- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- image images

Results for

Image images - Import export

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The ThermoView TV40 is a high-performance industrial fixed thermal imaging system that allows you to expand your understanding by providing continuous infrared and visual feeds to visualize temperature data. The TV40 offers a fully integrated temperature control, monitoring, and data archiving solution. With the ability to personalize your integration, the TV40 allows you to automate your process by programing unlimited "areas of interest," programable alarms, utilize advanced pass/fail logic, and perform safety or asset inspections. Feed the data to your PLC or view feeds remotely. Hardware The rugged TV40 thermal camera lets you visualize the temperature data you need anywhere in your process with reliable, high-quality 320x240 and 640x480 infrared resolution options. Several key features: IP67 (NEMA 4) housing that guarantees long-term thermal imaging in the harshest environments (air purge and other accessories available) Simultaneous infrared and visible sighting

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

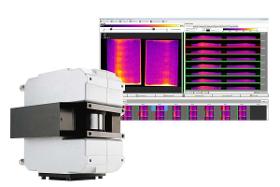

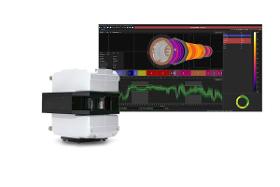

By using an array of sophisticated sound sensors, the SV600 can be mounted close to any equipment or asset, to any area of the production line, or where human access is restricted or dangerous to ensure you can monitor the most important parts of your facility without interruption. As a fixed, automated solution, the SV600 integrates with your process and eliminates the need for lengthy fault-finding processes such as soapy water tests, when used as part of your product leak testing process. By continuously monitoring your environment, you can quickly detect and fix air leaks – reducing your consumption of compressed air and energy to help save your facility money. Key Features: High-end 24/7 acoustic monitoring 64-Digital MEMS microphones placed in a Sunflower Array Integrated visual light camera Powerful processor for onboard real time processing Sound classification Frequency filtering dB values and sound intensity mapping Event triggering

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The TIP900 system is a comprehensive thermal imaging and noncontact profiling system designed to supervise the temperature of wallboards coming out of the oven. It uses an infrared thermal imager to continuously scan the entire board surface temperatures and allows the detection in real time of moisture and density variations inside each board. The powerful TIP900 software provides sophisticated data integration, visualization and event analysis, and offers users a complete solution of real-time monitoring, detection and traceability. It also analyzes and provides optimal oven dryer profile balance. The detailed wallboard quality maps, the historical temperature trend charts and the images can be seen locally at the operator workstation or remotely. All data is stored in the LogViewer database for complete process visibility and long term traceability. TIP900 System Software Detailed continuous board quality monitoring (100% of all board images are archived)

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The CS400 Kiln Shell Imaging System relies on the MP Linescanner, which provides continuous, accurate and real-time thermal images and temperature measurements for moving processes. With the ability to scan up to 1024 data points in a single scan, the MP Linescanner can provide a complete picture of even the highest speed manufacturing processes, ensuring an accurate temperature reading. Key Features: Multiple kiln support Added ThermoView TV40 Thermal Imager support (Additional hardware required) Added Pyrometer support – including Mi3 and Endurance units – for Burn Zone and Shadow monitoring (additional hardware required) Analog and Digital I/O (Wago) “One brick” resolution hot spot detection, even in shadowed areas CS400 System Software The CS400 Kiln Shell Imaging System features specially designed software, which relies on standard Ethernet ports. Because the graphic user interface is designed specifically for kiln applications

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Thermal imaging system based on the Raytek MP150 infrared linescanner. Detailed web temperature profile based on 40,000 measurement points per second Automated temperature monitoring Automated quality monitoring for ISO9000 Ensures proper web temperatures for strong film-to-substrate adhesion Enables plant operators to reduce scrap and improve profitability and product quality Quick and automatic detection of “wavy” or “running” edges, gaps, and torn edges Define product-specific configurations (recipes) Automatically analyze “automatic sector” temperature distributions Visualisation on PC Playback stored files as “movie” Multiple language support Integrated OPC server for remote system control Ethernet TCP/IP interface integrated in the line scanning system PC-independent alarm output Analog outputs 3 x 4 – 20mA Analog or digital output modules For sheet extrusion see the Raytek ES150 system.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The Raytek MP150 infrared linescanner is designed for temperature monitoring in demanding industrial environments. It generates accurate thermal images of moving objects, scanning up to 90° wide fields of view with a motorized mirror at up to 1024 points per line and at a max. 150 Hz frequency. An internal high-speed microprocessor calculates the temperature of the individual measurement points. — Real-time thermal line-scanner system for continuous or discrete process measurements — Optical resolution up to 200:1 — Built-in line laser for rapid alignment — On-board Ethernet TCP/IP communication — Wide choice of models and spectral responses The Raytek MP150 includes provision for air or water-cooling, three configurable analog outputs, and two-way digital communications. It can be used in standalone mode, connected to a single PC or integrated into a process control system using the Windows-based DataTemp DP software for remote configuration and real-time process monitoring.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Thermal imaging system based on the Raytek MP150 infrared linescanner Automatic temperature and quality monitoring in continuous web processes Detect thermal problems early Faster product changes and reduced setup time Communicate with process control system via OPC Reduce scrap APPLICATIONS Plastics, metals, paper, and building industries, combustion prevention, hotspot detection, flat and float glass production, automotive, food processing and numerous other industrial applications FEATURES Onboard Ethernet TCP/IP communication Product specific configurations or “recipes” Custom measurement sectors Optional analog and digital outputs for each sector Analog outputs 3 x 4 – 20mA PC-independent alarm output Visualisation on PC Software supports English, German, French, Finnish, Dutch and Italian languages

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

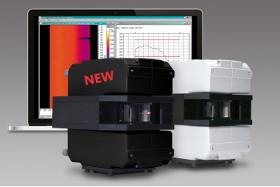

The ThermoView TV30 thermal imaging camera provides a rich feature set of automation and control capabilities along with the expected durability to meet the demanding industrial applications that FPI product need to survive in. TV30 can interface directly to factory automation equipment, 3rd party software such as Labview, or Fluke Process Instruments ThermoView software. By incorporating a built-in I/O for automation applications in a small foot print, you can expand your field of view by providing continuous infrared images, recording, and actionable analytics right at your fingertips. To meet the factory automation needs of today, TV30 cameras utilize edge technology to provide analytics calculations and on board I/O, multiple fieldbus protocol capabilities to interface to a variety of factory automation equipment, along with high-speed GigE vision capability for the most demanding applications.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The IRCON ScanIR3 infrared linescanner provides real-time, thermal imaging of continuous sheet and web-based processes as well as discrete manufacturing processes. The robust housing includes built-in provisions for water-cooling and air-purge, and features built-in laser sighting. A rugged processor box provides universal input and output capabilities in the field without the need for an external computer. The versatile ScanView Pro software allows for custom configuration of operating parameters and display of thermal images and temperature profiles on a standard PC. Features: Fast scan speed up to 150 lines per second Up to 1024 measurement points per line High optical resolution up to 200:1 (allows for installation further from the measured process with excellent precision) Reliable Ethernet communication (optional fiber optics) Brushless scanning motor Field-replaceable window One bundled sensing head cable with one-click connector to the scanner

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Raytek GS150 thermal imaging systems enable automated quality control in glass bending, forming, annealing, and tempering processes. The GS150LE variant is especially designed for Low-E (low emissivity) glass / one-side coated flat glass. It features automatic emissivity correction. The systems are based on the Raytek MP150 infrared line scanner, which has a max. resolution of 1024 points per line, a max. 150 Hz scanning frequency, and an up to 90° wide field of view. SYSTEM PROPERTIES • Automated temperature monitoring • Visualization on PC • Ethernet TCP/IP interface integrated in the line scanning system • PC-independent alarm output • PC-independent analog outputs 3 x 4 – 20mA BENEFITS • Improve profitability and product quality • Reduce set-up time • Detect defects quickly • Automate quality monitoring for ISO9000 • Reduce scrap • Efficiently manage the heat balance in the oven • Automatically adjust the emissivity value when changing glass types or coatings

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Kiln shell temperatures are monitored along the entire length of the kiln. The infrared line-scanning system detects kiln hot spots due to refractory loss, damage, or wear. Data from up to 4 scanners or individual point sensors (optionally used to monitor the burning zone and tire slips) can be seamlessly integrated into one complete thermal image. Detect abnormal operating conditions such as faulty flame position and shape! Optimize and manage kiln maintenance! Extend the operational life of kiln and refractory! Automated kiln and refractory monitoring Visualisation on PC Ethernet TCP/IP interface PC-independent alarm output Analog outputs 3 x 4 – 20mA To ensure reliable operation in even the harshest kiln environments, the MP150 linescanner, which is used in the CS210 thermal imaging system system, is designed with a rugged cast aluminum housing and mounted in a robust stainless-steel enclosure.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

• Real-time thermal imaging, scan speed up to 300 Hz • Up to 1024 measurement points per line • Wide choice of spectral and temperature ranges • High-quality brushless motor (MTBF 40,000 h) • Built-in Ethernet TCP/IP communications • PC independent alarm output • PC independent 4-20 mA interfaces (3 outputs) • I/O module support for up to 10 sectors/zones (PC independent) • Internal Line Laser for accurate alignment • Rugged, waterproof IP65 enclosure • Air purge keeps window free of dirt and condensation • Built-in water cooling for ambient up to 180 °C (356 °F)

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

— Minimize operator intervention with a fully automated and integrated solution — Capture data from inaccessible or dangerous areas to keep your team safe — Monitor sound signature changes in real-time to prevent unscheduled maintenance Visualize the unheard and unseen with the power of acoustic imaging. The SV600 Fixed Acoustic Imager enables users to continuously detect, locate and visualize air and gas leaks or changes in sound signatures before they become costly problems.

Request for a quote

LLA INSTRUMENTS GMBH & CO. KG

Germany

UV-VIS Hyperspectral imaging camera by LLA can be used for measurements in the wavelength range from 350 nm up to 950 nm. Possible applications are colour definition or food sorting tasks.

Request for a quote

LLA INSTRUMENTS GMBH & CO. KG

Germany

Industrial High-Performance hyperspectral camera systems for sorting applications or quality control purposes. LLA's NIR hyperspectral imaging cameras are based on push-broom technology. The working principle is a surface inspection with a maximum penetration depth of 1mm. Within milliseconds, material will be detected and evaluated.

Request for a quoteResults for

Image images - Import exportNumber of results

16 ProductsCountries

Company type

Category

- Measurement - Equipment & Instruments (7)

- Infrared tubes (3)

- Optical measuring equipment (2)

- Acoustic equipment, electric - professional sound-engineering (1)

- Gas detectors (1)

- Heat treatment furnaces (1)

- Measurement and regulation equipment and instruments - temperature (1)

- Surface inspection systems (1)