- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- bath products

Results for

Bath products - Import export

SCHÖPP-SPORTBODEN GMBH

Germany

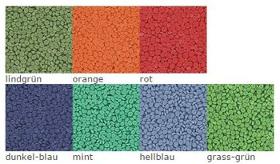

The sliding surfaces used in the past had a number of weak points, which can be attributed to the granules used: Quartz sand is too hard and destroys the base coverings very quickly, while the various rubber granules are too soft and too uneven in shape, so that they in turn are ground up relatively quickly. Both sliding media are controversial due to the dust they generate and bring with them unpleasant side effects such as breathing difficulties, discolouration of clothing and a great deal of cleaning work in the tennis hall and social areas. A new manufacturing process has made significant progress possible: Perfect-Glide tennis granules are not ground from a block of rubber like conventional granules, but are spun into threads using an extruder and then cut to a defined length in a cooling bath. This process enables the production of fine, dust-free extruder micro-granules in a new, optimised lens shape.

Request for a quote

RCP RANSTADT GMBH

Germany

We not only fill the materials provided by our customers. We also have modern equipment and extensive know-how to manufacture your fillings for you according to your formulae. For this purpose, a variety of powder mixers for manufacturing the following products is available: Dietary supplements Powdered drinks Bath salts / bath pearls Detergents and cleaning products In addition, we have several liquid mixers, which can be used, for example, for Alcohol / water-based solutions Food pastes and gels Detergents and cleaning products For the manufacturing of creams, emulsions and lotions for high-quality cosmetics, we work together with specialist partners.

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal installation – suitable for vertical CNC-controlled milling machines -For automation of machining centres – particularly suitable for batch production -The hydraulic spindle also enables the use of support jaws with which a wide range of unmachined parts, from flame-cut and sawn materials through to complex castings, can be clamped securely and economically. Suitable for materials with a strength of up to approx. 1000 N/mm². Product features: -Extreme accuracy for your machining -The clamping force is generated via the pressure from a hydraulic unit with a hydraulic clamping stroke of up to 4.5 mm -The clamping force is steplessly adjusted by regulating the hydraulic pressure on the hydraulic unit. A hand crank is provided for coarse adjustment of the clamping range -The spindle contains a single-acting hydraulic piston and an additional Belleville spring assembly

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal installation – suitable for vertical CNC-controlled milling machines -For automation of machining centres – particularly suitable for batch production Product features: -Extreme accuracy for your machining -The clamping force is generated via the pressure from a hydraulic unit with a hydraulic clamping stroke of up to 4.5 mm -The clamping force is steplessly adjusted by regulating the hydraulic pressure on the hydraulic unit. A hand crank is provided for coarse adjustment of the clamping range -The spindle contains a single-acting hydraulic piston and an additional Belleville spring assembly

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Bath products - Import exportNumber of results

4 ProductsCountries

Company type