- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- aluminum oxidation

Results for

Aluminum oxidation - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Golden anodizing specifically refers to creating a layer of golden oxide on the metal surface through the anodizing process. Golden anodized surfaces have a beautiful, metallic gold hue. The color is not only aesthetically pleasing but also provides additional durability and corrosion resistance to the metal.Decorative Purposes: Golden anodizing is often used for decorative purposes, such as architectural elements, jewelry, and consumer electronics. Functional Uses: Beyond aesthetics, it also serves functional purposes, such as preventing galling of threaded components and creating dielectric films for electrolytic capacitors. golden anodizing combines both functionality and aesthetics, making it a popular choice for various applications. Whether you’re looking to enhance the appearance of a product or improve its durability, golden anodizing is a versatile process that delivers impressive results.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

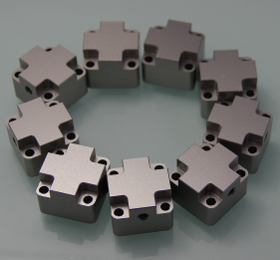

These are the accessories made by aluminum, which used in many fields ,such as industrial, medical equipment and other industries.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Anodized aluminum is a process that enhances the durability and resistance of aluminum by creating a protective oxide layer on its surface. This layer not only prevents corrosion and wear but also allows for custom surface coloration. Here are some key points about blue anodized aluminum: Color Options: Aluminum can accept a wide spectrum of anodized colors, including blue. Other available colors include pink, black, silver, gold, green, orange, red, and purple.Anodization serves multiple purposes: Corrosion Resistance: The protective oxide layer acts as a barrier against corrosion. Aesthetics: Anodized aluminum looks sleek and reflective due to the uniform oxide layer. Scratch Resistance: The tough anodic finish increases scratch resistance. Other Qualities: Anodization also affects wear resistance, heat dissipation, and adhesion. blue anodized aluminum combines aesthetics with functionality, making it a popular choice for various applications.

Request for a quote

GURTEC GMBH

Germany

Belt width: 500-1400 mm Recommended speed: max. 3.0 m/s Quick and simple exchange of wear parts Blade material: polyurethane (optional + aluminum oxide granulate)

Request for a quote

GURTEC GMBH

Germany

Belt width: 1200-2400 mm Pulley diameter: 800-1500 mm Recommended speed: max. 4.5 m/s Blade material: polyurethane (optional + aluminum oxide granulate)

Request for a quote

GURTEC GMBH

Germany

Belt width: 500-1400 mm Pulley diameter: 320-630 mm Recommended speed: max. 3.0 m/s Blade material: polyurethane (optional + aluminum oxide granulate)

Request for a quote

GURTEC GMBH

Germany

Belt width: 500-1400 mm Recommended speed: max. 3.0 m/s Quick and simple exchange of wear parts Blade material: polyurethane (optional + aluminum oxide granulate)

Request for a quote

GURTEC GMBH

Germany

Belt width: 500-1800 mm Pulley diameter: 320-630 mm Recommended speed: max. 3.5 m/s Quick and simple exchange of wear parts Blade material: polyurethane (optional + aluminum oxide granulate)

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX PeenPearl® are the new mineral abrasives with the perfect spherical shape. It consists of aluminum oxide (Al₂O₃) in combination with a high content of titanium dioxide (TiO₂). Its texture is exceptionally dense and resistant to breakage. Other mineral blasting material, such as glass-beads are indirection lifetime exceeded many times over. According low is the dust in a blasting room as well as the volume of waste for disposal. WIWOX PeenPearl® produces extremely smooth, shiny surfaces, ideal for the visual appearance of high-quality components. By the uniform compaction can functional Surfaces to be improved in their properties (Shot-Peening effect). The contained iron oxide (TiO₂) is completely crystalline bound. Ferrite residues on Surfaces are therefore excluded. For the processing of stainless steels and nonferrous metals opened WIWOX PeenPearl® blasting abrasives new perspectives.

Request for a quote

MBW GRUPPE

Germany

The anodising process used at mbw is used for the surface treatment of die-cast aluminium. By anodic oxidation, wear and corrosion resistance, as well as the natural protective coating of the base material, are improved. Anodising increases wear and corrosion resistance. This process is suitable for rack goods

Request for a quote

DR.-ING. MAX SCHLÖTTER GMBH & CO. KG.

Germany

Anodizing stands for electrolytic oxidation of aluminum and is a process for strengthening the natural oxide layer present on aluminum through anodic oxidation. Unlike traditional electroplating processes, anodizing dissolves the top layer of aluminum and converts it into aluminum oxide. The resulting oxide layer protects the underlying workpiece from corrosion.

Request for a quote

LINOX GMBH

Germany

Hematite Magnetite Goethite Siderite Iron Oxide Chrome Ore Pyrite Sulphur Fluorspar Ilmenite Bauxite Manganese Ore Manganese Dioxide Aluminium Oxide Ferro Alloys Silica Sand Silica Sand Substitutes Mill Scale Gypsum Anhydrite Dihydrite

Request for a quote

GESCO-METALL GMBH SCHOTTENHAMML-BIEGETECHNIK

Germany

For over 30 years, GESCO-metall GmbH has stood for quality, competence and experience in the field of contract bending. The production focuses are curved parts for windows, doors and facades as well as complex special profiles for industrial construction, vehicle manufacturing, plant engineering and medical technology. It goes without saying that we also bend aluminium cover caps for the wood/aluminium field. Our bending technology range is rounded off by complete curved elements, including electrolytic oxidation of aluminium, powder coating, metal fittings and glass together with window sills and soffit cladding. You will find more information about bending technology, contract bending, profile bending, portholes, in our product section: Contract Bending Work, Curved Elements, Window Sills, Portholes, Glazing Frames – Door Windows.

Request for a quote

RHODIUS ABRASIVES GMBH

Germany

Continuous-feed belt with standard aluminium oxide for stationary belt grinders. • Aluminium oxide closed coating for high material abrasion on steel • Tear-resistant Y-polyester fabric, waterproof for long lifetime • Safe through three full-face fabric layers

RHODIUS ABRASIVES GMBH

Germany

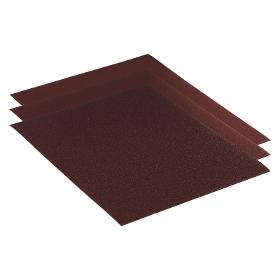

Abrasive paper with a paper backing and semi-open aluminium oxide coating. • Particularly suitable for paints and varnishes • Half-open coating for non-aggressive grinding • Good for wood finishing

RHODIUS ABRASIVES GMBH

Germany

Abrasive paper with especially flexible cloth backing. • Closed coated aluminium oxide for high material abrasion • Synthetic resin bonding for long lifetime

RHODIUS ABRASIVES GMBH

Germany

Rolls with paper backing and semi-open aluminium oxide coating. • Particularly suitable for paints and varnishes • Half-open coating for non-aggressive grinding • Good for wood finishing

Do you sell or make similar products?

Sign up to europages and have your products listed

RHODIUS ABRASIVES GMBH

Germany

Self fastening disc with hole system for Festool/Bosch machines. • Closed coated aluminium oxide for high material abrasion • Synthetic resin bonding for long lifetime

RHODIUS ABRASIVES GMBH

Germany

Self fastening disc with hole system for Festool/Bosch machines. • Closed coated aluminium oxide for high material abrasion • Synthetic resin bonding for long lifetime

RHODIUS ABRASIVES GMBH

Germany

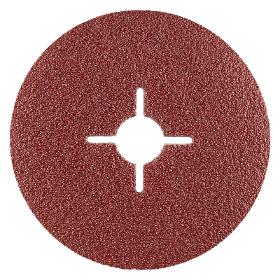

Aluminium oxide fibre disc – the grain enables superior stock removal performance on steel. • Good stock removal performance • Long lifetime • Few sparks

RHODIUS ABRASIVES GMBH

Germany

Standard aluminium oxide flap disc with fibre glass support. Excellent performance on steel. • Long lifetime • Quick stock removal • Tough fibre glass carrier

RHODIUS ABRASIVES GMBH

Germany

Standard aluminium oxide flap disc with polyamide support. Excellent performance on steel. • Long lifetime • Quick stock removal • Vibration-reducing polyamide support

RHODIUS ABRASIVES GMBH

Germany

Aluminium oxide fibre disc for the quick change system – the grain enables excellent stock removal performance on steel. • Good stock removal • Long lifetime • Rapid tool changeover without sticking or slippage

RHODIUS ABRASIVES GMBH

Germany

Abrasive sleeves for mounting the matching SHEK expanding body. Cotton interior reinforcement. • High stock removal performance • Small dimensions for working where space is at a premium • Aluminium oxide, for processing steel

RHODIUS ABRASIVES GMBH

Germany

Continuous-feed belt for belt grinders. • Aluminium oxide closed coating for high material abrasion on steel and wood • Tear-resistant X-cloth for long lifetime • Safe through three full-face fabric layers

KAPP NILES GMBH & CO. KG

Germany

Beside the non-dressable CBN grinding tools, dressable grinding tools of leading manufacturers can be used on our machines, too. Vitrified bond aluminium oxide tools are dominant. Sintered aluminium oxide is preferred as the grinding tool for grinding of steel due to its resilience and grinding capability. Gray cast-iron can also be processed with normal aluminium oxide. The profiling of the grinding tools takes place via a machine-integrated CNC dressing unit. A diamond-plated, rotating dressing tool profiles the wheel in accordance with the respective gear parameters. The grinding tool is conditioned specifically for rough or finish grinding by selecting respective technological dressing parameters. Form consistency and cutting capacity of the grinding wheel is assured by repeated dressings, dependent on pre-defined stock removal rates. The automatic balancing produces smoother turning for larger grinding tools, and consequently, high gear quality. dressable CBN tools Single-layere

Request for a quote

LECHMANN ENGINEERING GMBH

Germany

The anodizing process is the creation of an oxidic protective layer through anodic oxidation in the uppermost aluminum zone. A 5 to 25 μm thin, resistant hard layer is created that protects against corrosion. — Semi-automatic anodizing plant, processing dimensions 4000 x 1000 x 500 mm — hand anodizing plant, processing dimensions 2500 x 700 x 500 mm

Request for a quoteResults for

Aluminum oxidation - Import exportNumber of results

28 ProductsCountries

Company type

Category

- Conveyor belts (2)

- Metal brushes (2)

- Aluminium coatings (1)

- Bending - steels and metals (1)

- Chemicals - Basic Products & Derivatives (1)

- Heating and air conditioning - works (1)

- Minerals (1)

- Organic oxides and peroxides (1)

- Precious and semiprecious stones and pearls (1)

- Sections - non-ferrous metal (1)

- Street-cleaning machines (1)

- Transmission belts (1)