- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- big bag filling

Results for

Big bag filling - Import export

IFA TECHNOLOGY GMBH

Germany

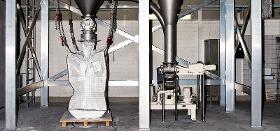

We consider your individual requirements and build customised big bag stations for you. Our big bag stations are characterised by particularly user-friendly handling. In order to minimise dust and dirt, the docking system from IFA Technology makes it possible to fill or empty the big bags virtually dust-free. The integrated controller guarantees accurate and calibratable bagging of solids and bottling of liquids. We design big bag filling stations or big bag emptying stations according to your requirements and offer you manual or fully automated stations.

Request for a quote

BEHN + BATES MASCHINENFABRIK GMBH & CO. KG

Germany

For the smooth processing of your big bags we offer different machine variants allowing to fill powders & flours as reliably as grains & granules. Furthermore our delivery programme includes a large variety of accessories, e. g. automatic pallet separator, cover sheet dispenser or full pallet transport systems.

Request for a quote

SRK SOBERNHEIMER ROHSTOFF-KONTOR GMBH

Germany

Our machinery enables great flexibility at constantly high throughput to recycle your plastic waste efficiently and recourse-saving with help of different recycling processes Currently we run two modular recycling lines for clean, single-polymer and thermoplastic waste. One shredding-grinding line for up to 6.000 tons yearly and one modular shredding-grinding-agglomeration line for up to 9.000 tons which enables parallel or in-line grinding and agglomeration. With those two lines we can process any plastic waste the optimal, resource-efficient way. Since the foundation in 1997 we have developed a deep process knowledge for many types of plastic waste, to produce non-cloggy, free-flowing and dry regrind and agglomerate. After every polymer change our recycling lines are cleaned meticulously to avoid contamination from a polymer-mix. All metal parts are detected by metal detection and the recyclate runs through a dedusting machine before being filled into big bags.

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Big Bag Fill The filling plant for Big Bags and octabins Our Big-Bag filling scales enable the external assignment of filling services onto calibrated Big-Bag scales from storage silos bags or drums. We offer short term useful and flexible filling capacities as a replacement or supplement to your own filling plants. Technical data Big Bag sizes: 0.5-2.5 m³ Weight ranges 50-1,500 kg Product-contacting parts: Stainless steel Feeding: From 100 m³ silos, from palletted bagged goods and drums Number of filling lines 4 Areas of application Filling of Big Bags from silo Filling of Big Bags from bags Refilling of various sizes of Big Bag De-aeration of the product, with subsequent Big-Bag filling Refilling with protective screening Refilling with crushing of agglomerates Refilling with homogenization Refilling with additional admixture of one or more components Refilling with metal detection Prospect for download

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Drug Mill The economic solution for grinding your natural products The drug mill used by us enables an economical external grinding of leaf drugs, herbs and plant roots for our customers. This way our clients save having to invest in their own, only mills that would only be fully utilized seasonally – at the same time they remain flexible with the production of teas, remedies or natural cosmetics. Technical data Throughput: 0,5-3 to/h Target fineness: 1-15 mm Product-contacting parts: Stainless steel Cleanability: Completely cleanable Grinding plant: Granulator with screen insert Feeding: Via bunker with clearing device and double shaft screw Container: Feeding as bagged goods, bales, Big Bags, octabins or in drums Areas of application Grinding of drug precursors Grinding of willow bark Grinding of St. John's wort Grinding of tea leaves Grinding of plant roots After grinding, filling in Big Bags or other containers Prospect for download

Request for a quote

B+B ANLAGENBAU GMBH

Germany

An automatic big bag filling station supplied by B+B completes the washing line of the plastic recycling process. Inquire for more information on options.

Request for a quote

TRANSITEC ANLAGENBAU GMBH

Germany

The TransiTec Big Bag filling stations are suitable as standard for filling big bags with a capacity of up to 2 tons. Various options are available to meet the required task. Also a calibratable weighing of the filled Big-Bas. The Big-Bag filling station offers a variety of options: - height-adjustable suspension frame - Tightening of the big bag by means of linear drive - Double big bag filling - vibration table for compacting the products, etc., ... to name just a few.

Request for a quote

TRANSITEC ANLAGENBAU GMBH

Germany

Our big bag emptying stations are generally designed for big bags with a capacity up to 2 tons. Different alternatives and options are available to meet customer’s requirements. In case of a big bag emptying station for bad flowing products, we can provide a vibrating frame as well as a massaging system with pneumatically operated cylinders to enhance the discharge (or a combination of both systems in the worst case). The design of this station will allways depend of the characteristics of the product which has to be discharged. The big bag emptying station is provided with a lifting frame, adjustable in height, with automatic big bag tension device which allows a completely emptying of the bag. How it works: by loosing weight during emptying, the big bag will be tensioned automatically by a telescoping spring system. Optionally, we offer the possibility to shut even partially filled big bags.

Request for a quote

BEHN + BATES MASCHINENFABRIK GMBH & CO. KG

Germany

Bag filling with the BEHN + BATES impeller packer is achieving best filling results due to low-air filling and high filling pressure

Request for a quote

BEHN + BATES MASCHINENFABRIK GMBH & CO. KG

Germany

The continuous product flow from the filling chamber is ensured by the fluidization air quantities being adjustable to your product. For compact bag shapes the special BEHN + BATES filling de-aeration nozzle removes the air from the bag already during filling.

Request for a quote

BEHN + BATES MASCHINENFABRIK GMBH & CO. KG

Germany

The continuous product flow from the filling chamber is ensured by the fluidization air quantities being adjustable to your product. For compact bag shapes the special BEHN + BATES filling de-aeration nozzle removes the air from the bag already during filling.

Request for a quote

CATUR JAYA GMBH

Germany

Big bags with a capacity of 1 Ton are an indispensable solution in construction, agriculture and bulk industrial raw material processing where batch delivery is required to site. The pictures here serve as a sample for custom made design possibilities and use.

Request for a quote

HELIOS GERÄTEBAU FÜR KUNSTSTOFFTECHNIK GMBH

Germany

OKTOMAT® ECO is an emptying station for the automatic emptying of Octabin and BigBags. A pallet jack is enough to move the container under the emptying station. The bulk bags can be completely and trouble-free emptied from above. The OKTOMAT® uses a vibrating suction head and the automatic bag tightening mechanism pulls the foil inlet or BigBag upwards. The material flows towards the middle and is continuously sucked. The ECO series is the basic model of the OKTOMAT® emptying stations and is ideally suited for the majority of applications dealing with free-flowing to poorly flowable materials. OKTOMAT® emptying stations are easy to use, low maintenance, robust and durable. Due to its pedestal form, the ECO is particularly space-saving in width, the height is individually adjustable.

Request for a quote

HELIOS GERÄTEBAU FÜR KUNSTSTOFFTECHNIK GMBH

Germany

OKTOMAT® SOS is an emptying station for the automatic emptying of Octabin and BigBags. A pallet jack is enough to move the container under the emptying station. The bulk bags can be completely and trouble-free emptied from above. The OKTOMAT® uses a vibrating suction head and the automatic bag tightening mechanism pulls the foil inlet or BigBag upwards. The material flows towards the middle and is continuously sucked. The SOS series with its full equipment is ideally suited for the majority of applications and difficult tasks. The integrated oscillating systems for foil / BigBag tightener and suction head enable the emptying of free-flowing to heavily bridge-forming materials. Due to its pedestal form, the OKTOMAT® SOS is particularly space-saving in width, the height is individually adjustable. OKTOMAT® emptying stations are easy to use, low maintenance, robust and durable.

Request for a quote

BAUER GMBH

Germany

-sturdy steel construction -suitable for crane and fork lift trucks -pick-ups for BIG-BAGS

Request for a quote

HELIOS GERÄTEBAU FÜR KUNSTSTOFFTECHNIK GMBH

Germany

OKTOMAT® SOS Classic is an emptying station for the automatic emptying of Octabin and BigBags. A pallet jack is enough to move the container under the emptying station. The bulk bags can be completely and trouble-free emptied from above. The OKTOMAT® uses a vibrating suction head and the automatic bag tightening mechanism pulls the foil inlet or BigBag upwards. The material flows towards the middle and is continuously sucked. The SOS series with its full equipment is ideally suited for the majority of applications and difficult tasks. The integrated oscillating systems for foil / BigBag tightener and suction head enable the emptying of free-flowing to heavily bridge-forming materials. Due to its portal form it is particularly space-saving in depth and the increased tension force allows even high-density materials to be emptied without a problem. OKTOMAT® emptying stations are easy to use, low maintenance, robust and durable.

Request for a quote

HELIOS GERÄTEBAU FÜR KUNSTSTOFFTECHNIK GMBH

Germany

OKTOMAT® SOS is an emptying station for the automatic emptying of Octabin and BigBags. A pallet jack is enough to move the container under the emptying station. The bulk bags can be completely and trouble-free emptied from above. The OKTOMAT® uses a vibrating suction head and the automatic bag tightening mechanism pulls the foil inlet or BigBag upwards. The material flows towards the middle and is continuously sucked. The SOS series with its full equipment is ideally suited for the majority of applications and difficult tasks. The integrated oscillating systems for foil / BigBag tightener and suction head enable the emptying of free-flowing to heavily bridge-forming materials. Due to its pedestal form, the OKTOMAT® SOS is particularly space-saving in width, the height is individually adjustable. OKTOMAT® emptying stations are easy to use, low maintenance, robust and durable.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Big bag filling - Import exportNumber of results

18 ProductsCountries

Company type

Category

- Bag filling machinery and equipment (5)

- Plastics - machines and material for industry (4)

- Handling - Machines & Equipment (2)

- Construction - Machines & Equipment (1)

- Goods handling systems, continuous (1)

- Lifting equipment - accessories (1)

- Plastics - industrial raw materials (1)

- Recycling - machines and installations (1)