- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- 3d sensors

Results for

3d sensors - Import export

MICRO-EPSILON

Germany

The new generation of Micro-Epsilon’s 3D sensors impresses with high accuracy during measurement and assessment of components and surfaces. The surfaceCONTROL and reflectCONTROL inspection systems from Micro-Epsilon are intended for matt and shiny surfaces respectively. The 3D snapshots are recorded in a short time and provide detailed 3D point clouds. These 3D sensors are used, e.g., for geometric component testing, position determination, presence checks and the measurement of flatness or planarity. Thanks to their high performance, the sensors are used for inline applications, on robots and also for offline inspection.

Request for a quote

MICRO-EPSILON

Germany

The precise and compact surfaceCONTROL 3D 3500 3D sensor is ideal for automated inline inspection of geometries, shapes and surfaces on diffuse reflective surfaces. With a z repeatability of up to 0.4 µm, the sensor sets new standards in high-precision 3D metrology.

Request for a quote

QUELLTECH GMBH

Germany

Q6-Lasor sensor – High Speed, High Resolution – Q6 Sets New Standards for 2D / 3D Measurement: Resolution of up to 0.6 µm Profile speed of up to 25.000 profiles/s Measuring ranges between 2 mm and up to 370 mm available Laser wave lengths starting from UV via blue, red and green through to IR The Q6 laser sensor series has already proven its ability in numerous industrial applications demanding a high degree of precision and process stability at increased travel speed. For common environments, connection is established via GIGE interface and GeniCam. Integration with linear axes and robots is possible by means of encoder inputs and trigger option.

Request for a quote

QUELLTECH GMBH

Germany

Particular Challenge: For the assessment of rotating parts, numerous parameters have to be taken into consideration: Concentricity, radial run-out and axial run-out (i.e. wobble); furthermore thickness, diameter, planarity and the absence of surface defects had to be examined. The solution developed by QuellTech consists in a configuration of three Q6 Laser Laser Scanners.Each of the lateral surfaces is assigned to its own scanner. In order to enable the thickness precisely to be determined, both laser lines are mutually oriented in opposite direction. The third scanner inspects the outer circumference of the wheel, this way measuring diameter and radial run-out. All of these scanners are subject to encoder signals supplied by the rotary axis and synchronously triggered, so possible defects on the wheel can precisely be localized. The measurement takes place at a resolution of ca. 30 µm, and a cloud comprising several millions of points are obtained.

Request for a quote

QUELLTECH GMBH

Germany

Four QuellTech Q6 3D- laser scanners are installed, mutually displaced by an angle of 90°. In this configuration, they are able to monitor the complete surface of the cable running through. It is important that the test does not lower the production speed, therefore very high sampling rates are required, supported by convenient data processing. The measured position of a defect is recorded in cable direction.

Request for a quote

QUELLTECH GMBH

Germany

The QS View software package is intended for dimensional control in 2D or 3D QS-View 2D / 3D software for all measuring tasks 3D representation of an irregular body for determination of volume and weight. With the 2D / 3D software a wide variety of parameters can be processed and displayed, e.g. length, width, angle height, gap, presence, volume (resp. weight), seam geometry (height, width), gap dimensions. Due to the modular structure of the software, customized specialties can be added any time. Each module delivers the results to an individual output module. The universal SPC interface allows simple connection to S7 controllers via Ethernet. 2D / 3D software developer kits are available for integrators with corresponding knowhow.

Request for a quote

QUELLTECH GMBH

Germany

Laser sensor Q4 – with a small form factor – Q4 for standard 2D / 3D measuring applications: Low sensitivity against influences of secondary light Measuring ranges from 5 mm to 1000 mm Laser wave lengths starting from UV via blue, red and green through to IR Average measuring speed up to 350 Hz frame The Q4 laser sensor has been designed to meet the requirements of standard measuring applications. Thanks to its increased flexibility, it can be used for several tasks also in complex projects. The dimensions of the ultra-compact version amount to only 86x40x25, at a weight of 140 g. Protective panes and cooling modules are available as an option. The Q4 laser sensor model enables users to obtain stable measuring results also on difficult surfaces, whether mirroring or transparent. The QS-View Standard Software comprises a comprehensive selection of application modules, to be invoked at once without previous programming steps. Customized adaptations are possible any time.

Request for a quote

QUELLTECH GMBH

Germany

Many materials cannot be measured tactilely, therefore non-contact thickness measurements become necessary. Especially e.g. with glowing materials, or wet processes, a continuous tactile measurement is nearly impossible. Furthermore, web speeds in plant engineering and production have increased, requiring a corresponding fast sampling rate of the measuring systems. In addition, high measuring widths are often required. Why is contact free measurement technology so perfect for this application? Can be used in any web width, Scalable measurement thicknesses from a few millimetres to several meters, Thickness and coating thickness can be measured for different materials, Vibrations of the web materials, can be compensated, Turnkey solution for mechanical engineering, Non-contact and non-destructive measurement method, Large distances to the measured object are possible, Measurement of free forms,

Request for a quote

QUELLTECH GMBH

Germany

The QuellTech laser sensor family Q4 or Q5 used for these tasks is generally mounted on an arm of a rotational axis, to scan along the complete 360° angle of the internal surface in a sequence of strips. The Q4 sensors can also be used to control the weld seam tracking itself for rapid setup and ease of use. Even during a project, the range and scope of the Q Series sensor demonstrates the advantages of a modular system to quickly adapt to project needs, where the smallest system has provided fast analysis of pipes as small as 105mm. The low power, with standard communication protocols, enable battery powered systems to transmit wireless data to other systems for review and cloud back up.

Request for a quote

MICRO-EPSILON

Germany

3D sensors from Micro-Epsilon are equipped with an easy-to-integrate SDK (Software Development Kit). The SDK is based on the GigE Vision and GenICam industry standards including the following function blocks: Network configuration and sensor connection Extensive sensor control Transmission control of measurement images Management of user-defined parameter sets C++ sample programs and documentation Access to the sensor via GigE Vision is also possible without SDK using a GenICam client.

Request for a quote

MICRO-EPSILON

Germany

The Industrial Performance Unit is a powerful computing platform for the efficient commissioning of Micro-Epsilon 3D sensors. The fully compatible controller is ideally suited to inline processes in 3D measurement tasks. The intuitive 3DInspect software with Valid3D technology enables simple and fast sensor parameter setting, which allows measurements to start immediately. The Industrial Performance Unit directly processes three-dimensional data, which is subsequently evaluated and assessed via the 3DInspect software. Results can be output via the integrated PROFINET, EtherCAT and EtherNet/IP interfaces.

Request for a quote

MICRO-EPSILON

Germany

3DInspect is a uniform and user-friendly software tool for all 3D sensors from Micro-Epsilon. Parameter setting of the 3D sensors and recording of the measurement data are done directly in the 3DInspect software. Powerful tools allow point cloud alignment and filtering, intuitive detection and selection of relevant areas, and program combination. The 3D point clouds can be processed as required and measured values can be output to the controller.

Request for a quote

MICRO-EPSILON

Germany

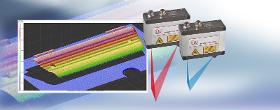

scanCONTROL 3D scanners are used for precise inline 3D measurements in numerous applications. Scans are performed by moving the scanner or the target. Due to their low weight, the scanners are ideally suited both for robotic applications and inline production monitoring. These 3D laser scanners are characterized by high dynamics, absolute precision and their compact size. With the scanCONTROL 3000 and the new scanCONTROL 3002 series, Micro-Epsilon offers a comprehensive portfolio with numerous measurement areas, Red and Blue laser technologies and extensive accessories. The scanCONTROL 3D laser scanners are based on the latest GigE Vision and GenICam standards and can therefore be integrated into a wide range of image processing environments. The powerful 3DInspect software is available for parameter setting, evaluation and output.

Request for a quote

MICRO-EPSILON

Germany

The reflectCONTROL RCS110-245 with integrated controller is designed for stationary measurements or integration into machines. This compact sensor detects anomalies on shiny surfaces which are processed and displayed as reflectivity and curvature image by software. GigE Vision enables the transfer of surface images to a wide range of image processing software packages for further analyses.

Request for a quote

MICRO-EPSILON

Germany

The high-precision surfaceCONTROL 3D 3500 snapshot sensor is used for automated optical inspection of geometry, shape and surfaces on diffusely reflecting surfaces. The surfaceCONTROL 3D 3500 is characterized by its compact design and high measurement accuracy combined with high speed data processing. With a z-axis repeatability of up to 0.4 µm, the sensor sets new standards in high-precision inline 3D measurement technology. It reliably detects the smallest flatness deviations and height differences. Two models cover different measuring fields.

Request for a quote

MICRO-EPSILON

Germany

surfaceCONTROL sensors are used for 3D measurements and surface inspections. The sensors use the fringe projection principle to detect diffuse reflecting surface and to generate a 3D point cloud. This point cloud is subsequently evaluated in order to recognize geometry, extremely small defects and discontinuities on the surface. Sensors with different measurement areas are available. This enables the inspection of the finest of structures on components as well as form deviations on large-area attachments. Powerful software packages are available for evaluation and parameter setting.

Request for a quote

MICRO-EPSILON

Germany

The surfaceCONTROL 3D 2500 snapshot sensor is used in 3D measurements for geometry, shape and surface inspection on diffuse reflecting surfaces. The sensor can be used in both automated in-line and at-line inspections as well as in the metrology room. The fringe light projection allows direct 3D measurement. The sensor is characterized by its large measuring field as well as a high measuring range depth of up to 300 mm with a repeatability of up to 3.0 µm. The captured images are transferred to the external controller where they are processed into 3D data. Three models cover different measuring fields.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

JUKI AUTOMATION SYSTEMS GMBH

Germany

Inspection of Surfaces 2D and 3D Regarding surface quality inspection for metal products such as cylinder head, gear tooth, it consumes a lot of time and human resources for the inspection. Since parts are inspected by bare eyes or slow speed inspection machines. With the inspection machine HE1000, inspection is much faster, more accurate and fully automated. In addition, there is a 3D laser sensor combined with our 2D inspection head to provide the most accurate result. This sensor is the first in the world to apply the Nobel Prize winning physics technology of optical frequency combs. It utilizes coaxial lasers and high precision range finders. There are some cases that our customers reduced over 90% of the inspection time. urthermore, if parts are inspected by humans, there might be different results by each person, because each of them has a different tendency and criterion.

Request for a quote

COGNEX CORPORATION

Germany

DSMax is the fastest and highest definition laser line 3D displacement sensor on the market for acquiring images and inspecting products in 3D. It is the only sensor that offers: — High scan rates (up to 18 kHz) at full measurement range — Maximum resolution images (2,000 profile points) — Fast high dynamic range (HDR) image These features make it the ideal solution for measuring and inspecting very small parts, such as electronic components, which can contain highly reflective or dark features.

Request for a quoteResults for

3d sensors - Import exportNumber of results

20 ProductsCountries

Company type