- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- monitor

Results for

Monitor - Import export

FLUKE PROCESS INSTRUMENTS GMBH

Germany

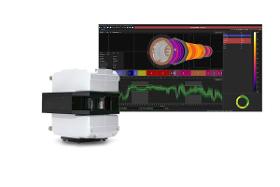

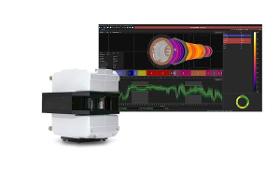

The CS400 Kiln Shell Imaging System relies on the MP Linescanner, which provides continuous, accurate and real-time thermal images and temperature measurements for moving processes. With the ability to scan up to 1024 data points in a single scan, the MP Linescanner can provide a complete picture of even the highest speed manufacturing processes, ensuring an accurate temperature reading. Key Features: Multiple kiln support Added ThermoView TV40 Thermal Imager support (Additional hardware required) Added Pyrometer support – including Mi3 and Endurance units – for Burn Zone and Shadow monitoring (additional hardware required) Analog and Digital I/O (Wago) “One brick” resolution hot spot detection, even in shadowed areas CS400 System Software The CS400 Kiln Shell Imaging System features specially designed software, which relies on standard Ethernet ports. Because the graphic user interface is designed specifically for kiln applications

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

By using an array of sophisticated sound sensors, the SV600 can be mounted close to any equipment or asset, to any area of the production line, or where human access is restricted or dangerous to ensure you can monitor the most important parts of your facility without interruption. As a fixed, automated solution, the SV600 integrates with your process and eliminates the need for lengthy fault-finding processes such as soapy water tests, when used as part of your product leak testing process. By continuously monitoring your environment, you can quickly detect and fix air leaks – reducing your consumption of compressed air and energy to help save your facility money. Key Features: High-end 24/7 acoustic monitoring 64-Digital MEMS microphones placed in a Sunflower Array Integrated visual light camera Powerful processor for onboard real time processing Sound classification Frequency filtering dB values and sound intensity mapping Event triggering

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

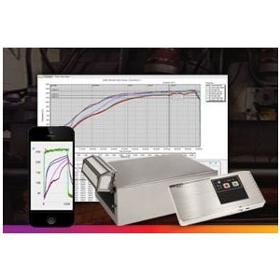

The Datapaq TP6 is the perfect solution for the most demanding high temperature profiling applications with a 316-grade machined stainless-steel case and IP67 rating. Its robust software options also allow you to read information from the data logger in real-time with the optional Radio Frequency (RF) system and USB/Bluetooth connection options. • Available in 10 and 20 channel configurations and two case styles • Water resistant (IP67 rated) • ATEX certified version available, allowing for safe operation in Zone II classified areas • Communication via USB or Bluetooth • Real time telemetry via USB, RF telemetry and Bluetooth* • Alkaline, NiMH and Lithium battery options • Compatible with the Datapaq Insight™ for mobile application

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

• Real-time thermal imaging, scan speed up to 300 Hz • Up to 1024 measurement points per line • Wide choice of spectral and temperature ranges • High-quality brushless motor (MTBF 40,000 h) • Built-in Ethernet TCP/IP communications • PC independent alarm output • PC independent 4-20 mA interfaces (3 outputs) • I/O module support for up to 10 sectors/zones (PC independent) • Internal Line Laser for accurate alignment • Rugged, waterproof IP65 enclosure • Air purge keeps window free of dirt and condensation • Built-in water cooling for ambient up to 180 °C (356 °F)

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The CS400 Kiln Shell Imaging System relies on the MP Linescanner, which provides continuous, accurate and real-time thermal images and temperature measurements for moving processes. With the ability to scan up to 1024 data points in a single scan, the MP Linescanner can provide a complete picture of even the highest speed manufacturing processes, ensuring an accurate temperature reading. Key Features: — Polar charts highlighting coating thickness and brick thickness — Envelope profiles – including alarm functionality – over the entire kiln — Built-in, on-network storage to store historical data — Free scalable AOIs (areas, line and slice) including temperature trend analysis — Virtual 3D walkthroughs across the entire kiln — 3D views available per each defined kiln zone — Easy-to-use software configurations that showcase the scanner position relative to the kiln — Flexible image sizing and configurable orientations of rotation — Fail-safe “hot spot” alarm outputs

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Kiln shell temperatures are monitored along the entire length of the kiln. The infrared line-scanning system detects kiln hot spots due to refractory loss, damage, or wear. Data from up to 4 scanners or individual point sensors (optionally used to monitor the burning zone and tire slips) can be seamlessly integrated into one complete thermal image. Detect abnormal operating conditions such as faulty flame position and shape! Optimize and manage kiln maintenance! Extend the operational life of kiln and refractory! Automated kiln and refractory monitoring Visualisation on PC Ethernet TCP/IP interface PC-independent alarm output Analog outputs 3 x 4 – 20mA To ensure reliable operation in even the harshest kiln environments, the MP150 linescanner, which is used in the CS210 thermal imaging system system, is designed with a rugged cast aluminum housing and mounted in a robust stainless-steel enclosure.

Request for a quote

INTERACTIVE SCAPE GMBH

Germany

Professional multi-touch screens and monitors with Ultra HD / 4K UHD display and integrated object recognition, P-Cap technology with up to 80 touch points, response times of max. 5 milliseconds

Request for a quoteResults for

Monitor - Import exportNumber of results

8 ProductsCountries

Company type