- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- automatic assembly

Results for

Automatic assembly - Import export

HOCHRAINER GMBH

Germany

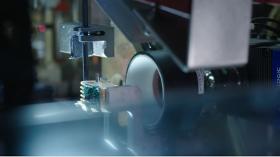

Semi-automatic assembly module for automotive joints, constructed as a chaku chaku system.

Request for a quote

HOCHRAINER GMBH

Germany

Fully automatic assembly system for complete assembly of joints Automatic change-over between part types is handled by robotic solutions.

Request for a quote

RALF LANG MASCHINENBAU GMBH

Germany

Pressing bearings Manually assemble anti-knock on hand lever press Automatically assemble and test retaining ring

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

The TEC 20 form, fill and seal machine enables the production of bags made of polyethylene film from a flat film roll. The film can be neutral or coloured, with continuous printing or centred printing with print mark. The design of the machine and the low loading height allow ergonomic adaptation to a manual feeding station or easy connection to a feeding unit, such as an automatic counter, an automatic weighing system, an automatic assembly machine, an injection moulding machine, a conveyor belt or similar.

Request for a quote

SPIROL

Germany

Offered with or without a head, Straight Pins are distinguished by their uniformity. The chamfered ends are more consistent than tumbled edges—making installation with automatic assembly equipment more reliable. Straight Pins are retained by compressing the host, not the inflexible solid pin. They are suitable for use in plastics for press-fit applications limited to those cases where the host material can withstand compression in the order of 0.05mm – 0.08mm (.002” – .003”). Straight Pins are often used to replace Ground Dowels in applications that do not require the tight tolerances of a Ground Dowel.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

RK ROSE+KRIEGER GMBH

Germany

RK Easywork – workstation systems tailored individually to your production process Ergonomics and the optimum coordination of all workflows are key features of the height-adjustable RK Easywork workstation systems from RK Rose+Krieger. This protects the well-being of employees and increases productivity. The requirements of a manual workstation system are numerous, especially in the area of small and medium-sized series. As well as ergonomics, an optimum combination of manual, semi-automatic and fully automatic assembly and inspection procedures represents the biggest challenge when designing a user-friendly workstation. With the RK Easywork selection assistant, a complete assembly workstation can be configured online to meet ergonomic and task-specific requirements. BLOCAN® construction profiles made from aluminium and the electrically driven lifting columns offer a perfect combination for the creation of high-quality table concepts.

Request for a quote

SPIROL

Germany

SPIROL's Series 102 Coiled Spring Pins were designed specifically for use in automotive transmission assemblies. These transmission pins are available in standard and heavy duty to enable the designer to choose the optimum combination of strength, flexibility and diameter to suit different host materials and application requirements. All Series 102 transmission pins are 100% dimensionally controlled for consistency during assembly. Additional advantages include: • Absorbs shock and vibration • Non-interlocking • Symmetrical • Easy, trouble free assembly • Ideal for automatic installation • Global supply

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Alongside the standard ICT/FCT process, we can also target every individual production stage for verification, as requested. Efficient inspection strategies and final functional tests are a fixed component of our quality management system. For components of the most varied shapes and with diverse electronics components, we will set up our AOI stations according to individual needs and provide reliable optical control of the overall assembly. Automatic optical inspection of your components is naturally part of our service range.

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— For the cooling of blow-down water and the recovery of heat from desalinated water/condensate — Increase in system efficiency of up to 2% — Reductions in fuel, cooling water and waste water costs — Rigorous compliance with official requirements thanks to automatic operation — Fast and easy assembly, requires just a small number of connections before it can be used

Request for a quote

FATH GMBH

Germany

Automatic connector with self-cutting thread; profile slot 5, 6, 8, 10, 12 for fast and solid connection of two aluminium profiles, assembly without machining Different versions — Cutting sleeve with assembly set for profile with screw and T-slot nut or hammer nut — Cutting sleeve without assembly set — Single or double connector — Plug-in connector, butt connector or corner connector Choice of material — Steel, zinc plated — stainless steel — ESD-compatible Other possible accessories: — Cover cap to cover the automatic connector — swivelling double slot nut different lengths with several threads in multiple threads in different sizes available on request

Request for a quote

SK-ELEKTRONIK GMBH

Germany

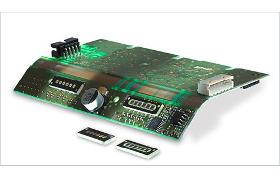

The SK-Elektronik GmbH Erfurt is your partner for a fast and flexible printed circuit board assembly of sample and small series manufacturing. We are a service provider for manual and automatic assembly of circuit boards in SMD and THT technology.

RAFI ELTEC GMBH

Germany

RAFI Eltec is a technical services provider that develops and produces electronic assemblies and systems according to customer-specific requirements – from the idea to the finished product. Efficient production processes and reliable execution of the overall implementation are characteristic for RAFI Eltec. As a result of our many years of experience in energy measurement technology and in radio and network applications, we have accumulated unique production and testing expertise. This is also naturally to your advantage in regard to the final assembly of your devices. Final assembly - Assembly presses and screw fittings - Ultrasonic welding - Adhesive robots - Semi-automatic and fully automatic assembly - Automated testing - Laser or inkjet printing technologies - Leak tests - Box build You can rely on support from the right contact partner for you – whether you are approaching us for the first time or during the production process.

Request for a quote

RAFI ELTEC GMBH

Germany

RAFI Eltec is a technical services provider that develops and produces electronic assemblies and systems according to customer-specific requirements – from the idea to the finished product. At RAFI Eltec, we test the quality of our products across all manufacturing processes. By performing individual tests and integrating fully automatic tests in combined assembly and testing lines, we achieve targeted and effective test cost reductions. For this purpose, we insist on the most cutting-edge technologies and high-quality equipment. Testing technologies - Pull test for chip-on-board - Automatic optical inspection - Flying probe - In-circuit test - Boundary scan test - Function test - Burn-in test and run-in test - Temperature shock test - Temperature humidity test You can rely on support from the right contact partner for you – whether you are approaching us for the first time or during the production process. We expertly answer all your questions.

Request for a quote

RAFI ELTEC GMBH

Germany

RAFI Eltec is a technical services provider that develops and produces electronic assemblies and systems according to customer-specific requirements – from the idea to the finished product. RAFI Eltec operates 5 fully automatic SMD high-speed, precision assembly lines with nitrogen reflow soldering technology. Our focus: - BGA, µBGA, CSP - QFN, Finepitch - 0201 - Novel components - Package-on-package - Automatic optical inspection Providing maximum quality for your ideas and products is what motivates us. To achieve this, we introduce our high quality standards to projects even before manufacturing begins. As a result of our expert analysis of customer data, potential pitfalls are eliminated in advance. We document sample productions in detailed test reports and discuss them with you. Due to our state-of-the-art testing technology and our in-house test equipment construction, we increase the quality of your production while simultaneously reducing logistics costs.

Request for a quoteResults for

Automatic assembly - Import exportNumber of results

15 ProductsCountries