- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- bar steel

Results for

Bar steel - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These parts are used for printer accessories.

Request for a quote

ROLLON GMBH

Germany

The ECO SYSTEM units are linear actuators made of a self-sustaining extruded aluminum frame and are driven by a polyurethane belt with AT metric profile steel inserts. Three different sizes available: 60mm, 80mm, 100mm Version available with recirculating ball bearing or roller rails Reduced weight ensured by the light frame and the aluminum sliders High sliding speed The ECO SYSTEM series actuators are offered with two motion systems: ECO SYSTEM – SP Featuring a maintenance free recirculating linear guide rail fitted inside the profile. ECO SYSTEM – CI Featuring four rollers with a Gothic arch outer profile sliding on hardened steel bars placed inside the profile. Main fields of application for Eco System linear units: Automation Packaging Industrial machinery

Request for a quote

KEBA FASTENINGS

Germany

PRODUCTION CAPABILITIES KEBA Fastenings’ processing capacity for Turned-Parts comprised of steel, brass, aluminum, and stainless steel bars ranges between Ø 1mm to Ø 60mm via CNC Auto Lathe, Index, and Sliding Automat machinery. The manufacturing technology and team capabilities allow for custom made parts according to customer-specific drawings. SURFACE TREATMENT • Browning • Anodised • KTL • Zinc - Lamella • Galvanized (blue, yellow, black) • Zinc - Iron • Zinc - Nickle Powder • Phosphating • Chrome • Copper

Request for a quote

C+R HYDRAULICS GMBH

Germany

• flat steel • wide flat steel • strip steel • round steel • square steel • t-steel • u-steel • angled steel isoceles • angled steel non-isoceles

Request for a quote

HAAG + ZEISSLER MASCHINENELEMENTE GMBH

Germany

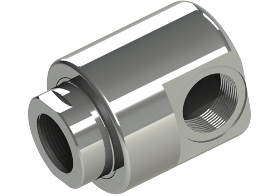

steel (42CrMo4) or stainless steel (1.4571) PTFECompoundseal builtin ball guiding track similar to ball bearings swiveling, rotating movements with low speed PRESSURE MAXIMUM 40 bar Stainless steel 100 bar Steel 42CrMo4 SIZEDN 20 (3/4") DN 25 (1") DN 32 (1 1/4") DN 40 (1 1/2") DN 50 (2") DN 65 (2 1/2") DN 80 (3") DN 100 (4")

Request for a quote

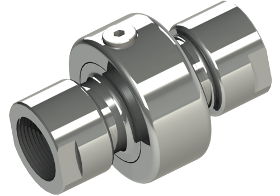

HAAG + ZEISSLER MASCHINENELEMENTE GMBH

Germany

steel (42CrMo4) or stainless steel (1.4571) PTFECompoundseal builtin ball guiding track similar to ball bearings swiveling, rotating movements with low speed PRESSURE MAXIMUM 40 bar Stainless steel 100 bar Steel 42CrMo4 SIZEDN 8 (1/4") DN 10 (3/8") DN 15 (1/2") DN 20 (3/4") DN 25 (1") DN 32 (1 1/4") DN 40 (1 1/2") DN 50 (2")

Request for a quote

HAAG + ZEISSLER MASCHINENELEMENTE GMBH

Germany

brass or stainless steel Vitonseal (FEP optional) builtin ball guiding tracks similar to ball bearings swiveling, rotating movements with low speed for simple applications for example hose reels PRESSURE MAXIMUM PRESSURE MAXIMUM 16 bar Stainless steel Brass PRESSURE MAXIMUM 16 bar Stainless steel Brass

Request for a quote

C+R HYDRAULICS GMBH

Germany

Cold-rolled (2B/IIIc) and hot-rolled (1D/IIa) in the following versions: • foil-coated • ground • brushed • bright annealed (2R/IIId) in den formats: • small format 1.000 x 2.000 mm • medium format 1.250 x 2.500 mm • large format 1.500 x 3.000 mm • as well as custom dimensions upon request Stainless steel pipes and steel bars upon request

Request for a quote

HAAG + ZEISSLER MASCHINENELEMENTE GMBH

Germany

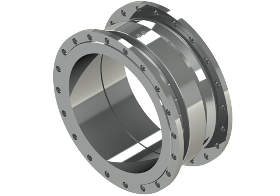

steel (42CrMo4) or stainless steel (1.4571) PTFECompoundseal builtin ball guiding tracks similar to ball bearings swiveling, rotating movements with low speed PRESSURE MAXIMUM Steel 42CrMo4 16 bar DN 350 DN 400 DN 500 DN 600 DN 700 40 bar DN 125 (5") DN 150 (6") DN 200 (8") DN 250 (10") DN 300 (12") Stainless steel 6 bar DN 350 DN 400 DN 500 DN 600 DN 700 16 bar DN 125 (5") DN 200 (8") DN 250 (10") DN 300 (12") SIZEDN 125 (5") DN 150 (6") DN 200 (8") DN 250 (10") DN 300 (12") DN 350 DN 400 DN 500 DN 600 DN 700

Request for a quote

HAAG + ZEISSLER MASCHINENELEMENTE GMBH

Germany

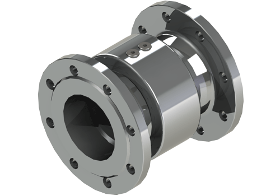

steel (42CrMo4) or stainless steel (1.4571) PTFECompoundseal builtin ball guiding tracks similar to ball bearings swiveling, rotating movements with low speed PRESSURE MAXIMUM Steel 42CrMo4 100 bar DN 150 (6") DN 200 (8") DN 250 (10") DN 300 (12") 250 bar DN 65 (2 1/2") DN 80 (3") DN 100 (4") DN 125 (5") 350 bar DN 20 (3/4") DN 25 (1") DN 32 (1 1/4") DN 40 (1 1/2") DN 50 (2") Stainless steel 40 bar DN 150 (6") DN 200 (8") DN 250 (10") DN 300 (12") 100 bar DN 20 (3/4") DN 25 (1") DN 32 (1 1/4") DN 40 (1 1/2") DN 50 (2") DN 65 (2 1/2") DN 80 (3") DN 100 (4") DN 125 (5") SIZEDN 20 (3/4") DN 25 (1") DN 32 (1 1/4") DN 40 (1 1/2") DN 50 (2") DN 65 (2 1/2") DN 80 (3") DN 100 (4") DN 125 (5") DN 150 (6") DN 200 (8") DN 250 (10") DN 300 (12")

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

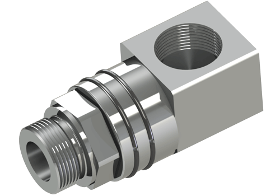

HAAG + ZEISSLER MASCHINENELEMENTE GMBH

Germany

steel (42CrMo4) or stainless steel (1.4571) PTFECompoundseal builtin ball guiding tracks similar to ball bearings swiveling, rotating movements with low speed PRESSURE MAXIMUM Steel 42CrMo4 315 bar DN 32 (1 1/4") DN 40 (1 1/2") 350 bar DN 8 (1/4") DN 10 (3/8") DN 15 (1/2") DN 20 (3/4") DN 25 (1") Stainless steel 100 bar DN 32 (1 1/4") DN 40 (1 1/2") 160 bar DN 8 (1/4") DN 10 (3/8") DN 15 (1/2") DN 20 (3/4") DN 25 (1") PRESSURE MAXIMUM Steel 42CrMo4 315 bar DN 32 (1 1/4") DN 40 (1 1/2") 350 bar DN 8 (1/4") DN 10 (3/8") DN 15 (1/2") DN 20 (3/4") DN 25 (1") Stainless steel 100 bar DN 32 (1 1/4") DN 40 (1 1/2") 160 bar DN 8 (1/4") DN 10 (3/8") DN 15 (1/2") DN 20 (3/4") DN 25 (1")

Request for a quote

SPANSET SECUTEX GMBH

Germany

Wipers for steel bars In the production of pipes and steel bars, socalled wipers are used for leaning. The wipers have a round or rectangular outer profile and an inner profile that matches the shape of the object to be cleaned. Normally, several wipers are mounted in series, whereby the passthrough openings are smaller than the profile. The bar is pushed through the elastomer plates at high velocity, and the rubbery material strips the surface free from grease and cleaning fluid residues. It is the edge that counts! Just a like a car window wiper, it is the edge that counts. Normally, the wipers are stamped from sheet goods. During stamping, the elastomer becomes distorted; the inner edge is therefore not dimensionally stable and is at an angle. Only part of the edge wipes emulsions from the surfaces depends on the profiles. This edge is rapidly worn down; the cleaning action is then unsatisfactory. Streakfree cleaning

Request for a quote

MEBA STEEL & INDUSTRIAL SUPPLIES TRADE GMBH

Germany

STEEL GRADES The standrard stock of chromed bars consists of steel grades C45 or C45E or C45R and 20MnV6 in untreated delivery condition (+AR) and 42CrMo4 in quenched and temperd delivery condition (+QT). DELIVERY CONDITIONS The solid bars subjected to chroming process are available in different delivery conditions in orde to obtain specific properties. NORMALIZATION Heat treatment consisting heating process followed by gradual cooling in controlled atmosphere. Thanks to this process the steel structure becomes more "refined" and improve its impact properties (perlitic structure). INDUCTION HARDENING The surface of the steel bar is heated by electric induction followed by fast cooling. This process leads to a high surface hardness but also to fragility and low impact values (Martensite surface structure). QUENCHING AND TEMPERING Quenching process followed by tempering. This process leads to a good hardness and resistance and it reduces its fragility in comparsion to induction...

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

With its sites in Hamm, Schwerte and Zweibrücken/Ixheim, the Westfälische Drahtindustrie bright steel division is one of the most important bright steel manufacturers in the world.The company has a recognised high level of expertise in the field of bar steel production.

Request for a quote

BDSENSORS GMBH

Germany

Features: — nominal pressure: 0 ... 100 mbar up to 0 ... 6 bar — accuracy: 0.5 % FSO — stainless steel sensor without media isolation

Request for a quote

BDSENSORS GMBH

Germany

The battery-powered BAROLI 02 enables a local displaying of values, satisfying the highest demands for accuracy and long-term stability. The pressure gauge may be applied compatible with the stainless steel used; it shows an excellent robustness and a high overpressure protection. The BAROLI 02 display housing is rotatable, thus ensuring an easy reading even under unfavorable mounting conditions. Additional functions: changing the unit, displaying min / max values, calibrating of offset and the span, configuring the automatic switching-off. Features: — nominal pressure: 0 ... 100 mbar up to 0 ... 600 bar — accuracy: 0.125 % FSO — stainless steel diaphragm — 2-line LC display, 4.5-digit 7-segment display, 6-digit 14-segment additional Display — mechanical connections: inch, NPT threads Optional Features: — min- / max-function with reset function — offset and end point calibration — setting the pressure unit

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The dynamic way of sawing The HBE Dynamic series brings many features, which make your production even more profitable: — Solid and durable construction made of vibration damping grey cast iron — Sensitive BEHRINGER downfeed control system — Precise guiding system in portal design — Energy-efficient drive system — Excellent accessibility — Electrically driven chip brush, synchronized with blade speed — Easy operation by intuitive NC control system Different models based on cutting range ( 90° flat / 90° round): — HBE261A Dynamic: 300 x 260 mm / 260 mm — HBE321A Dynamic: 350 x 320 mm / 320 mm — HBE411A Dynamic: 510 x 410 mm / 410 mm — HBE511A Dynamic: 510 x 510 mm / 510 mm

Request for a quote

SCHAKE GMBH

Germany

Head for formwork prop: can be fitted on top of formwork props to hold the wood formwork support for which 4 corner angles are welded Tripod stand: the formwork prop can be fixed simply by a bracket that is supported movably on the tripod stand Formwork clamp: large size for stepless fixing by wedge. Eccentric clamp: for tensioning wire from 5 mm - 10 mm, load up to 2.500 kg Formwork clamp: made of 8 mm thick bent flat-bar steel. Wing nut WOF 27, casting, preferred use for grid-pattern formwork etc.

Request for a quote

PH-CLEANTEC GMBH

Germany

Mobile. Parts cleaning collector with sturdy drip-off grid, 80 kg load capacity, 30l. Water recycling via special sedimentation system with filter monitoring. 60 l water tank, 5 l cleaning agent reservoir, stepless adjustable pressure, metering device for cleaning agent, water shortage control, overheat fuse. Volume 2,8 l /m. 15 KW, 32A. With closed parts cleaning cabin in stainless steel, incl. vapour exhaust system, integrated light and compressed air supply. Access via brush curtains. 5 m hose with large pistol, hand screw coupling and lance SR-LA 600, 1 m hose with small pistol, quick change coupling and nozzle SR-ST inside cabin. Hoses with quick change couplings at the device.

Request for a quote

PH-CLEANTEC GMBH

Germany

Mobile. Parts cleaning collector with sturdy drip-off grid, 80 kg load capacity, 30l. Water recycling via special sedimentation system with filter monitoring. 60 l water tank, 5 l cleaning agent reservoir, stepless adjustable pressure, metering device for cleaning agent, water shortage control, overheat fuse. Volume 1,8 l /m. 10 KW, 16A. With closed parts cleaning cabin in stainless steel, incl. vapour exhaust system, integrated light and compressed air supply. Access via brush curtains. 5 m hose with large pistol, hand screw coupling and lance SR-LA 600, 1 m hose with small pistol, quick change coupling and nozzle SR-ST inside cabin. Hoses with quick change couplings at the device.

Request for a quote

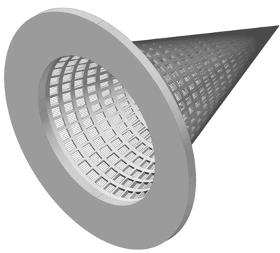

THIELMANN ENERGIETECHNIK GMBH

Germany

CHARACTERISTICS For clamp mounting into the pipeline Efficient protection of dirt-sensitive system components during commissioning Low differential pressure Easy installation and replacement Material Certificates DIN EN 10204/3.1 for Clamp Collar OPTIONS For DIN and ASME flange connections Design for low temperature down to -50 ° C Design pressure up to 100 bar Stainless steel construction Reverse flow direction GENERAL The starting screen VAS is used for commissioning and starting a system in order to clean gas from coarse soiling such as welding bead, scale, grease, etc. After starting, the starting screen can be removed from the pipeline. The design is carried out as a welding design. FUNCTION The starting screen VAS consists of a supporting basket made of perforated sheet metal with a welded clamping ring. These are galvanized after assembly. On the outside of the support basket a stainless steel wire mesh is welded.

Request for a quoteResults for

Bar steel - Import exportNumber of results

29 ProductsCountries

Company type

Category

- Electric motors and parts (6)

- Vacuum cleaners, domestic (2)

- Concrete forms (1)

- Fasteners, metal (1)

- Internal transport systems (1)

- Manometers (1)

- Measurement and regulation equipment and instruments - pressure (1)

- Sawing machine tools (1)

- Steel & Metal Transformation (1)

- Testing equipment (1)

- Windscreen wipers (1)

- Wires and cables, steel (1)