- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- aluminium center

Results for

Aluminium center - Import export

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Strong crimped plug/cable attachment Circular cable cross section to reduce kinking and twisting Various cable lengths available Types: MicroMag surface + air thermocouples Easy to place, ideal for difficult-to-access car body shell areas Encapsulated magnet design allows reliable direct use even on wet painted and e-coated substrates IRMAG surface thermocouple Designed to measure ferrous substrates in IR cure ovens Robust alternative to Adhesive Patch thermocouple, combines easy attachment and fast thermocouple response Magnetic surface + air thermocouples Magnet offset from sensor prevents heatsink effect PTFE handle for easy removal or repositioning PTFE-coated to prevent sticking Aluclamp surface thermocouple Clips onto the edge of an aluminum car hood or other nonferrous panel Allows measurement of surface temperature at center of panel Aluminum automotive thermocouples with a spring-loaded bobbin for use on aluminum car body shells

Request for a quote

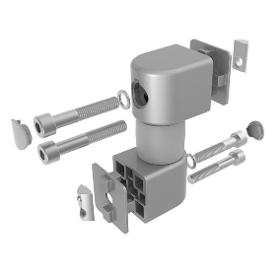

FATH GMBH

Germany

Description: Connection joint with friction for the creation of system arms using profile pieces; pivotable 360°; friction joint can be attached lateral, transverse, or on the face of the profile; if attached on the front face, the core hole of the respective profile must be M8 threaded (min. 15 mm deep) Material: Housing: Aluminum die-cast Cover ring: Plastic Inserts: Steel Friction shaft: Steel Cover caps: Plastic Screws: Steel Washers: Steel Centering plates: Aluminum die-cast T-slot nuts: Steel Surface: Housing: Laquered Centering plates: Laquered Screws: Zinc plated Washers: Zinc plated T-slot nuts: Zinc plated Color: Housing: Alu color Cover ring: Gray ≈ RAL 7042 Cover caps: Gray ≈ RAL 7042 Centering plates: Alu color Set: Various Sets available - Please contact us for Details Pack Quantity: 1 piece/set

Request for a quote

STARRAG GMBH

Germany

High performance simultaneous 5 axis machining center for aluminum structures Efficient high performance machining requires a rugged machine buildup without weakness. All technical parameters such as axis strokes, forces, torques and accelerations are set according to application requirements. The design of the STC X series has no bottleneck reducing the maximum possible material removal rates. With its design, unmatched productivity is possible. The STC X machine enhancement is ever ongoing. The goal is to continuously increase the customer benefits, i. e. increase productivity, increase accuracy or expand the application options.

Request for a quote

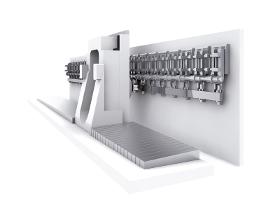

STARRAG GMBH

Germany

This highspeed machining center for long aluminium stringer components combines the advantages of SprintZ3 technology with rapidity and accuracy to provide efficient work piece machining with optimised workpiece handing. The machine is specially designed for machining aluminium profiles (or stringers) of up to 30 metres in length. Thanks to the excellent precision and speed the ECOLINER user can achieve high cutting rates (average machining time of 12 minutes per linear meter), optimum accuracy and excellent surface quality, even with extremely long stringers.

Request for a quote

STARRAG GMBH

Germany

High performance simultaneous 5 axis machining center for aluminum structures Efficient high performance machining requires a rugged machine buildup without weakness. All technical parameters such as axis strokes, forces, torques and accelerations are set according to application requirements. The design of the STC X series has no bottleneck reducing the maximum possible material removal rates. With its design, unmatched productivity is possible. The STC X machine enhancement is ever ongoing. The goal is to continuously increase the customer benefits, i. e. increase productivity, increase accuracy or expand the application options

Request for a quote

STARRAG GMBH

Germany

High performance simultaneous 5 axis machining center for aluminum structures Efficient high performance machining requires a rugged machine buildup without weakness. All technical parameters such as axis strokes, forces, torques and accelerations are set according to application requirements. The design of the STC X series has no bottleneck reducing the maximum possible material removal rates. With its design, unmatched productivity is possible. The STC X machine enhancement is ever ongoing. The goal is to continuously increase the customer benefits, i. e. increase productivity, increase accuracy or expand the application options.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Aluminium center - Import exportNumber of results

6 ProductsCountries

Company type