- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- bearing bushes

Results for

Bearing bushes - Import export

IDG-DICHTUNGSTECHNIK GMBH

Germany

Sealing and bearing of rods, shafts, axes and spindles. Linear, oscillating and helical motion. Liquids, pastes and gases.

Request for a quote

N&H TECHNOLOGY GMBH

Germany

We offer customized die-cast parts, stamped parts, deep-drawn parts, turned parts, milled parts and contact springs, both as small-precision and large parts. Partial or complete plastic and rubber injection molding of metal parts is also part of our portfolio. The manufactured metal parts can be completed with sealing elements, threaded inserts and bearing bushes. We also offer processes for cold pressing, as well as cost-effective surface finishing. We accompany our customers throughout the entire project process and organize the tool and sample production as well as the production (including surface finishing) and optionally also the assembly of the series parts.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

For fast determination of thermally-dependent interruptions in electrical circuits or components Avoidance of heat damage when soldering electrical components For heat protection of neighbouring components Shrinking of inner parts for removal of seized taper plugs, pins, plugs or bearing bushes Generation of shrink seats for assembly of inner parts For rapid temperature adjustment during materials testing For simulation of cold-starting conditions with motor-vehicle automatic starting systems Advantages and benefits Highly effective due to outstanding undercooling effect Excellently suited for simple cooling of parts Immediate cooling of smaller surfaces or parts down to –45°C depending on spraying duration Evaporates very quickly without residues Also provides good cleaning effect No negative affects on plastics and insulating materials

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

In 2015 the product name was changed. The old product name was Castrol Optimol Paste PL. Black assembly paste with MoS2 Description Castrol Molub-Alloy Paste PL (previous product name Castrol Optimol Paste PL) is particularly suitable for pressure-loaded sliding points as well as base and thin film lubrication at high pressures and temperatures. For larger areas and in hard-to-reach places such as bores, threads and sprockets, the use of Castrol Molub-Alloy Paste PL Spray is recommended . Application Castrol Molub-Alloy Paste PL can be used for screw connections, snug and press fits at high temperatures up to +600 °C, on plain bearings, bushings and gears, on drive trains in the automotive industry, for basic lubrication of bed tracks, guides and joints as well as for clean Separation of tool and workpiece during hot forming of metals.

Request for a quote

BIZERBA SE & CO. KG

Germany

Smooth processes and reliable investment protection This high-quality Bizerba lubricant is suitable for all lubrication points which constantly need to be lubricated. Maintain the running and gliding properties of your equipment with this multipurpose product. Area of Use Load receptors Meat and bone saws Mincers Tenderizer / strip cutter Slicers Highlights Suitable for rolling and bush bearings as well as seals Water-resistant and resistant to bacteria, disinfectants and cleaning agents Serves as corrosion protection Effective and economical in use

Request for a quote

MBS-HYDRAULIK GMBH & CO KG

Germany

The MBS hydraulic cylinders of the MZR-1019 series are lightweight cylinders where weight is of crucial importance. They were designed for the areas of mobile hydraulics, crane and aerial work platform construction. All cylinders work with low friction and are characterized by a stick-slip-free run. Lift and piston rod overhang are variable selectable. The cylinder connection is via plain bearing bushes. Connections are provided on the valve plate or a control block, which are flanged to the cylinder via welded pipes, in accordance with DIN EN 280. With the exception of the piston rod, all surfaces are protected against corrosion with a black primer. On request alternative surface treatments are possible. The surface of the piston rod is hard chromed, ground and polished. The cylinders are suitable for hydraulic fluids of types H, HL and HLP according to DIN 51524/51525. If you have questions about areas of application or other options, we are happy to answer them. Download the...

Request for a quote

MBS-HYDRAULIK GMBH & CO KG

Germany

The MBS hydraulic cylinder MZR-1008 is designed as a discharge cylinder of direct support systems on mobile devices, such as Cranes have been constructed. The integrated position measuring system enables the exact position of the support cylinder to be detected. This is hydraulically fixed in connection with the piped double check valve. The cylinder connection is via plain bearing bushes. There are connecting bores for pipe fittings according to BSPP ISO1179-2 in the valve block. Hub and piston rod overhang are variably selectable. With the exception of the piston rod, all surfaces are protected against corrosion with a black primer. On request alternative surface treatments are possible. The surface of the piston rod is hard chromed, ground and polished. The cylinders are suitable for hydraulic fluids of types H, HL and HLP according to DIN 51524/51525. If you have questions about areas of application or other options, we are happy to answer them. Download the data sheet for...

Request for a quote

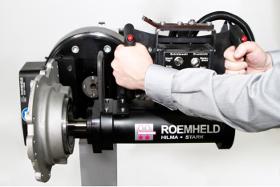

RÖMHELD GMBH FRIEDRICHSHÜTTE

Germany

Hydraulic pull-in device for mounting bearings max. pulling force 100 kN, stroke up to 200 mm, horizontal design Application The bearing press is suitable for the simple mounting of bearings, plain bearings or sleeves/bushings by hydraulically pulling them into the bearing seat. Main areas of application - Industrial assembly workstations - Mounting bearings in housings - Maintenance work - Bearing assembly on large/heavy components Description The bearing press is designed for the hydraulic insertion of bearings into housing components and is available in a horizontal design. Guided on a knuckle boom crane with a balancer (not included in the delivery), the bearing press can be used ergonomically anywhere and can also be mounted on a trolley. The pullin cylinder can be used either from the right or left by converting the hydraulic cylinder. The device is operated by means of a twohand control.

Request for a quote

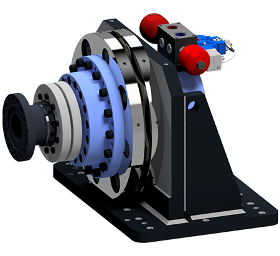

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

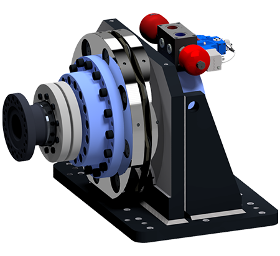

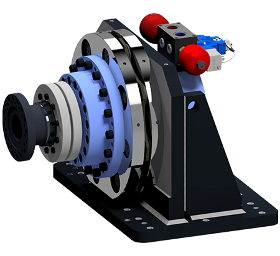

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quote

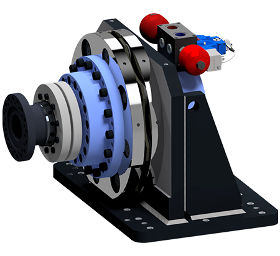

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quote

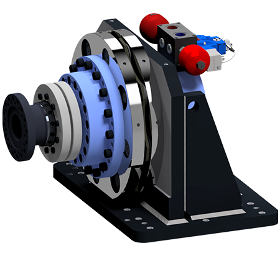

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quote

SYSKOMP GMBH - EMICO

Germany

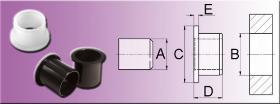

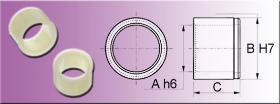

Suitable for all rotating and moving parts. Ideal for silent hinges and low-speed machines. Electrical insulation between shaft and bearing housing. Material: PA 6.6 Colour: natural Item with last digits 599 = dyed black by emico Due to its gliding properties and high wear resistance, polyamide is also very applicable during dry running. Resistant to fouling, atmospheric influences and to the majority of chemicals. After assembly the bearing clearance is approx. 1% of the shaft diameter. Further types or materials on written request.

Request for a quote

SYSKOMP GMBH - EMICO

Germany

Suitable for all rotating and moving parts. Ideal for silent hinges and low-speed machines. Electrical insulation between shaft and bearing housing. Material: PA 6.6 Colour: natural Due to its gliding properties and high wear resistance, polyamide is also very applicable during dry running. Resistant to fouling, atmospheric influences and to the majority of chemicals. After assembly the bearing clearance is approx. 1% of the shaft diameter. Further types or materials on written request.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CL MACHINERY GMBH

Germany

The VK900 bottle capper headset is Closure Systems International's tried-and-tested standard headset for aluminum roll-on closures. A customizable configuration of two flange and two thread rollers ensures optimum sealing efficiency. The head's slim construction makes it suitable for use even on small-pitch machines. Reliable & Simple Fast and simple control of side pressure using easy-access adjuster nuts Exactly coordinated leverages allow very small side pressure All bearings are fitted with replaceable bushings for easy replacement Two variable thread rollers and two adjustable flange rollers ensure uniform lateral forces, enabling the thread to be rolled out with maximized precision Tracer pin (safety plunger) prevents the roller arms engaging if there is no closure present NO LUBRICATION required. No grease point! Maintenance-free ejector reduces stress, extending the maintenance intervals 100% stainless steel Versatility The centering bell to prevent skewed closures is...

KFB CLARFELD GERMANY GMBH

Germany

Axial needle cage assemblies Axial needle cage assemblies, composed of synthetic or metal axial cage assemblies with integrated needle rollers, have an extremely low overall height. They tolerate high axial forces acting in one direction, radial forces must be taken up separately. The deployment of axial needle cage assemblies requires that hardened and bevelled thrust surfaces may be used as raceways. Thrust bearing washers Thrust bearing washers are punched, hardened and polished and can be used as shaft or housing washers. These washers are appropriate when the adjoining machine part when not hardened, is rigid enough and of a stable form. Axial needle bearings Axial needle bearings are components made up of axial needle rollers and cage assemblies and axial washers with centring bore. They can be combined with needle sleeves, needle bushes and needle bearings. The thrust surface for the cage assembly must be hardened and bevelled. The product types AXK and K are applicable here

Request for a quote

IBK WIESEHAHN GMBH

Germany

Technical plastics for industry are a further speciality of IBK. We produce plastic parts to your specifications (ISO, CAD, drawing) for all temperature ranges and with specific chemical resistance. Whether unusual, complex or just simple forms – we turn, inject, saw, drill or mill, whatever you require. We supply semi-finished products as round bars, plates, pipes, rods, profiles or individual cuts, rolls, rollers or wheels with or without coating. Furthermore finished parts, such as protective systems for safety at the workplace in electronic applications. We process all types of plastic, from polyamide to hard PVC through to GRP/FRP. Semi-finished parts: Plates, Blocks, Full rods, Hollow rods, Pipes, Cut pieces Finished parts Cut and processed (turned, milled, drilled etc.) to drawing, sketch or sample, such as - Wheels, Rollers, Bearing bushes, Thrust rings, Bands, Sleeves, Strips

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Bulk handling of any kind in sea and inland ports or storage facilities. For ship-to-ship, ship-to-storage/wagon/silo handling. For various types of crane with control systems designed for hydraulic motor grab systems. Technical design Designed as a discharge and ship unloading grab with retracted pivot bearings for easy gripping under the ship’s gangway Optimisation of crane load capacity thanks to its lightweight design which can hold maximum loads Grab drive: Vertical electrohydraulic drive unit with high-pressure pump Closing and opening movements are controlled through clockwise or counter clockwise rotation of the electric motor (turn control). The electric motor is only switched on whilst the closing and opening movement is being performed. Grab connection bearing: Re-greaseable steel bushing bearing Stable, torsion-resistant design using direct cylinder linkage

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Handling general scrap, steel chips, shredder scrap, wood chippings and much more, in sea and inland ports and at storage facilities. For various types of handling machinery (mobile, stationary, crawler or portal) designed to be connected to hydraulic attachments. Technical design Open, half-closed or closed grip; with 2, 4 or 5 shells Optimisation of machine load capacity thanks to its lightweight design which can hold maximum loads Grab drive: Hydraulic hoses connect the materials handling machine to the grab Closing and opening movements are controlled by the materials handling machine Closing and opening movements controlled by directly connected hydraulic cylinders Grab connection bearing Re-greaseable, robust steel bushing bearing Stable, torsion-resistant shells made of: Shell plates made of S355J2+N Welded shell tips made of special highly wear-resistant steel

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Bulk handling of any kind in sea and inland ports or storage facilities. For ship-to-ship, ship-to-storage/wagon/silo handling. For various types of handling machinery (mobile, stationary, crawler or portal) designed to be connected to hydraulic attachments. Technical design Half-closed or closed grip; with 2 or 4 cylinders Optimisation of machine load capacity thanks to its lightweight design which can hold maximum loads Grab drive: Hydraulic hoses connect the materials handling machine to the grab Closing and opening movements are controlled by the materials handling machine Closing and opening movements controlled by directly connected hydraulic cylinders Grab connection bearing Re-greaseable, robust steel bushing bearing Stable, torsion-resistant shells adapted to material flow: Shell plates made of S355J2+N Cutting edges made of special, highly wear-resistant steel

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Slag handling in waste incineration plants or incineration plants of any kind. For various types of cranes with internal or external holding cables. Technical design Designed as a discharge grab with stable, retracted pivot bearings Optimisation of crane load capacity thanks to its lightweight design which can hold maximum loads Self-locking grab suspension for crane hooks Grab drive: Vertical electrohydraulic drive unit with high-pressure pump Closing and opening movements are controlled through clockwise or counter clockwise rotation of the electric motor (turn control). The electric motor is only switched on whilst the closing and opening movement is being performed. Closing and opening movements controlled by directly connected hydraulic cylinders, with stable piston rod protection Grab connection bearing Re-greaseable, robust steel bushing bearing KRÖGER MAINTENANCE-FREE bearing system Grab shells: Shell design adapted to material flow Toothed segment drive Material: S355J2+N

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Waste incineration plants, refuse-derived fuel (RDF) incineration plants or incineration plants of any kind. For various types of cranes which operate using hooks or rope/chain suspension. Technical design Open shell design Suitable for handling all kinds of waste Optimisation of crane load capacity thanks to its lightweight design which can hold maximum loads Self-locking grab suspension for crane hooks Grab drive: Vertical electrohydraulic drive unit with high-pressure pump Closing and opening movements are controlled through clockwise or counter clockwise rotation of the electric motor (turn control). The electric motor is only switched on whilst the closing and opening movement is being performed. Closing and opening movements controlled by directly connected hydraulic cylinders, with stable piston rod protection Grab connection bearing: Re-greaseable, robust steel bushing bearing KRÖGER MAINTENANCE-FREE bearing system Stable shell structure with shells made out of S355J2+N

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Bulk handling of any kind in sea and inland ports or storage facilities. The compact alternative to the MZG type grab for ship-to-ship, ship-to-storage/wagon/silo handling. For various types of crane with control systems designed for hydraulic motor grab systems. Technical design Designed as a discharge and ship unloading grab with retracted pivot bearings for easy grab under the ship’s gangway Optimisation of crane load capacity thanks to its lightweight design which can hold maximum loads Self-locking grab suspension for crane hooks Grab drive: Horizontal electrohydraulic drive unit with high-pressure pump Closing and opening movements are controlled through clockwise or counter clockwise rotation of the electric motor (turn control). The electric motor is only switched on whilst the closing and opening movement is being performed. Grab shells: Material: S355J2+N Grab connection bearing: re-greaseable, robust steel bushing bearing Small grab dimensions thanks

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Waste incineration plants, refuse-derived fuel (RDF) incineration plants or incineration plants of any kind. For various types of cranes with internal or external holding ropes. Technical design Low-maintenance or maintenance-free for increased profitability 4-rope grab with half-closed grip Suitable for handling waste of any kind Closing rope devices: Rope nozzles KROGER MAINTENANCE-FREE, rope-protecting, roller-bearing pulley system Rigidly mounted main casing to accommodate the lower rope pulleys, easily move the ropes and reduce wear on them even when the crosshead is at an angle whilst the grab is being operated Solid, removable rope guards Rope pulley bearing: Re-greaseable plain bearing KROGER MAINTENANCE-FREE pulley block system Grab connection bearing: Re-greaseable steel bushing bearing KROGER MAINTENANCE-FREE bearing system Stable shell structure with shells made out of S355J2+N with a wear-resistant edge recessing made of Pantanax steel

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Slag handling in waste incineration plants or incineration plants of any kind. For various types of cranes with internal or external holding ropes. Technical design Low-maintenance or maintenance-free for increased profitability Transverse or longitudinal suspension with 4-fold, 5-fold and 7-fold rope reeving; as a 4-rope grab High load capacity thanks to its lightweight design Smooth grab thanks to its low centre of gravity and because the rope’s diameter matches that of the pulley Closing rope devices: Rope nozzles KROGER MAINTENANCE-FREE, rope-protecting, roller-bearing pulley system Lower pulley block unrestrained on the crossbeam Rope pulley bearing: Re-greaseable plain bearing KROGER MAINTENANCE-FREE pulley block system Grab shells: Material: S355J2+N Cutting edge material: special, highly wear-resistant steel Grab connection bearing: Re-greaseable steel bushing bearing KRÖGER MAINTENANCE-FREE bearing system

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Handling general scrap, car bodies, steel chips, shredder scrap, paving stones and much more, in sea and inland ports. For pier engineering and riverbed maintenance. For various types of cranes and excavators with internal or external holding ropes. Technical design As 2-rope and 4-rope grabs with open, half-closed or closed grip Suitable for handling scrap, stones, waste and other difficult to grab goods depending on design Closing rope devices: Rope nozzles KRÖGER MAINTENANCE-FREE, rope-protecting, roller-bearing pulley system Rigidly mounted main casing to accommodate the lower rope pulleys, easily move the ropes and reduce wear on them even when the crosshead is at an angle whilst the grab is being operated Rope pulley bearing: Re-greaseable plain bearing KRÖGER MAINTENANCE-FREE pulley block system Grab connection bearing: Re-greaseable steel bushing bearing KRÖGER MAINTENANCE-FREE bearing system Stable shell structure with shells made out of S355J2+N.

Request for a quoteResults for

Bearing bushes - Import exportNumber of results

32 ProductsCountries

Company type

Category

- Hydraulic equipment (9)

- Electric motors and parts (7)

- Lubricants, industrial (1)

- Electrical and magnetic insulation (1)

- Greases, crude (1)

- Metallurgy and iron and steel industry - machinery and installations (1)

- Plastics - industrial products (1)

- Precision engineering hand tools, non-power (1)

- SMALL METAL PARTS (1)

- Sealing rings (1)

- Silicones (1)