

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Customize foundation application with ultra-pure and hypoallergenic materials Ultra-pure and hypoallergenic, POREX® foam applicators and blenders are designed exclusively for skin contact, perfect for personal care applications - including powdered makeup, liquid foundation, skin care moisturizers and self-tanners. Available in custom colors and shapes, our foam applicators and blenders: Offer “buildable” application of makeup – Material enables sheer to full coverage. Soft to the touch– Soothing and friendly to the skin

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple ointment viscosity and types Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION The 3D blender is widely used in pharmacy, chemical industry, food industry, scientific research, ect… It is suitable for blending drypowder or granular materials with good flowing properties. Powder can be loaded into the 3D blender through a wider opening manhole Multidirectional motion mechanism for a better blending process Final product can be discharged through a butterfly or slide valve Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple ointment viscosity and types Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Is widely used in Pharmaceutical, Cosmetics, Food and Chemical industries etc. It is suitable for mixing dry powder or granular materials with perfect flowing properties. Servo conveyor system Base holds the mixing vessel which made of stainless steel (304) Cylindrical vessel with two conical bases. The vessel rotates on horizontal axis. And the Inner edges wrapped to prevent accumulation of the material. Circular cover, sealed with silicone gasket Discharge hole fitted with manual butterfly valve Guardrail (Profile) connected to a safety sensor to prevent the vessel from rotation while opening the rail Sensor system stops the mixer in the desired position (The discharge hole to the bottom) Available certification up on your request UL, CE, GMP, FDA, ASME.

Request for a quote

SERVOLIFT GMBH

Germany

The bin blender is a special form of free-fall blender. Bin blenders are used wherever the volume of usually available containers are not sufficient for the batch, or the given process requires a fixed clamped blending container. The design of the bin blender can be customized to customer specifications. Whatever the bin shape - square, rectangular, round with a cone, double cone - symmetrical or asymmetrical, V-container - all these bin blenders from SERVOLIFT can be extended in order to perform the installation and extension functions as with typical container blenders. This includes an optional and useful WIP cleaning to clean the blender chamber. Blend in customer-specific containers Technical description Stainless steel or cGMP-compliant design Free-standing or floor- or ceiling-mounted design Loading using docked containers, vacuum transport systems, gravimetric feeding and discharging. Dosing systems for discharging Safety housing depending on where set up, and...

Request for a quote

SERVOLIFT GMBH

Germany

SERVOLIFT’s drum blender is designed for the demands of the pharmaceutical and chemical industries. Equipped with easy-to-use equipment, optimal ergonomics, converted to a space-saving and compact machine housing. The blender offers the ability to take up drums of varying sizes. The drum blender can be ideally connected to previous or follow-on processes, to refill or sieve into underneath placed containers, for easy attachment of drums either manually or hydraulically, to blend various containers with fitting clamp or take-up systems. Blending and Handling Technical description Stainless steel or cGMP-compliant design Can lift all customary drums as well as special drums Free-standing or floor- or ceiling-mounted design Loading using trolleys, hand lifters up to fully automatic roller conveyor feeds and unloading Various container clamping systems, from manual up to fully automatic designs Safety housing depending on where set up, and processes Standard tipping setting on the...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SERVOLIFT GMBH

Germany

SERVOLIFT laboratory blenders are ideal for producing small batches under production conditions. This is possible through the container’s geometry, which is adapted from the large production blender. The knowledge gained from blending tests creates a reliable basis for later manufacturing. Parameters such as RPM and time can therefore be varied. Small size - large effect Technical description Compact blender, ideal for product and process development Operate on a control or touch panel Design and geometric relationships correspond to the large production blenders Also available as test and loan unit

Request for a quote

SERVOLIFT GMBH

Germany

SERVOLIFT container blenders are specially designed for gentle product blending and flexible pick up of various containers. The hydraulic clamping system ensures absolutely secure take-up of the blending container. The PLC and recipe-controlled blending process provides optimal adaptation to the blended goods. The Servolift horizontal clamp bar system easily picks up various container sizes or adapters for drums and small containers. The ability to extend the handling functions of lifting, lowering, inverting, pivoting the blender columns provides many applications for the container blender. This is extended through optional installed and auxiliary systems such as automatic feed and unloading, chopping in the blending container, spray system to add liquids to the blended product, prior and follow-on weighing machinery, dosed unloading, NIR systems, etc.. Blend in a closed system Technical description Stainless steel or cGMP-compliant design Take up blending containers which are...

Request for a quote

WITT-GASETECHNIK GMBH & CO KG

Germany

WITT offers high-quality gas mixers / gas blenders and gas metering systems for two or more gases, for high flow rates and highly fluctuating gas withdrawals. You can choose between various options: According to your requirements, WITT gas mixers / gas blenders are available for nearly all technical gases and flow rates: for the optimal gas mixture for welding applications, the required gas concentration for food packages (modified atmosphere packaging = MAP) or the production of synthetic air for medical applications. State-of the art mechanical or electronic gas mixing systems provide accuracy and process safety. You can also control your gas mixing systems conveniently via Intranet, Internet or mobile devices. Combinations of WITT gas mixers / gas blenders with other WITT quality products such as gas analysers are also possible. They can be manufactured as complete system solutions.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

With the volumetric dosing and mixing station SPECTROCOLOR V, motan offers a simple solution for the economic production of plastics parts: precise dosing and homogeneous mixing with highest repeatability. Our unique gravity-mixing principle offers you a high consistency of mix for all the components before they reach the extruder. This plays a key role in guaranteeing you perfect plasticization and homogenization of the materials. SPECTROCOLOR V doses and mixes all easy to normal flowing granular materials. Up to six dosing modules, supports both flood-fed and starve-fed extrusion.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

GRAVICOLOR doses and mixes up to six materials precisely and with maximum recipe accuracy. These modular gravimetric units are designed for injection, blow moulding and extrusion and provide throughputs up to 2200 kg/h. Independent of recipes, materials, or the operational environment, IntelliBlend analyses all process data achieving the best possible operating point at any time through continuous self-optimisation. Recipe integrity results in excellent and consistent product quality. The GRAVICOLOR series is part of the motan range of products and systems for all stages of management, conditioning and preparation of plastic granules. The design quality, plus the engineering, ensures high performance and reliable operation.

Request for a quote

MÜLLER GMBH

Germany

Müller drum and container blenders - almost like plug and play. Blender or blending column, drum or container – bulk solids such as granules or powders are mixed reliably by an intelligent system; which if required can provide a data report for tracking blender settings such as weight, mixing times and number of revolutions. You therefore have complete documentation for your quality assurance system. Müller drum and container blenders are adaptable for your processes: Gentle action Highly effective Safe Blending parameters can be set With data report Blending column with weighing facility Container tumbler FTHMW 1500 MG8 Lifting weight 1500 kg Height 6 m Design: tumbling and weighing - fully automatic emptying Container Blender Lift / swivel / tumble column Type FTHMS 600 MG7 Loads up to 600 kg Column height 4.0 m Design: motorized lift, swivel, grip and tumble actions Stationary blender for drums Tumbling stand Type FTMh 300 MG1 Loads up to 350 kg Height of unit 1.6...

Request for a quoteResults for

Blender - Import exportNumber of results

24 ProductsCountries

Company type