- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- adjustable shock absorbers

Results for

Adjustable shock absorbers - Import export

(-HT-LT)_FA_IMG_Single-01-cut-Labels_RGB-L__ffdb704f.jpg)

ACE STOSSDÄMPFER GMBH

Germany

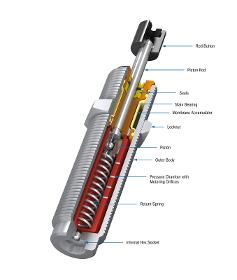

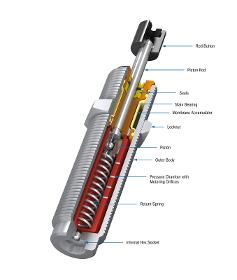

Adjustable Energy capacity 1,135 Nm/cycle Stroke 23.2 mm Adjustable and unique: These industrial shock absorbers from ACE, which can be precisely adjusted both at the front and rear, also contribute towards the success of the MAGNUM series. Equipped with excellent sealing technology, an annealed guide bearing and integrated positive stop, they are robust and durable. These dampers absorb 50 % more energy than their predecessors but are built even more compactly. The larger range of effective loads also opens up various options in design and assembly. This makes the ML series especially suitable for effective loads of 300 kg to 500,000 kg. Where work is done with changing application data and wherever flexibility is required, they make the best option.

Request for a quote(-HT-LT)_FA_IMG_Single-01-cut-Labels_RGB-L__ffdb704f.jpg)

ACE STOSSDÄMPFER GMBH

Germany

Adjustable Energy capacity 425 Nm/cycle Stroke 23.1 mm Adjustable and unique: These industrial shock absorbers from ACE, which can be precisely adjusted both at the front and rear, also contribute towards the success of the MAGNUM series. Equipped with excellent sealing technology, an annealed guide bearing and integrated positive stop, they are robust and durable. These dampers absorb 50 % more energy than their predecessors but are built even more compactly. The larger range of effective loads also opens up various options in design and assembly. This makes the ML series especially suitable for effective loads of 300 kg to 500,000 kg. Where work is done with changing application data and wherever flexibility is required, they make the best option.

Request for a quote(-HT-LT)_FA_IMG_Single-01-cut-Labels_RGB-L__ffdb704f.jpg)

ACE STOSSDÄMPFER GMBH

Germany

Adjustable Energy capacity 170 Nm/cycle Stroke 23.2 mm Adjustable and unique: These industrial shock absorbers from ACE, which can be precisely adjusted both at the front and rear, also contribute towards the success of the MAGNUM series. Equipped with excellent sealing technology, an annealed guide bearing and integrated positive stop, they are robust and durable. These dampers absorb 50 % more energy than their predecessors but are built even more compactly. The larger range of effective loads also opens up various options in design and assembly. This makes the ML series especially suitable for effective loads of 300 kg to 500,000 kg. Where work is done with changing application data and wherever flexibility is required, they make the best option.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Energy capacity 56.5 Nm/cycle Stroke 18.7 mm Optimizing PET stretch blow machines: MAXIMACE, the new PET shock absorbers from ACE, shine with longer service life compared to previous solutions and an operating time of over 20 million strokes. They work simply and faster than other shock absorbers and are stronger at the same time. As a result, downtime is reduced and system performance and production volume are increased. This is accomplished by numerous details such as innovative aluminium outer housings for better heat dissipation, improved high temperature seals (up to approx. 107°C), a diaphragm accumulator for faster cycle times and a larger damper chamber which is filled with food-grade oil. All of this significantly contributes to reduced wear and extended service life. These self-adjusting, specialized shock absorbers stand out in their field of PET container production due to their compactness and distinctively colored aluminium bodies.

Request for a quote_FA_IMG_Single-01-cut-Labels_RGB-L_EN_d54ffcf9.jpg)

ACE STOSSDÄMPFER GMBH

Germany

Adjustable Energy capacity 4.0 Nm/cycle Stroke 10.2 mm The miniature shock absorbers from the MA30 to MA900 series can be adjusted and precisely adapted to your requirements. For example, the MA150 displays the rolling diaphragm technology from the MC150 to MC600 family and offers all of the advantages of this technology, such as use in pressure chambers. Thanks to long strokes (including 40 mm on the MA900) lower reaction forces result, which provide a soft damping characteristic. All variations of these units are maintenance-free, ready-to-install machine elements and have an integrated positive stop. They provide the best service where application data changes, where the calculation parameters are not clear or where maximum flexibility in the possible usage is required. The adjustable miniature shock absorbers from ACE can be used to meet precisly the customer's application and are therefore found everywhere in mechanical engineering and many other applications.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ACE STOSSDÄMPFER GMBH

Germany

Energy capacity 56.5 Nm/cycle Stroke 18.8 mm Optimizing PET stretch blow machines: MAXIMACE, the new PET shock absorbers from ACE, shine with longer service life compared to previous solutions and an operating time of over 20 million strokes. They work simply and faster than other shock absorbers and are stronger at the same time. As a result, downtime is reduced and system performance and production volume are increased. This is accomplished by numerous details such as innovative aluminium outer housings for better heat dissipation, improved high temperature seals (up to approx. 107°C), a diaphragm accumulator for faster cycle times and a larger damper chamber which is filled with food-grade oil. All of this significantly contributes to reduced wear and extended service life. These self-adjusting, specialized shock absorbers stand out in their field of PET container production due to their compactness and distinctively colored aluminium bodies.

Request for a quote_FA_IMG_Single-01-cut-Labels_RGB-L_EN_d54ffcf9.jpg)

ACE STOSSDÄMPFER GMBH

Germany

Adjustable Energy capacity 4.0 Nm/cycle Stroke 10.2 mm The miniature shock absorbers from the MA30 to MA900 series can be adjusted and precisely adapted to your requirements. For example, the MA150 displays the rolling diaphragm technology from the MC150 to MC600 family and offers all of the advantages of this technology, such as use in pressure chambers. Thanks to long strokes (including 40 mm on the MA900) lower reaction forces result, which provide a soft damping characteristic. All variations of these units are maintenance-free, ready-to-install machine elements and have an integrated positive stop. They provide the best service where application data changes, where the calculation parameters are not clear or where maximum flexibility in the possible usage is required. The adjustable miniature shock absorbers from ACE can be used to meet precisly the customer's application and are therefore found everywhere in mechanical engineering and many other applications.

Request for a quote_FA_IMG_Single-01-cut-Labels_RGB-L_EN_d54ffcf9.jpg)

ACE STOSSDÄMPFER GMBH

Germany

Adjustable Energy capacity 5.5 Nm/cycle Stroke 7.2 mm The miniature shock absorbers from the MA30 to MA900 series can be adjusted and precisely adapted to your requirements. For example, the MA150 displays the rolling diaphragm technology from the MC150 to MC600 family and offers all of the advantages of this technology, such as use in pressure chambers. Thanks to long strokes (including 40 mm on the MA900) lower reaction forces result, which provide a soft damping characteristic. All variations of these units are maintenance-free, ready-to-install machine elements and have an integrated positive stop. They provide the best service where application data changes, where the calculation parameters are not clear or where maximum flexibility in the possible usage is required. The adjustable miniature shock absorbers from ACE can be used to meet precisly the customer's application and are therefore found everywhere in mechanical engineering and many other applications.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The RSA Series is designed to identify suspension springs with the appropriate load class based on an individual payload measurement result. The system receives the measurement results from the upstream system. The system is available as a single or double cycle version (depending on the required throughput). Simple linear axes, single- or twin-robot systems are used as handling systems. Since the labels are normally wider than the distance between the threads, the label is preformed (Ushape) before application to reach the labelling position before it is placed around the wire and finally fixed as a flag label. The data is inspected by a vision system and compared with the original measurement information at the outfeed of the system (verification). The labels are printed in the system with various data such as customer information, barcodes and line information. The data for this is made available via the main control of the production line.

Request for a quote

LEBEN-DÄMPFUNGSTECHNIK GMBH

Germany

The hydraulic industrial shock absorber of the C-series (COMPENSER®) is the ideal hydraulic buffer for storage and retrieval machines or smaller conveyor systems, crane systems, test stands etc. in light to medium mechanical engineering. Due to its short design, this hydraulic buffer (COMPENSER®) can be used in a spacesaving manner as limitation of the end position (as emergency end stop) in industrial applications. In addition, the low reset force allow operational pushin cycles at creep speed. Design & Function: The piston rod 2 enters the metering tube 3. The damping medium flows from the pressure chamber 6 through the throttle orifices 4 of the metering tube 3 into the volume balance chamber 5. The nitrogen gas between the outer tube 7 and the metering tube 3 is compressed and stores the energy required for the reset of the piston rod. When the piston rod 2 returns to the initial position, the damping medium flows back into the pressure chamber 6.

Request for a quote

LEBEN-DÄMPFUNGSTECHNIK GMBH

Germany

Shock reducing elements by LEBENDämpfungstechnik GmbH known as hydrostatic, viscoelastic or elastofluid shock absorbers with an integrated springdamper operating principle. Advantage Use in pulling and pushing direction Small design Very high preload of the shock absorber Individual reset force of the piston rod depending on the application Used as a buffer in Railway couplings Water locks / sluices … Illustrated hydrostatic buffer Damping of the pretensioned rope catch (tensioned catch rope) in front of a water lock

Request for a quote

LEBEN-DÄMPFUNGSTECHNIK GMBH

Germany

The COMPENSER® of the KL-series is an industrial shock absorber for light mechanical engineering, e.g. handling equipment, small storage and retrieval machines and small crane systems. Due to the low reset force of the compression spring, this buffer of the KL-series is well suited for operational push-in cycles at creep speed. Design & Function: The piston rod 2 pushes the piston 6 into the pressure chamber 7. At the same time, the damping medium flows through the metering grooves placed in the outer tube 8, via the piston 6 and into the volume balance chamber 5. The return spring 3 is tensioned and, after the impact has occurred, pushes the piston rod 2 back to the initial position. By this the damping medium flows back into the pressure chamber 7.

Request for a quote

LEBEN-DÄMPFUNGSTECHNIK GMBH

Germany

The COMPENSER® of the DC-series is an ideal hydraulic shock reducing element especially for the application field of storage technology (storage and retrieval machines). As a doubleacting buffer, this industrial shock absorber can be used in a spacesaving manner due to its design and can be actuated alternately from both sides. The constructive design and function corresponds to the C-Type. Furthermore, due to its low reset force, it can easily be pressed in at creep speed during operation. As optional equipment PU caps as inserts for the impact cap for the reduction of impact noise and a monitoring of the piston rod‘s position (by either magnetic or inductive sensors) are available. If only a slight increase of reset force of the piston rod over the entire stroke is desired, an additional external accumulator can be fitted to the cylinder to increase the gas volume of the gas spring. Hence the reset force decreases in retracted state.

Request for a quote

LEBEN-DÄMPFUNGSTECHNIK GMBH

Germany

The preferred field of application for the (gas) hydraulic industrial buffer (COMPENSER®) of the S-series is in the medium to heavy engineering industry sector. As a heavy duty shock absorber it is used in large crane systems (e.g. harbour crane, shipyard crane or container crane), metallurgical plants, rolling mills, loading systems or as end stop integrated in a rail buffer stop. Design & Function: The gas-filled inner tube 2 enters the outer tube 9. The damping medium flows from the pressure chamber 6 through the throttle orifices 8 of the metering tube 7 into the volume balance chamber 5. The separating piston 4 simultaneously moves in the direction of the impact cap 1 and compresses the nitrogen gas filling. In the gas space 3, the energy is stored which is required for the reset of the inner tube. When the inner tube 2 returns to the initial position, the separating piston 4 moves in the opposite direction and presses the damping medium back into the pressure chamber 6.

Request for a quote

LEBEN-DÄMPFUNGSTECHNIK GMBH

Germany

This design by LEBENDämpfungstechnik GmbH acts as a hydraulic shock absorber in both, pulling and pushing direction. The energy dissipation of this kind of industrial shock absorber is performed in two ways Working principle As a purely hydraulic variant (TwinStroke®) – in push (compression) direction hydraulically reversible by means of damping medium – in pull (tension) direction hydraulically reversible by means of damping medium The TwinStroke® dampens push and pull forces without an additional functional element. A piston system transmits the push and pull forces gashydraulically to different gas and oil chambers. In this way, any load can be absorbed immediately without idle stroke, socalled “slack”, and with minimal wear. The TwinStroke® can absorb changing loads very well. The smaller size and lower weight is advantageous, as only one element is needed to absorb compression and tension forces.

Request for a quoteResults for

Adjustable shock absorbers - Import exportNumber of results

16 ProductsCountries

Company type