- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- axial bearings

Results for

Axial bearings - Import export

IGUS® GMBH

Germany

Thrust bearing / Spherical axial bearings from igus d1 [mm]: Mechanical properties The self-aligning spherical igubal ® thrust bearings are very easy-to-mount units, which help to compensate for errors and prevent misalignments. The thrust bearing housing pad is made of the impact-resistant, stiff, thermoplastic composite material igumid G. The standard thrust bearing washer is made of iglidur® W300. This combination provides particularly good gliding and wear properties in relative movements. Loads The load carrying capacity of the spherical igubal® thrust bearing is very high in normal ambient temperature. In particular cases the load carrying capacity of the axial bearings should be checked in a practical trial with high constant loads and at higher temperatures. Coefficients of surface friction and speeds Taking the radial loads into account, maximum surface speeds up to 0.5 m/s rotating can be attained. Installation The axial bearing pad is mounted flush and secured. The spherical washer glides loosely in the pad and is held by the shouldered shaft mounted on it. Delivery program As standard, the spherical igubal® axial bearings are supplied in sizes of 5 to 20 mm. For other dimensions, please contact us. Special features Simple assembly Compensation of misalignments Compensation of edge loads Very good gliding and wear properties, low installation space When to use it? When you want to save weight When freedom from corrosion is required When a bearing with good friction coefficients is sought When not to use? When very heavy loads act When constant temperatures of more than +80℃ occur When high rotary speeds must be implemented. Thrust bearing / Spherical axial bearings from igus d1 [mm]:

Request for a quote

IGUS® GMBH

Germany

iglidur® JATM, metric d1 [mm]: iglidur® JATM/VATM consists of a hard-anodized ring and a bearing ring made of iglidur® J (JATM) and iglidur® V400 (VATM). These glide pairings fetch low coefficients of friction and high wear resistance - without lubrication. Special features Maintenance-free plain bearing system For high service performances High stiffening Simple installation Material: iglidur® J High temperature options VATM, iglidur® V400 More dimensions and supplies on request When to use it? When an axial bearing system with defined gliding partners is desired When extremely high wear resistance is required When a very low coefficient of friction is desired When not to use it? When an additional angle compensation is required igubal® axial bearing When little mounting space is available iglidur® J When only sporadic movements are present iglidur® G Y = wear [μm/km] Figure 36.1: The diagram shows the influence of load (p in MPa) and speed (v in m/s) on the wear of the axial bearing. Y= Coefficient of friction Figure 36.2: In the test with different speeds (v) and loads (p) the coefficients of friction of the bearing systems were determined (v in m/s, p in MPa). iglidur® JATM, metric d1 [mm]:

Request for a quote

IGUS® GMBH

Germany

Special features Standard product range from stock radially and axially pre-tensioned plain bearings Completely free of clearance in unloaded state Material: iglidur® J Maintenance-free and calculable service life iglidur® JVSM, metric d1: iglidur® JVSI, inch d1 [inch]: iglidur® JVFM/JVFI Clearance-free pretensioned bearing, fully clearance-free in unloaded state, material: iglidur® J, maintenance-free and predictable service life iglidur® JVFM/JVFI Special features Standard product range from stock radially and axially pre-tensioned plain bearings Completely free of clearance in unloaded state Material: iglidur® J Maintenance-free and calculable service life When to use it? When a radial and/or axial pretension of bearings is desired When a derattling of the bearing in the unloaded state is required When a clearance-free feel is required When not to use it? When a bearing version with reduced clearance is needed Please contact us When the pretension has to withstand high radial forces When absolute clearance-free feature is required at high loads iglidur® JVSM, metric d1: iglidur® JVSI, inch d1 [inch]: iglidur® JVFM/JVFI Clearance-free pretensioned bearing, fully clearance-free in unloaded state, material: iglidur® J, maintenance-free and predictable service life iglidur® JVFM/JVFI

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Material Schulz Stanztechnik manufacturers these axial ball bearings using the materials suited to the specific application. For the housing, steel, brass or stainless steel are used; for rings, steel or stainless steel which is always hardened. The balls are made of chrome or stainless steel, which is also always hardened. All material combinations – depending on their conditions of use – are possible for the assembly of the individual parts. Various surface coats for the individual parts can be supplied as well as finished bearings: brass which is uncoated or nickel plated; steel and stainless steel which is uncoated, zinc plated or nickel plated. All bearings are available lubricated or unlubricated. Structure DLG100 axial ball bearings consist of sheet metal housing, two hardened rings as well as hardened precision balls. Due to their structure, we refer to them as an encapsulated, full ball design.

Request for a quote

RALF LANG MASCHINENBAU GMBH

Germany

Axial bearing 1000 N press, locking ring assembly and testing station

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

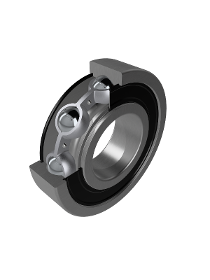

KIS deep groove ball bearings are characterised by their high load carrying capacity and speed stability. Depending on the requirements of your application, they are available in different variants and in both radial and axial design. Our single row deep groove ball bearings are available in open and sealed designs. Open bearings are maintenance-free, while sealed bearings offer better corrosion protection. Single row deep groove ball bearings can support both radial and axial forces. Our double row deep groove ball bearings feature a higher radial load carrying capacity. They are used when the radial load carrying capacity of single row deep groove ball bearings is not sufficient. Axial deep groove ball bearings are suitable for supporting particularly high axial loads. They are available in both single and double direction. Single direction thrust ball bearings can only support axial forces, while double direction thrust ball bearings can support both radial and axial forces.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

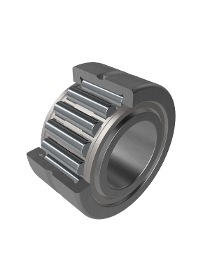

KIS needle roller bearings are ideal for applications that require space-saving rolling bearings with high load carrying capacity. We offer needle roller bearings in both radial and axial designs as well as in combined designs. In bearing technology, cylindrical rolling elements are referred to as needles if the rolling element diameter is ≦ 6 mm and the ratio of rolling element diameter to rolling element length gives a value Dw/lw < 1:3. Radial needle roller bearings are intended exclusively for use as non-locating bearings. The given axial displacement path for bearings with an inner ring allows axial movements between the shaft and the housing. If necessary, wider inner rings are available to allow larger axial displacement paths. Our combined needle bearings are characterised by particularly high precision and efficiency. By integrating both bearings into one unit, combined needle roller bearings are often easier to press in and easier to handle than individual solutions.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

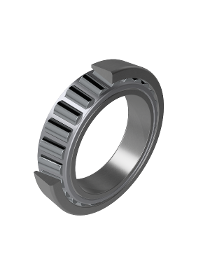

We manufacture our KIS tapered roller bearings in both single and double row designs. Since they can support both axial and radial forces, they can also withstand high loads. Due to their high precision they are suitable for shafts that are to be guided axially precisely (locating bearings) or if the bearing Tapered roller bearings are easy to adjust and disassemble, making them easy to mount and maintain. Tapered roller bearings are the perfect choice for applications where high loads or high precision are required. Our KIS tapered roller bearings are used in a wide range of applications, such as motors, compressors, construction machinery, machine tools and gearboxes. We will be happy to advise you on possible variants with different properties.

Request for a quote

LUTZ PUMPEN GMBH

Germany

The TMR series is a reliable magnetic drive pump that easily handles critical operating conditions due to its patented magnetic axial thrust compensation. * Drive via magnetic coupling with patented magnetic axial thrust compensation * Typical applications: Acids, alkalis, acid and alkali mixtures, solvents, alkaline degreasing baths, electroplating baths, photographic chemicals Features & Advantages * Variable connection options * Compact dimensions, performance in line with requirements * Also for liquids with high density * Due to "magnetic axial thrust balancing" the bearing system "R" is suitable for dry running * Motor and pump are mechanically separated * Connections with thread or flange

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

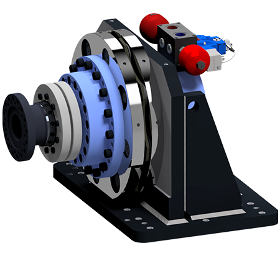

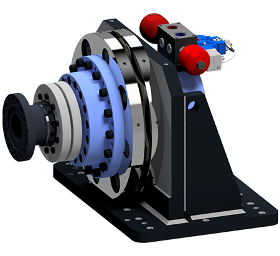

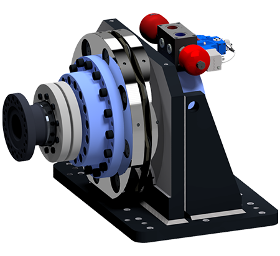

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

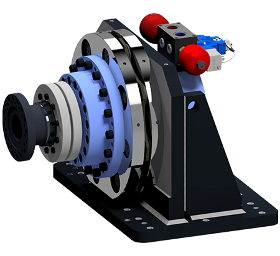

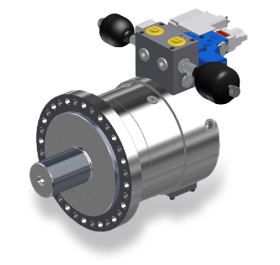

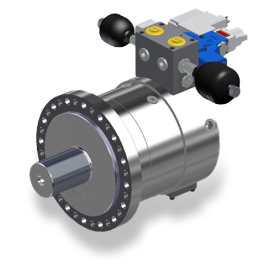

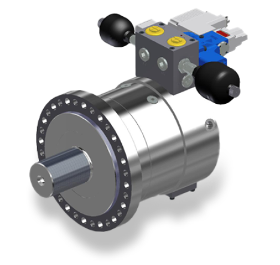

The output shaft of the HSH swivel motors has radial and axial hydrostatic bearings. Here, radially and axially arranged bearing pockets are supplied with pressurized oil via a separate pressure connection. As a result, the output shaft is centered radially and axially between liquid cushions and all metallic contact surfaces are permanently separated from each other by a thin liquid film. This eliminates wear caused by metallic friction in any operating state, even at zero speed compared to hydrodynamic plain bearings. In conjunction with highly dynamic control valves and angle of rotation sensors, these actuators are preferably used in controlled systems in which disturbance variables such as friction and the stick-slip effect must be reduced to a minimum. Furthermore, due to the lack of internal seals, they are ideal for test series with large numbers of load cycles where an interruption, e.g. due to the replacement of internal seals, is not permitted.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The output shaft of the HSH swivel motors has radial and axial hydrostatic bearings. Here, radially and axially arranged bearing pockets are supplied with pressurized oil via a separate pressure connection. As a result, the output shaft is centered radially and axially between liquid cushions and all metallic contact surfaces are permanently separated from each other by a thin liquid film. This eliminates wear caused by metallic friction in any operating state, even at zero speed compared to hydrodynamic plain bearings. In conjunction with highly dynamic control valves and angle of rotation sensors, these actuators are preferably used in controlled systems in which disturbance variables such as friction and the stick-slip effect must be reduced to a minimum. Furthermore, due to the lack of internal seals, they are ideal for test series with large numbers of load cycles where an interruption, e.g. due to the replacement of internal seals, is not permitted.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The output shaft of the HSH swivel motors has radial and axial hydrostatic bearings. Here, radially and axially arranged bearing pockets are supplied with pressurized oil via a separate pressure connection. As a result, the output shaft is centered radially and axially between liquid cushions and all metallic contact surfaces are permanently separated from each other by a thin liquid film. This eliminates wear caused by metallic friction in any operating state, even at zero speed compared to hydrodynamic plain bearings. In conjunction with highly dynamic control valves and angle of rotation sensors, these actuators are preferably used in controlled systems in which disturbance variables such as friction and the stick-slip effect must be reduced to a minimum. Furthermore, due to the lack of internal seals, they are ideal for test series with large numbers of load cycles where an interruption, e.g. due to the replacement of internal seals, is not permitted.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The output shaft of the HSH swivel motors has radial and axial hydrostatic bearings. Here, radially and axially arranged bearing pockets are supplied with pressurized oil via a separate pressure connection. As a result, the output shaft is centered radially and axially between liquid cushions and all metallic contact surfaces are permanently separated from each other by a thin liquid film. This eliminates wear caused by metallic friction in any operating state, even at zero speed compared to hydrodynamic plain bearings. In conjunction with highly dynamic control valves and angle of rotation sensors, these actuators are preferably used in controlled systems in which disturbance variables such as friction and the stick-slip effect must be reduced to a minimum. Furthermore, due to the lack of internal seals, they are ideal for test series with large numbers of load cycles where an interruption, e.g. due to the replacement of internal seals, is not permitted.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The output shaft of the HSH swivel motors has radial and axial hydrostatic bearings. Here, radially and axially arranged bearing pockets are supplied with pressurized oil via a separate pressure connection. As a result, the output shaft is centered radially and axially between liquid cushions and all metallic contact surfaces are permanently separated from each other by a thin liquid film. This eliminates wear caused by metallic friction in any operating state, even at zero speed compared to hydrodynamic plain bearings. In conjunction with highly dynamic control valves and angle of rotation sensors, these actuators are preferably used in controlled systems in which disturbance variables such as friction and the stick-slip effect must be reduced to a minimum. Furthermore, due to the lack of internal seals, they are ideal for test series with large numbers of load cycles where an interruption, e.g. due to the replacement of internal seals, is not permitted.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The output shaft of the HSH swivel motors has radial and axial hydrostatic bearings. Here, radially and axially arranged bearing pockets are supplied with pressurized oil via a separate pressure connection. As a result, the output shaft is centered radially and axially between liquid cushions and all metallic contact surfaces are permanently separated from each other by a thin liquid film. This eliminates wear caused by metallic friction in any operating state, even at zero speed compared to hydrodynamic plain bearings. In conjunction with highly dynamic control valves and angle of rotation sensors, these actuators are preferably used in controlled systems in which disturbance variables such as friction and the stick-slip effect must be reduced to a minimum. Furthermore, due to the lack of internal seals, they are ideal for test series with large numbers of load cycles where an interruption, e.g. due to the replacement of internal seals, is not permitted.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The output shaft of the HSH swivel motors has radial and axial hydrostatic bearings. Here, radially and axially arranged bearing pockets are supplied with pressurized oil via a separate pressure connection. As a result, the output shaft is centered radially and axially between liquid cushions and all metallic contact surfaces are permanently separated from each other by a thin liquid film. This eliminates wear caused by metallic friction in any operating state, even at zero speed compared to hydrodynamic plain bearings. In conjunction with highly dynamic control valves and angle of rotation sensors, these actuators are preferably used in controlled systems in which disturbance variables such as friction and the stick-slip effect must be reduced to a minimum. Furthermore, due to the lack of internal seals, they are ideal for test series with large numbers of load cycles where an interruption, e.g. due to the replacement of internal seals, is not permitted.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quote

KFB CLARFELD GERMANY GMBH

Germany

Tapered roller bearings are composed of solid outer and inner rings with tapered raceways and tapered rollers with cage assembly. The bearings are separable. Therefore, the inner ring with the rollers and the assembly cage can fitted separated from the outer ring. Tapered roller bearings tolerate high radial and one sided axial forces. For axial steadying, a second bearing is usually necessary, which is then fitted mirror-inverted.

Request for a quote

KFB CLARFELD GERMANY GMBH

Germany

Axial needle cage assemblies Axial needle cage assemblies, composed of synthetic or metal axial cage assemblies with integrated needle rollers, have an extremely low overall height. They tolerate high axial forces acting in one direction, radial forces must be taken up separately. The deployment of axial needle cage assemblies requires that hardened and bevelled thrust surfaces may be used as raceways. Thrust bearing washers Thrust bearing washers are punched, hardened and polished and can be used as shaft or housing washers. These washers are appropriate when the adjoining machine part when not hardened, is rigid enough and of a stable form. Axial needle bearings Axial needle bearings are components made up of axial needle rollers and cage assemblies and axial washers with centring bore. They can be combined with needle sleeves, needle bushes and needle bearings. The thrust surface for the cage assembly must be hardened and bevelled. The product types AXK and K are applicable here

Request for a quote

TORWEGGE GMBH & CO. KG

Germany

Heavy-duty castors with polyurethane wheel - wheel body made of special grey cast iron with ball bearing - tread made of molded polyurethane, approx. 95° shore A - heavy welded steel construction The strongest Torwegge housing series consist of a welded steel construction for maximum dynamic stresses. The swivel castor housings are equipped with sealed axial rib ball bearing an tapered roller bearing and thus particularly sensitive against surges and beats. The housing head is screwed and secured by a heavy center bolt. The material polyurethane (PU) has a high load capacity with low abrasion. It also features high chemical resistance. These properties make polyurethane suitable for almost any application. In addition, PU offers low rolling resistance.

Request for a quote

TORWEGGE GMBH & CO. KG

Germany

Heavy-duty castors with polyurethane wheel - polyamide 6 wheel body with ball bearing - polyamide 6 can absorbs and release moisture - heavy welded steel construction The strongest Torwegge housing series consist of a welded steel construction for maximum dynamic stresses. The swivel castor housings are equipped with sealed axial rib ball bearing an tapered roller bearing and thus particularly sensitive against surges and beats. The housing head is screwed and secured by a heavy center bolt. The material polyamide (PA 6) is a high-quality plastic with a high load-carrying capacity. Polyamide is hygienic and odorless. It is also resistant to salt water, as well as many acids and alkalis up to a certain concentration. This material is often used in the food and pharmaceutical industries.

Request for a quote

TORWEGGE GMBH & CO. KG

Germany

Heavy-duty double castor with polyurethane wheel - wheel body made of special grey cast iron with ball bearing - tread made of molded polyurethane, approx. 95° shore A - heavy welded steel construction The strongest Torwegge housing series consist of a welded steel construction for maximum dynamic stresses. The swivel castor housings are equipped with sealed axial rib ball bearing an tapered roller bearing and thus particularly sensitive against surges and beats. The housing head is screwed and secured by a heavy center bolt. The material polyurethane (PU) has a high load capacity with low abrasion. It also features high chemical resistance. These properties make polyurethane suitable for almost any application. In addition, PU offers low rolling resistance.

Request for a quote

ODDESSE PUMPEN- UND MOTORENFABRIK GMBH

Germany

oddesse-propeller pumps are used for irrigation and drainage of agricultural areas, water-level regulation, oxygen enrichment of breeding water at fisheries, trimming of ships, ferries and tankers and so on. EXECUTIONS - Single-stage centrifugal pumps with open semi-axial impeller - Submersible, rewindable and water-filled motors with protection level IP 68 - Motor cooling through pumped medium that flows around it - Water-lubricated radial and axial slide bearings - Encapsulation of rewindable motor via mechanical seal - Optimal motor filling guaranteed by a volume-compensation system - Rubber-sheathed electrical cable, watertight connected - Continuous operation, switching operation or frequency control - Tandem operation - High-quality materials for application in service, industrial and seawater PERFORMANCE RANGE Delivery volume Q = … 1,000 m³/h Delivery height H = … 24 m

Request for a quote

JAKOB ANTRIEBSTECHNIK GMBH

Germany

• easy keyway connection • cost- effective type • with integrated ball bearing for high axial and radial load • torque range: 2 to 9000 Nm • shaft diameter: 6 - 90 mm

Request for a quoteResults for

Axial bearings - Import exportNumber of results

31 ProductsCountries

Category