- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- abrasives for metal

Results for

Abrasives for metal - Import export

NANO ABRASIVES GMBH

Germany

Einscheiben - Läppmaschine MA 600/3 - GR - DPS geregelter Antrieb, nano abrasives Dosierpumpensystem bestehend aus: - Maschine - Rollführungen - Läppscheibe - Abdichtringe - Dosierpumpensystem - Elektrik Die Maschine ist komplett (inkl. Motor) deutschen Ursprungs Harmonisierte Norm DIN EN ISO 12100:201 Maschinendaten: Länge der Maschine in mm 1300 Breite der Maschine in mm 1200 Höhe der Maschine in mm 1600 Tischbelastung in kg 200 Gewicht der Maschine in kg 1100

Request for a quote

ROCHOLL GMBH

Germany

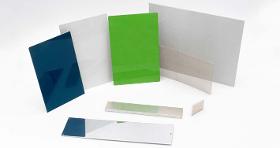

YOU TAKE CARE OF THE COLOR, WE TAKE CARE OF THE QUALITY For paint tests, we are able to produce paint test panels that are made of various materials, offering a wide range of coatings, shapes and surface finish options. Of course we attach great importance to meeting your requirements. Upon request, we supply bright-finish, degreased or pre-treated panels. Moreover, test panels can be provided with drilled holes or rounded corners. You can also order test specimens made of any common materials such as wood, glass, aluminum, steel or plastic for the TABER abraser test. From various metals From various plastics With boreholes Bare or pretreated Degreased and vacuum-packed Various sizes upon request Coil-coated aluminum or sheet steel upon request

Request for a quote

ROCHOLL GMBH

Germany

Are you aware of our finishing options for metal and aluminum test specimens? Chemical degreasing, deburring, grinding, turning, milling, punching or blasting – no problem. Upon request, test specimens can be customized and labeled with serial numbers. Contact us to find out how we can help you. By the way: we can manufacture test specimens for the TABER-ABRASER from all kinds of metals.

Request for a quote

ERC ADDITIV GMBH

Germany

ERC Throttle/Butterfly Valve Cleaning Spray breaks down stubborn impurities in the carburettor system and prevents major repairs. THE EFFECT Deposits and impurities in the intake and throttle valve area impair the function of the carburettor system and increase the risk of corrosion and expensive repairs. THE ADVANTAGES AT A GLANCE - Removes soiling in the intake and throttle valve area - Cleans grease, dirt, and oil residue, as well as rubber abrasion off of metal surfaces - Can be used on (carburettor) linkages, cable wire passages and metal bearings

Request for a quote

NORIS GROUP GMBH

Germany

Non-contacting multi-channel stainless-steel speed sensor, eddy current principle. Due to its design and type approval according to DIN EN 50155 especially suitable for transport technology. Scanning of all electrically conductive materials (steel or aluminium). Insensitive against mechanical abrasion (metal chips). Robust and high quality housing: IP69 pressure-tight and individually tested at 5 bar (for details see technical data). Excellent vibration and shock resistance and double protection of the sensor head. Connection outlet straight or lateral; with protective tubing on request. Detection of very low speed (near zero speed).

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Contaminated bulk material is cleaned One of the most annoying and expensive problems with bulk material processing is the contamination by foreign substances. These contaminants not only reduce the quality of the final product, they also cause damage to the machines and failures. Especially high-strength small metal parts such as screws, nuts, washers, or cotter pins cause serious damage to the processing machinery. For this reason, the production costs with contract processing are often uncontrollable. Ebbecke has the production under control To solve this costly nuisance, the engineers of Ebbecke Verfahrenstechnik AG have developed their own system with which goods that have been contaminated by metal particles can be cleaned. This is done using the inductively-working metal detector that detects even the finest metal abrasions and reliably separates them from the goods. Through a trouble-free production process delays, non-compliance of supply contracts and consequent compensatio

Request for a quote

LECHMANN ENGINEERING GMBH

Germany

Grinding is an abrasive manufacturing process for processing surfaces with abrasives. The result is metallically pure surfaces free of residues (further processing) and uniform micrographs with high dimensional and shape accuracy and low waviness/roughness. — Lissmac SMW535: max. width 1250mm (grinding, satin finishing and highly decorative processing in one operation) — Kuhlmeyer type ZBS3: max. 4000 x 750 mm — Metallkraft MBSM 2000 ZB: max. 2000 x 750 mm

Request for a quoteResults for

Abrasives for metal - Import exportNumber of results

8 ProductsCountries

Company type