- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- belt roller

Results for

Belt roller - Import export

GURTEC GMBH

Germany

Hydraulic operated Rotational speed of brush: max. 150 RPM Can be adjusted by hydraulic pump – brush will be lifted to operation position by hydraulic cylinder and keep same pressure against the belt

Request for a quote

GURTEC GMBH

Germany

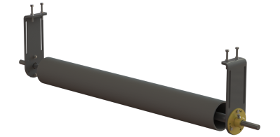

Positive action training frames in all configurations Side guide rollers orientate the frame and help ensure the belt tracks centrally on the conveyor Dimensions: Available in all configurations for both carry and return frames Positive action helps keep the belt aligned with the center of the conveyor

Request for a quote

FORBO SIEGLING GMBH

Germany

Siegling Extremultus live roller belts are energy-saving, durable components of driven live rollers. The quality and performance of the belts determine how quickly and reliably items our customers’ items are distributed. The belt’s tension member plays a key role in this process. Today’s standard is polyester fabric (E). But polyamide sheet (P) or aramide fabric (A) are also used. The tension member is embedded in a thermoplastic intermediate layer. Rubber elastomer or urethane coat the two friction layers, which are the top face of the belt (towards the roller) and the underside of the belt (towards the drive and in some cases to the idler roller). The combination of tension member and coating lends the belt its special characteristics – tailored to conveyor type and purpose. The splice requires no extra adhesives (in the Aramid and Polyester line) and can be made quickly, easily and cleanly on site.

Request for a quote

FORBO SIEGLING GMBH

Germany

Properties • laterally stiff • suitable for knife edges • Belt support: Slider bed (support rollers possible

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Flexible and powerful: the conveyor derinder ASB 600 for artisanal and medium-sized companies with a wide range of applications. The combination machine can be used open with a carriage table or closed with a height-adjustable pressure device and infeed belt. In conveyor operation, all cuts, such as cheek, belly and loin of pork, as well as fat on shoulder and ham are derinded automatically. In open operation, suitable for derinding all round cuts, such as ham, shoulder or knuckle. Advantages Optimal results: clean removal of the rind without residues Infinite adjustment of the rind/cutting thickness Equipped with two operating speeds as standard Compact, movable via fixed and guide rollers Option: Pressure rollers in various hardnesses and air pressing roller Discharge belt Special voltage

Request for a quote

SIGNODE PACKAGING SYSTEMS GMBH - BUSINESS UNIT SMB SCHWEDE MASCHINENBAU

Germany

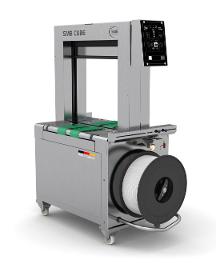

Economical owing to highest availability Robust and extremely low maintenance Easy handling Minimum space requirement Stainless steel configuration ASLF 'Anti-Strap-Loss-Function' Constant strap control Strap width 5 - 12 mm, either DAT 'Direct-Access-Technology' The exclusive eject function avoids strap jam Torque controlled strap tension, adjustable Upstream and downstream interlocks Conveyor speed steplessly adjustable Belt type or roller conveyor Stainless steel welding plate, low maintenance GreenTech energy concept, low power consumption High-Speed-Kit, optional Intuitive operator interface MFT 'Mono-Frame-Technology' Bundle press, optional SAO 'Safe and Open' - Safe without protection doors Bundle flow control Wear-free, energy saving direct-drive-motors Low maintenance and low wear strap arch Many specific options available, easily configurable

Request for a quote

BIZERBA SE & CO. KG

Germany

100 % control of dough in the bakery industry Due to its particularly robust design, the CWPmaxx Bakery checkweigher is ideally suited for use in the hygienically sensitive production environment of the bakery industry. The hygienic design required for this industry is exemplary. The open design facilitates cleaning and minimises product deposits. No or few parts designed to wear a continuous belt, no deflection rollers, and no bearings. A long-lasting drum motor provides reliable propulsion. Optimise your lines' efficiency and increase profits with fill quantity and process control with the CWPmaxx Bakery checkweigher. Normally checkweighing systems can experience hygiene problems due to the overall design. Normally at the point, where in the in feed belt weighing and discharge belts are located. On a normal checkweigher dough will or can drop from the conveyor belt systems and accumulate in the machine. Belts are normally thinner than the conveyor and thus an accumulation can...

Request for a quote

BIAX - SCHMID & WEZEL GMBH

Germany

The unique belt guide system allows the use of very small belt widths without the belt coming off the roller. The tensioning system ensures continual tension in the belt thus contributing to the safety of the guide system. Available in lever or rotary valve variants. Individual work through the rotatable head. Furthermore it has a protective cap for safe handling.

Request for a quote

KB ROLLER TECH KOPIERWALZEN GMBH

Germany

Requirements for products working in a high temperature fusing environment include continuously increasing requests for longer part life, higher print speed, and better print resolution involving ongoing material and process innovations. Our goal is to find the best combination of the following properties: Thermal resistance Thermal conductivity Abrasion resistance Anti-adhesive surfaces Elastomer hardness Substitution of Metal Substrates by Polyimide Belts Fusing by heat and pressure in digital printers has previously been realized with anti-adhesive coatings on aluminum or steel cores. These metal substrates have been increasingly replaced by seamless thin walled polyimide belts due to energy-saving environmental regulations and the growing requirement for “instant on” printing devices. Image Fusing Products Fuser rollers with soft and thin coatings more Fuser rollers for professional digital printing more Pressure rollers with solid silicone/PFA sleeves more Pressure rolle

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The secondary heating system is an integral part of the ContiRoll® and one of the decisive factors for its optimal functioning. For a perfectly dimensioned secondary heating system signicantly contributes to its eciency. The oil is heated in the boiler house to the temperature required and delivered to the primary circuit. The secondary heating station maintains the temperature in the secondary circuit to the press at set temperature by mixing the oil returning from the press that has already cooled down with the hotter oil of the primary circuit. The thermal oil transfers its thermal energy via hot platens, roller rods, steel belts to the mat to be pressed. Features Advancing temperature of the primary circuit is 280 °C Quick-acting aps for immediate re protection Heating circuits for setting the temperature distribution required by the respective process over the entire press length

Request for a quoteSIEMPELKAMP MASCHINENFABRIK GMBH

Germany

When resins containing isocyanate (MDI, PMDI) are used, particles and bres are prone to stick and cake to the steel belts in MDF, OSB and particleboard production. These processes require the use of release agents to be sprayed onto the steel belts. In the press infeed drum seat of the ContiRoll® one unit each is installed at the upper and the lower infeed drums. The release agent application device uses a dip roller to spread the release agent onto the press belts. The surface-textured dip roller rotates inside the release agent tub. The dip roller is pressed against the application roller (setting force is adjustable) to transfer the release agent. The applicator roll applies the agent to the steel belt. Features Precise and economical setting of the agent between 7 and 18 g/m²depending on the product.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

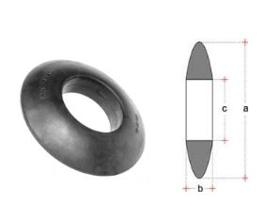

Support rings for type A carrying rollers Type A support rings prevent sap build up and the build up of dirt on the carrying rollers and ensure a straight run in the bottom strand. Support rings (rubber rings) from FTK Förderband Technik Kilian GmbH are attached permanently to the roller and are characterized by their abrasion resistance. In addition to the proven standard, we also manufacture special quality rings such as white food quality rings, oil and grease resistant rings, and rings for extreme temperature ranges ( 40° C to 180° C). Support rings for type B carrying rollers Rollers fitted with type B support rings are used as bottom belt rollers. They are generally placed on the ends of the carrying rollers. Support rings (rubber rings) from FTK Förderband Technik Kilian GmbH are attached permanently to the roller and are characterized by their abrasion resistance.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

FTK Förderband Technik Kilian GmbH has enjoyed renown for belt conveyor hooded covers made of metal for many years. We have decisively extended our product range with the sale and distribution of plastic cover hoods. Due to statutory requirements, different sectors of industry require alternatives to the metal systems. In particular, the industries of food, sugar, chemicals, potash and salt are reliant on hooded covers made of Organit plastic. The corrosion resistant hoods reliably protect conveyor belt, roller bearings and the material conveyed against the weather. They can be easily removed at any location so that the conveyor belt can be inspected and then replaced. Organit conveyor belt hooded covers made of rigid PVC, transparent and natural, in sheeting pile 70/18 have the following features hardly inflammable DIN standard 4102 impact resistant DIN standard 7748 chemically stable DIN standard 16929 maintenance free low weight easy handling

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

Regular rollers prevent belt misalignment and guarantee protection of the belt edges. As the regular rollers only function efficiently when the drum casing is clean, the rollers are equipped and delivered with dirt repellent 60° shore soft rubber. Our regular rollers can be used with both normal and reversing conveyor belts. Mode of operation When the conveyor belt is running straight, the axle through the roller casing forms an angle of 90° to the direction of movement of the belt. When the belt drifts, the roller casing moves, due to the dead weight of the belt, so that a forward motion occurs which brings the belt back to its normal position. The roller casing returns to its normal position as soon as the corrective procedure is completed. The mechanics of the movement are rendered possible due to a complex ball joint in the centre of the roller as well as the position of the axle in relation to the conveyor belt being less than 90°.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The carrying frame prevents belt misalignment and guarantees protection of the belt edges. As the carrying frames only function efficiently when the drum casing is clean, they are equipped and delivered with dirt repellent 60° shore soft rubber. Our carrying frames can be used with both normal and reversing conveyor belts. Mode of operation When the conveyor belt is running straight, the axle through the roller casing forms an angle of 90° to the direction of movement of the belt. When the belt drifts, the roller casing moves, due to the dead weight of the belt, so that a forward motion occurs which brings the belt back to its normal position. The roller casing returns to its normal position as soon as the corrective procedure is completed. The mechanics of the movement are rendered possible due to a complex ball joint in the centre of the roller as well as the position of the axle in relation to the conveyor belt being less than 90°.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DAMBACH LAGERSYSTEME GMBH & CO KG

Germany

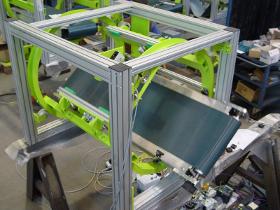

High performance with the new DAMBACH conveyor modules for totes, cartons and trays. With decentralized conveying functions and standardized modules, a wide range of material flows can be mapped easily and quickly. All modules are perfectly matched and can be freely combined. Also thanks to the high level of standardization of individual assemblies. This not only increases flexibility, but also reduces spare parts inventories. The comprehensive container conveyor technology modular system consisting of roller cams, lift converters, infeed and discharge conveyors, accumulating roller conveyors, belt conveyors, lifters and leaves nothing to be desired. Our sales department supports you from the planning phase through layout design to implementation. The robust design with integrated cable ducts and sensors ensures maximum functional reliability. Motor rollers and side guides are easily accessible without time-consuming disassembly of the cover.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

Spiral rings are mounted on standard rollers and used to clean conveyor belts. When the idler roller rotates, the spiral rings move the dirt from the center of the belt outwards through a tumbling motion. The spiral rings (rubber rings) from FTK Förderband Technik Kilian GmbH are permanently fixed on the conveyor roller and are characterized by their abrasion resistant quality. In addition to the tried and tested standard, we also manufacture rings in special quality, e.g. B. white food quality, oil and fat resistant or for the extreme temperature range ( 40 ° C to 180 ° C).

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Oswald Metzen, a METZEN Industries’ brand, is specialised in conveyor technology. We provide you with everything you need under one roof: from planning to production and assembly of our innovative, custom conveyor technology which meets the highest quality requirements. Our conveyor systems portfolio: Screw conveyors Construction of silos, containers and their dispensers Belt conveyors Link conveyors Roller conveyors Rotary tables Bucket lifts Two-shaft shredders Big bag systems Transfer lines/return conveyors with inclined lifts Turning stations Transfer devices Pallet conveyors/changers Interlinking systems Chip conveyors We apply our senior engineers’ expertise in the latest technology and our certified welders’, fitters’, steelworkers’ and electricians’ years of experience to our work in our high-tech manufacturing centres and in your plant. We create in-house or externally designed components and systems. We can step in if you require short-term

Request for a quote

GERMANBELT SYSTEMS GMBH

Germany

Idler with precision roller tube and precision groove ball bearing, multiple labyrinth, dust cover, rain cover and grease chamber Support rings and buffer rings Side guiding rollers Holding brackets for lower belt rollers

Request for a quote

GERMANBELT SYSTEMS GMBH

Germany

Adhesive germanBond® 4kR CFC-free Permanently elastic two-component contact adhesive for conveyor belt splices, conveyor belt repair and conveyor belt pulley lining, particularly for rubber/rubber, rubber/fabric, rubber/metal and fabric/fabric bonding. Applications: such as for cold bonding of rubber conveyor belts (splicing), wear protection linings, conveyor belt pulley and roller or idler laggings. ... more

Request for a quote

GLÄSNER SANDSTRAHL MASCHINENBAU GMBH

Germany

Beam machine for irradiating a glass sheet conveyor belt Transport device supporting roller guide, motor nozzle movement, infinitely variable, attached dust filter system and electronic Control. Max. Lens height for automatically rays 1.200 mm Max. Lens height for manually rays 1.500 mm

Request for a quote

KÖRBER SUPPLY CHAIN AUTOMATION EISENBERG GMBH

Germany

Advantages • Quick throughput times, high processing exactness as well as improved working conditions through optimally planned material flow • Compatible components reduce interfaces • Large assortment of standard components: Belt Conveyors: • Curved Belt Conveyors • Small Belt Conveyors • Inclined Belt conveyors Roller Conveyors: • Wheel Conveyors • Light Roller Conveyors • Roller Conveyor Curves • Gravity Roller Conveyors • Driven Roller Conveyors Chain Conveyors: • Chain Conveyors • Traction Lifts Product transportation is an essential element of in-plant logistics. Exact and precise handling is a prerequisite for optimal material flow. Belt conveyors are ideal for transporting light to moderately heavy products. Roller conveyors can be adapted to a variety of space conditions. They are used for transporting light as well as heavy products, are impervious to dust and thus ideal for use in dusty environments.

PETRI VERPACKUNGSTECHNIK GMBH

Germany

Design features: solid construction Longitudinal sealing Main shaft drive frequency-controlled three-phase drive Paper cutting knife Film removal control Product insertion control intermittent product delivery clocked forehead sealing frameless protective doors made of 15mm Makrolon PLC control Additional devices: Tear-off thread with tip cut Photoelectric print control Marking printing devices Coding (inkjet / laser) two film rolls automatic reel change Brochure and sample inserts external control devices Vibration equalization for granular contents Roller and belt leveler for powdery products Height sensing and ejection station for container completeness control Processing of heat sealable paper Discharge stack and turning device full-surface, double-sided face sealing oversized film roll Servo drives Machine mobile

Request for a quote

PETRI VERPACKUNGSTECHNIK GMBH

Germany

Design features: solid construction Longitudinal sealing rotary foil wrapping head Main shaft drive frequency-controlled three-phase drive Rotary shear cut knife Film removal control Product insertion control continuous product transport through the folding switches continuously working forehead sealing quick format adjustment Protective doors made from Makrolon, relieved of gas pressure springs PLC control Additional devices: Tear-off thread with tip cut Photoelectric print control Marking printing devices Coding (inkjet / laser) two film rolls automatic reel change Brochure and sample inserts external control devices Vibration equalization for granular contents Roller and belt leveler for powdery products Height sensing and ejection station for container completeness control Processing of heat sealable paper Discharge stack and turning device full-surface, double-sided face sealing oversized film roll Servo drives Machine mobile

Request for a quoteResults for

Belt roller - Import exportNumber of results

27 ProductsCountries

Category

- Bearings - ball, needle and roller (4)

- Conveyor belts (2)

- Conveyor systems (2)

- Crate packing machinery (2)

- Rolling machines (2)

- Rubber products (2)

- Wood veneer - machinery and equipment (2)

- Grinding - machine tools (1)

- Measurement - Equipment & Instruments (1)

- Meat processing machines (1)

- Palletising machinery (1)

- Sandblasting equipment (1)

- Steel, crude (1)

- Storage equipment and systems (1)