- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- automotive parts

Results for

Automotive parts - Import export

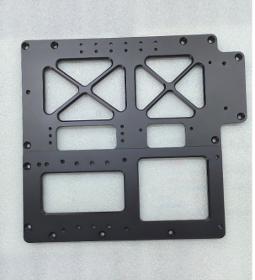

CIC - KLAUS CZERWONKA

Germany

Milling of complex components for automotive and mechanical engineering. Production of prototypes, test parts, small and large series according to data records, drawings, samples or specifications. Machining of cast and forged blanks. Attachment of decorative surfaces.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Nitriding treatment is a chemical heat treatment process in which nitrogen atoms penetrate the surface of the workpiece at a certain temperature and in a certain medium. The products treated with nitriding have excellent wear resistance, fatigue resistance, corrosion resistance and high temperature resistance. The general process of nitriding process :1. Pretreatment: clean, remove oil and dry the metal surface to ensure that the surface is clean and free of impurities. 2. Nitriding treatment: The metal is placed in an atmosphere containing nitrogen and treated at high temperatures to form a nitriding layer on the surface of the metal. 3. Post-treatment: Clean and cool the metal surface after nitriding to remove the residual nitride layer and prevent its oxidation. The nitriding process is of great importance for many industrial fields, such as tool manufacturing and automotive parts manufacturing.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Black oxidation treatment is a commonly used chemical surface treatment method for metal parts, including steel, stainless steel, copper and brass. The principle of this process is to immerse the metal in a heated solution containing oxidized salt, so that the metal surface forms a black oxide film to achieve the purpose of rust and corrosion resistance. This oxide film is usually iron tetraoxide (Fe304), which not only improves the corrosion resistance of the metal, but also gives it a black appearance. This surface treatment is widely used in areas such as precision machining projects, automotive parts, tools and decorations, and the advantages of black oxide include better corrosion protection, reduced light reflection, dimensional stability and aesthetic appeal. In short, the black oxidation treatment is a versatile technology suitable for the improvement and protection of various metal parts.

Request for a quote

SPIROL

Germany

SPIROL's Series 102 Coiled Spring Pins were designed specifically for use in automotive transmission assemblies. These transmission pins are available in standard and heavy duty to enable the designer to choose the optimum combination of strength, flexibility and diameter to suit different host materials and application requirements. All Series 102 transmission pins are 100% dimensionally controlled for consistency during assembly. Additional advantages include: • Absorbs shock and vibration • Non-interlocking • Symmetrical • Easy, trouble free assembly • Ideal for automatic installation • Global supply

Request for a quote

PRESSTECK S.P.A.

Germany

We are experts in deep-drawn parts made of stainless steel, deep-drawn parts made of aluminium and other non-ferrous metals (including brass, copper and nickel silver). To produce your perfect component, we also have the option of using carbon steel, special nickel alloys (e.g. Inconel®), but also soft magnetic materials. Each material has specific properties that need to be taken into account in the forming process. We manufacture deep-drawn parts with a diameter of 2 to 80 mm and a length of up to 120 mm. We process material thicknesses from 0.05 to 2.50 mm. Pharmaceuticals and medical technology, industry, consumer and automotive: we are primarily active in these fast-growing sectors. We are not only specialists in deep drawing, but also know the industrial requirements and process chains. Depending on your requirements, we complement deep-drawing with numerous secondary finishing processes up to fully automated assembly systems.

Request for a quote

PRESSTECK S.P.A.

Germany

Support sleeves for reinforcing plastic components. Made of stainless steel with customised design. The bushings can be produced not only round but also oval as a deep-drawn part.

Request for a quote

PRESSTECK S.P.A.

Germany

For our customers in the automotive and housing industry, we produce deep-drawn stainless steel pots with an integrated axle as a monobloc component. These are used in water pumps for electric vehicles. Our customer from the automotive industry needs pots with an integrated axle that holds a rotor. Up to now, the pot and axle have been joined in a centred manner by means of welding. The customer's wish was to produce a one-piece component to avoid welding. Deep drawing is the ideal technology for this. The size of the component required larger presses than were previously available. Therefore, we first developed tools as prototypes for larger presses on behalf of the customer. After practical tests at the customer's premises as well as at the end customer's, our client decided on a tool that was ideally suited for the production of the component in series.

Request for a quote

PEKU FOLIEN GMBH

Germany

Filling: The pre-opened bags-on-a-roll are opened manually or automatically by air blast and they are filled while still hanging on the roll. After filling, the bag is teared off and sealed. Lateral cardboard disks ensure the steady and exact unwinding of the roll. Holes can be punched in the bags, allowing air to escape during the packing process. The back of the bag can be coloured for better visibility of the bag’s content. A vertical tear-off perforation helps to re-open the filled bags. Applications: pre-opened bags on a roll are used wherever many small pieces have to be packed within a short time, e.g. in industries such as automotive, toys, plumbing parts, electronics, metal hardware, household products, medical and health care Order Quantity & Printing: Like all our packaging solutions, we offer our bags-on-a-roll in nearly every quantity, from small series to large production, printed with up to 10 colours or unprinted – directly from the manufacturer!

Request for a quote

GRONBACH

Germany

Gronbach manufactures decorative elements for the automotive industry in interior and exterior areas such as trim strips or trim parts made of aluminium, stainless steel and plastic hybrid technology. Functional components and plastic injection molded parts with a focus on fan wheels and turbines are also essential components of our technologies. As a specialist for surface finishing, you have a wide range of colours (anodising, powder coating), noble shapes and surfaces (brushing, grinding, polishing, blasting) and high-quality individualisation (screen printing, pad printing, under-anodising printing, laser engraving, etching techniques) at your disposal. In addition to the production of individual parts and the manufacture of complex assemblies as well as end products, we also offer you as a system supplier the complete project planning for new developments. Our portfolio includes: Automotive door sills Interior visible parts, e.g. side applications, decorative panels and...

Request for a quote

EWOQE GMBH & CO. KG

Germany

Welcome to EWOQE, your expert for prototype construction in precision mechanics! We offer a comprehensive range of services to meet your demanding requirements. Utilizing advanced 3D printing techniques such as FDM, SLS, MJF, and SLA, we deliver high-precision plastic components quickly and cost-efficiently. Our dedicated team is here to assist you with the design and manufacturing of prototypes, no matter their size or the quantity required. We understand the critical importance of quality and precision in precision mechanics and are committed to exceeding your expectations. Thanks to our additive manufacturing technologies, we can produce complex components with high accuracy, aiding you in efficiently achieving your development goals. Our express service also ensures fast turnaround times to optimize your time-to-market. Depend on EWOQE as your reliable partner for prototype construction in precision mechanics.

Request for a quote

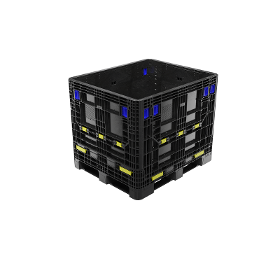

ORBIS EUROPE

Germany

ORBIS reusable bulk containers are designed to protect and transport heavy parts in automotive and industrial applications. Engineered for rugged applications, the plastic bulk containers are extremely robust and offer comprehensive product protection over a long service life. The 1200 x 1000 plastic bulk containers are available in multiple heights for increased packing density. The collapsible design with a return ratio of up to 1 : 3 reduces the shipping of air during return transport to a minimum. Key features: - manufactured from recycled material - multiple heights, access door and bottom configurations - durable all-plastic design - improved workplace safety - easy, on-site repair and part replacement - 100% recyclable

Request for a quote

MERECS ENGINEERING GMBH

Germany

Development and construction of test systems for environmental simulation, i.e. climate and temperature tests as well as corrosion tests (e.g. MEMS testing and automotive durability tests on tilt sensors, inclination sensors, inertial sensors, inclination sensors, automotive parts and many more). - Adjustable humidity - Typical temperature ranges are -72 to + 120°C - Parallel testing and calibration of more than 100 DUTs simultaneously per test run - Various interfaces to the DUTs can be switched like CAN, LIN, Flexray etc. - Database connection and automated data analysis using Microsoft PowerBi can be added.

Request for a quote

EP EHRLER PRÜFTECHNIK ENGINEERING GMBH

Germany

Based on years of experience in the field of test bench metrology in the automotive industry, EP develops test bench solutions for various applications. We build test benches for testing automotive components such as heat exchangers, intercoolers, filters, valves and others. These are test benches on which e.g. supplier parts for the automotive industry are tested in production. Our specialist knowledge of the industry makes us a strong partner in this area.

Request for a quote

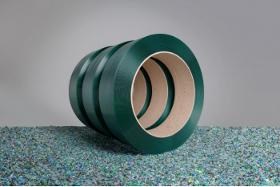

MOSCA GMBH

Germany

PET strapping is particularly tear-resistant and elastic at the same time. Thus they reliably absorb shocks during transportation and, depending on width, can sustain loads of between 185 and 580 kg. Our PET strapping is available in widths of 9.5 to 15.5 millimeters with tight fabrication tolerances. After use, it can be easily fed back into the material cycle, since it consists of 100 % recyclabled plastic bottles (bottle flakes). It has a high stability for optimal load security. Its constantly high quality ensures a high machine availability. Most frequent fields of application: • Corrugated cardboard industry • Printing industry • General logistics • Electrical industry (TVs, cooling/heating units, kitchen equipment) • Automotive industry (equipment and spare parts for cars, trucks and bikes)

Request for a quote

STOROPACK HANS REICHENECKER GMBH

Germany

EPP MEANS BEING ABLE TO HANDLE HEAVY LOADS EASILY. Expanded polypropylene (EPP) is the ideal basis for a tailored, reusable packaging solution, as the extremely durable material boasts high specific energy absorption. EPP can withstand strain such as shocks and even repeated impacts during transport – the material remains fully functional without any discernible damage and reliably protects the packaged goods. Storopack’s tailored, stackable EPP packaging can be used for solutions with high circulation, such as cargo carriers for the transport of sensitive parts in the automotive industry. An intelligent and, at the same time, simple reusable solution, available in a variety of colors and completely recyclable.

Request for a quote

TECHNOLOGICA GESELLSCHAFT FÜR HIGH TECH MATERIALIEN UND VERFAHREN MBH

Germany

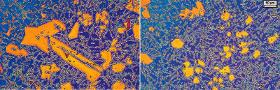

ALCUP is an innovation conceived, developed and produced by Technologica. It is a master alloy for the manufacture of special aluminium alloys used in automotive parts such as pistons and engine blocks. In the silicium alloys used for such parts, large, hard and brittle silicium crystals are usually found. The addition of ALCUP dependably prevents this, significantly refining the structure.

Request for a quote

HITACHI HIGH-TECHNOLOGIES EUROPE GMBH

Germany

Already the standard spectrometer configuration allows you to analysis: - automotive parts, such as bolt, nuts, and design parts etc. - electrical components & parts, such as PCB, connectors etc. - jewellery The advanced collimator design and the used cost-effective proportional counter detector enable high speed measurement over a wide thickness range as used in (multi-) layer structures such as automotive parts, electronic parts and components. Furthermore, the following functions realize an easy and efficient measurement: A new autofocus & auto approach function allows to focus automatically and ensure safe and rapid measurement with a greatly enhanced high level of easy operability. Using this function also enables to focus and to measure even if the samples show large variations in height, without adjusting height at same measurement condition. An optional wide view CCD camera allows positioning and multi-point measurement easily over a larger sample area. This spectromet

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TOPCOD DEUTSCHLAND GMBH & CO. KG

Germany

When containers are shipped and stored, they are often exposed to extreme climatic conditions. Especially on the high seas, there are very strong temperature fluctuations. This causes condensation ("container rain") to form inside the container, which can damage your goods. To prevent this, we use special desiccant chains that reduce the humidity in the container and thus protect the goods from damage, mold and corrosion. Universal application possibilities Costeffective The operating principle of our container desiccant is based on a mix of calcium chloride (CaCl2) and starch. This mix of materials binds the resulting moisture and prevents it from being released again thanks to the leakproof nonwoven fabric. Automotive parts Metal parts Electronics Grocery area Clothing and leather products Furniture Groceries Cardboard boxes and wood products Medical products

Request for a quote

F. ZIMMERMANN GMBH

Germany

The FZ33 compact combines a wide range of applications with excellent price/performance ratio and proven Zimmermann technology. Take advantage of these features for economical machining for a wide variety of parts for Aerospace, Automotive, Tool and Die, as well as many specialty applications. The rigid monolithic structure eliminates special foundations and provides a cost-effective and variable installation in small spaces. Focusing on the power spectrum to machine small and medium size parts, Zimmermann sets new standards and guarantees the user an enormous amount of flexibility and value – in other words, a low business risk due to an attractive cost price, stable machine value and thanks to its flexibility ensured added value.

Request for a quote

EPLUS3D TECH GMBH

Germany

EP-M300 is a marvelous metal printer that makes the production of reliable and high quality large metallic parts viable on industrial scale, with 500W/1000W single or dual laser optional, an ideal choice for big sized parts and batch production efficiently.

Request for a quoteResults for

Automotive parts - Import exportNumber of results

21 ProductsCountries

Company type

Category

- Forming - steels and metals (3)

- Vehicles - mechanical components and parts (1)

- Boxes, plastic (1)

- Testing equipment (1)

- Bags, plastic (1)

- Bar code scanners (1)

- Dynamos (1)

- Heat exchangers (1)

- Industrial resin coatings (1)

- Measurement and control instruments (1)

- Milling - machine tools (1)

- Packing and packaging - machinery and equipment (1)

- Printers - computer (1)

- Prototypes, industrial (1)

- Rolling machines (1)

- Screw cutting - steels and metals (1)

- Silicones (1)