- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- 3d printers

Results for

3d printers - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

custom printer accessories for machining.

Request for a quote

VOXELJET AG

Germany

• Mold measurements up to 4 x 2 x 1 m • Does away with elaborate and expensive mold set-ups • Short throughput time (a few days) • Sand molds correspond 1:1 with CAD model • Structures can be designed in accordance with requirements, without having to watch for draft angles or undercuts • Special sands prevent casting problems • Surface quality can be adjusted through use of different sands • Coarse-grained sands for high gas permeability • Considerable flexibility with changes in geometry, without additional expenses • No storage or maintenance of patterns • Cost savings particularly for complex molds and batch sizes of 1 to several hundred pieces

Request for a quote

VOXELJET AG

Germany

• Mold measurements up to 4 x 2 x 1 m • Does away with elaborate and expensive mold set-ups • Short throughput time (a few days) • Sand molds correspond 1:1 with CAD model • Structures can be designed in accordance with requirements, without having to watch for draft angles or undercuts • Special sands prevent casting problems • Surface quality can be adjusted through use of different sands • Coarse-grained sands for high gas permeability • Considerable flexibility with changes in geometry, without additional expenses • No storage or maintenance of patterns • Cost savings particularly for complex molds and batch sizes of 1 to several hundred pieces

Request for a quote

VOXELJET AG

Germany

• Mold measurements up to 4 x 2 x 1 m • Does away with elaborate and expensive mold set-ups • Short throughput time (a few days) • Sand molds correspond 1:1 with CAD model • Structures can be designed in accordance with requirements, without having to watch for draft angles or undercuts • Special sands prevent casting problems • Surface quality can be adjusted through use of different sands • Coarse-grained sands for high gas permeability • Considerable flexibility with changes in geometry, without additional expenses • No storage or maintenance of patterns • Cost savings particularly for complex molds and batch sizes of 1 to several hundred pieces

Request for a quote

VOXELJET AG

Germany

• Mold measurements up to 4 x 2 x 1 m • Does away with elaborate and expensive mold set-ups • Short throughput time (a few days) • Sand molds correspond 1:1 with CAD model • Structures can be designed in accordance with requirements, without having to watch for draft angles or undercuts • Special sands prevent casting problems • Surface quality can be adjusted through use of different sands • Coarse-grained sands for high gas permeability • Considerable flexibility with changes in geometry, without additional expenses • No storage or maintenance of patterns • Cost savings particularly for complex molds and batch sizes of 1 to several hundred pieces

Request for a quote

VOXELJET AG

Germany

• Mold measurements up to 4 x 2 x 1 m • Does away with elaborate and expensive mold set-ups • Short throughput time (a few days) • Sand molds correspond 1:1 with CAD model • Structures can be designed in accordance with requirements, without having to watch for draft angles or undercuts • Special sands prevent casting problems • Surface quality can be adjusted through use of different sands • Coarse-grained sands for high gas permeability • Considerable flexibility with changes in geometry, without additional expenses • No storage or maintenance of patterns • Cost savings particularly for complex molds and batch sizes of 1 to several hundred pieces

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

– Volumetric printing system – Disposable caps with rotor and piston – For low to high viscosity biomaterials – Linear relation between dosing volume and rotation speed – Active suck-back prevents dripping or stringing of biomaterials – Precise start and end points – Low-maintenance and durable print heads – Easy integration into bioprinting machines – Driven by a 2-phase stepper motor – Luer-Lock connection for dispensing needles

Request for a quote

VOXELJET AG

Germany

• Model measurements up to 1.000 x 600 x 500 mm • Same handling as for conventional wax parts • Tool-less and hence more cost-effective process • Single items and small series can be produced within a few days • High degree of accuracy: ±0.4% (min. +/- 100 µm) • Wax infiltration creates closed smooth surface • Suitable for autoclaves, even for thin-walled shells • Can be burnt out in normal kiln with low emission formation • Does not expand during burn-out process, hence no shell cracking (whether gypsum or ceramics) • Residual ash contents <0.02% for polypor binder type C • All alloys can be used with lost-wax casting process

Request for a quote

VOXELJET AG

Germany

• Model measurements up to 1.000 x 600 x 500 mm • Same handling as for conventional wax parts • Tool-less and hence more cost-effective process • Single items and small series can be produced within a few days • High degree of accuracy: ±0.4% (min. +/- 100 µm) • Wax infiltration creates closed smooth surface • Suitable for autoclaves, even for thin-walled shells • Can be burnt out in normal kiln with low emission formation • Does not expand during burn-out process, hence no shell cracking (whether gypsum or ceramics) • Residual ash contents <0.02% for polypor binder type C • All alloys can be used with lost-wax casting process

Request for a quote

VOXELJET AG

Germany

• Model measurements up to 1.000 x 600 x 500 mm • Same handling as for conventional wax parts • Tool-less and hence more cost-effective process • Single items and small series can be produced within a few days • High degree of accuracy: ±0.4% (min. +/- 100 µm) • Wax infiltration creates closed smooth surface • Suitable for autoclaves, even for thin-walled shells • Can be burnt out in normal kiln with low emission formation • Does not expand during burn-out process, hence no shell cracking (whether gypsum or ceramics) • Residual ash contents <0.02% for polypor binder type C • All alloys can be used with lost-wax casting process

Request for a quote

VOXELJET AG

Germany

• Model measurements up to 1.000 x 600 x 500 mm • Same handling as for conventional wax parts • Tool-less and hence more cost-effective process • Single items and small series can be produced within a few days • High degree of accuracy: ±0.4% (min. +/- 100 µm) • Wax infiltration creates closed smooth surface • Suitable for autoclaves, even for thin-walled shells • Can be burnt out in normal kiln with low emission formation • Does not expand during burn-out process, hence no shell cracking (whether gypsum or ceramics) • Residual ash contents <0.02% for polypor binder type C • All alloys can be used with lost-wax casting process

Request for a quote

VOXELJET AG

Germany

• Model measurements up to 1.000 x 600 x 500 mm • Same handling as for conventional wax parts • Tool-less and hence more cost-effective process • Single items and small series can be produced within a few days • High degree of accuracy: ±0.4% (min. +/- 100 µm) • Wax infiltration creates closed smooth surface • Suitable for autoclaves, even for thin-walled shells • Can be burnt out in normal kiln with low emission formation • Does not expand during burn-out process, hence no shell cracking (whether gypsum or ceramics) • Residual ash contents <0.02% for polypor binder type C • All alloys can be used with lost-wax casting process

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

unprecedented opportunities thanks to newest 3D-print technology: whether ultra-stable up to 103°C/217,4°F heat-resistant plastic parts or elastical silicone up to 65 shore – we can meet your very special needs on a wide range – with a print resolution of up to 15 μm! Realizing ideas quickly: we print your prototypes, devices, models, sales samples, artworks or even final products made of plastics or silicone. For your individual 3d-print, we need your data-model in STEP- or STL-format. We are looking forward to your inquiries!

Request for a quote

VOXELJET AG

Germany

• Model measurements up to 1.000 x 600 x 500 mm • Same handling as for conventional wax parts • Tool-less and hence more cost-effective process • Single items and small series can be produced within a few days • High degree of accuracy: ±0.4% (min. +/- 100 µm) • Wax infiltration creates closed smooth surface • Suitable for autoclaves, even for thin-walled shells • Can be burnt out in normal kiln with low emission formation • Does not expand during burn-out process, hence no shell cracking (whether gypsum or ceramics) • Residual ash contents <0.02% for polypor binder type C • All alloys can be used with lost-wax casting process

Request for a quote

VOXELJET AG

Germany

The VX4000 is the world's biggest industrial 3D printing system for sand molds. It has a cohesive build space measuring 4,000 x 2,000 x 1,000 mm (LxWxH). This machine can be used to economically produce very large individual molds, a great many small series components or a combination of the two. With its uniquely large volume, the VX4000 maximizes productivity and flexibility. The unique and patented layering process was specially adapted for this printer. Instead of lowering the building platform during the printing process, the print head and coater are raised with each layer. As a result, the machine can bear the enormous weight of the building platform, which can be quickly exchanged via a rail—making it possible to print nearly continuously. Sand can be used as the particulate material. The VX4000's print head system can achieve a resolution of up to 300 dpi. A layer applied in one cycle is 300 µm thick.

Request for a quote

VOXELJET AG

Germany

The VX2000 is a 3D printer for industrial applications. It is a particularly good choice for cost-effectively producing large-format models from sand cores for prototyping. The VX2000 can also be used to economically manufacture small-series components. The machine is fast and easy to operate. The build space measures up to 2,000 x 1,000 x 1,000 mm. The VX2000's print head system can achieve a resolution of up to 300 dpi. A layer applied in one cycle is 300 µm thick.

Request for a quote

VOXELJET AG

Germany

Our international bestseller: the VX1000 is a universal 3D printer for industrial applications. The machine is fast, easy to operate and enables you to cost-effectively produce medium-sized molds, cores and models for making prototypes. The VX1000 is also suitable for producing small series. Plastic and sand can be used as the particulate material. The piezo print head system of the VX1000 achieves a resolution of up to 600 dpi. The machine's build space measures 1,000 x 600 x 500 mm. The thickness of a layer applied in one cycle is 150 µm for plastic and 300 µm for sand. In addition, the VX1000 concept is environmentally friendly: In plastic processes, the unprinted particulate material is recyclable.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

VOXELJET AG

Germany

The VX200 is the most compact 3D printer in the voxeljet portfolio. It weighs a mere 450 kilograms and, thanks to its dimensions of only 1,700 x 900 x 1,500 mm (LxWxH), the VX200 can be installed without problems in places where space is tight, such as research laboratories. The machine is very fast, easy to operate and permits the economical production of small prototypes and design pieces. Plastic and sand can be used as the particulate materials. The build space measures 300 x 200 x 150 mm. The VX200's print head system can achieve a resolution of up to 300 dpi. The thickness of a layer applied in one cycle is 150 µm for plastic and 300 µm for sand.

Request for a quote

ZANDER GMBH

Germany

We use Stratasys Dimension Elite printers, the high-strength ABSplus plastic in the FDM process. With our Agilista from Keyence we are able to print acrylic and silicone in the inkjet process. These components are known to be accurate, stable and durable in their dimensions. They retain their tolerances over time without warping, shrinking or attracting water. Climatic influences do not change the dimensions of the built parts. Acrylic components can then be machined mechanically. Possible applications: display model architecture model functional devices prototypes functional model Ergonomic studies Gauges and devices promotional Requirement: A record in the format STEP, CATIA, IGES or STL

Request for a quote

TANGIBLE ENGINEERING GMBH

Germany

Size: 40x28x58cm Benefits: - Rapid Cure 10-35 minutes depending on material - Cure large objects up to 346 mm x 195 mm x 400 mm - Maximum throughput with flexible positioning Technical Features: - 76 High Power LEDs for uniform 360 degree post cure - 3 Special Coated Glas Plates with flexible positioning - High Reflection Materials - Long Lifetime LEDs - Touch Display - Safety Controls - Active Cooling - Wavelength 405 nm

Request for a quote

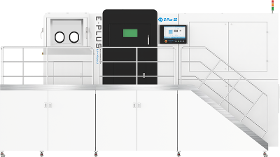

EPLUS3D TECH GMBH

Germany

EP-M150Pro adopts patented MPBF™(Metal Powder Bed Fusion)to produce high performance, high accuracy and high details parts at large scale. The machine is capable of optional single/dual laser system, and 200/500W laser source for different production requirements. The available materials are Aluminum alloy, Titanium alloy, Inconel alloy, Maraging steel, Stainless steel, CoCr, Copper alloy and so on.

Request for a quote

EPLUS3D TECH GMBH

Germany

With Eplus3D MPBF™(Metal Powder Bed Fusion) technology, EP-M150 can professionally print complex 3D geometry data into high-performance metal 3D parts which are suitable for batch manufacturing of dental parts medical implants and material research centers to develop various metal powders with its open parameter platform.

Request for a quote

EPLUS3D TECH GMBH

Germany

With a building chamber size of 456*456*1080 mm³, Eplus3D Introduces EP-M450H to the successful line of MPBF 3D printers. The new EP-M450H is a marvelous metal printer that makes the production of reliable and high quality large metallic parts viable on industrial scale without requiring any tools.

Request for a quote

EPLUS3D TECH GMBH

Germany

With a building chamber size of 455*455*500mm Eplus3D Introduces EP-M450 to the successfulline of MPBF™ 3D printers. The complete open systemmakes EP-M450 a very powerful tool for large scaleproduction for our customer to access different metal powders like titanium, aluminum, nickel alloys and stainless steel, etc. EP-M450 is aiming to output the large parts with its high performance and high accuracy.

Request for a quote

EPLUS3D TECH GMBH

Germany

Using MPBF (Metal Powder Bed Fusion) technology, the EP-M650 is using a 655x655x800mm3 build envelope and quad laser systems to ensure a high efficiency production. The precise positioning and innovative area splicing control technology offers uniformity and stability throughout the whole printing phase. The system can operate with various metal powders such as Titanium, Aluminum and Nickel-based alloys, Maraging Steel, Stainless Steel, Chrome Cobalt Alloys and other materials. It is suitable for the direct manufacturing of large-size, high-precision and high-performance parts in the aerospace, aviation, automotive and defense industry.

Request for a quote

IGUS® GMBH

Germany

igus® presents world's first tribological 3D filament for 3D printers. The tribological 3D printing material is up to 50 times more abrasion-resistant than conventional 3D print materials igus® has been researching the 3D printer filament field to provide its customers with even more flexibility. Real useable parts can now be produced for prototyping. At the moment we offer two materials: the highly wear resistant iglidur® I170-PF and the flexible iglidur® I180-PF. igus®' 3D printer material starter kits are now available in weights from 25 g and diameters of 1,75 mm - 3 mm. Typical applications:Prototype construction, small batches, test installations Delivery program: Delivery program: Wear linear: v= 0,1 m/s; p= 1 MPa; l= 5 mm Wear pivoting: v= 0.01 m/s; p= 1 MPa; ß= 60 igus® presents world's first tribological 3D filament for 3D printers. The tribological 3D printing material is up to 50 times more abrasion-resistant than conventional 3D print materials igus® has been researching the 3D printer filament field to provide its customers with even more flexibility. Real useable parts can now be produced for prototyping. At the moment we offer two materials: the highly wear resistant iglidur® I170-PF and the flexible iglidur® I180-PF. igus®' 3D printer material starter kits are now available in weights from 25 g and diameters of 1,75 mm - 3 mm. Typical applications:Prototype construction, small batches, test installations igus® presents the first tribo filament for 3D printers The new 3D printing materials are up to 50 times more abrasion-resistant than conventional 3D print materials. Complete processing instructions for iglidur® I170-PF (PDF) Complete processing instructions for iglidur® I180-PF (PDF) iglidur® |180-PF Hotend temperature: 220 - 250 °C Bed temperature: 90 - 110 °C Excellent wear behaviour Material table Colour white Moisture absorption at 23 °C and 50 %r.h. 0,3 weight-% Max. water absorption 0,9 weight-% Max. long term application temperature +80 °C Max. short term application temperature +90 °C Minimum application temperature -40 °C Delivery program: iglidur® |170-PF Hotend temperature: 220 - 250 °C Bed temperature: 90 - 110 °C Outstanding wear behaviour of the tribo filaments Harder to process Material table Colour yellow Moisture absorption at 23 °C and 50 %r.h. 0,5 weight-% Max. water absorption 1,6 weight-% Max. long term application temperature +75 °C Max. short term application temperature +85 °C Minimum application temperature -40 °C Delivery program: Y = rate of wear [µm/km] * moulded Wear linear: v= 0,1 m/s; p= 1 MPa; l= 5 mm Y = rate of wear [µm/km] * moulded Wear pivoting: v= 0.01 m/s; p= 1 MPa; ß= 60

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Maximize performance for your 3D printer Porex creates a wide variety of standard and custom solutions including diffusers, air & liquid filters, wicks, vents and absorptive media to meet your 3D printing needs. Specifically designed for 3D printers, our broad portfolio of porous media solutions can meet virtually any challenging application need. request sample ask an engineer

Request for a quote

MICRO-EPSILON

Germany

The optoNCDT 1220 is the entry-level model for precise measurements in industrial automation. This compact laser triangulation sensor measures displacement, distance and position with high precision. Based on an excellent price/performance ratio, this sensor is ideally suited to measurement tasks involving a large number of pieces. Therefore, the sensor can be used in all fields of automation technology, e.g., in machine building, 3D printers or robotics.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

Additive manufacturing processes are a great alternative to classical processing techniques and aim at a constructionally optimized and cost-effective production of components. 3D printing now includes a variety of technologies that can be used in different 3D printer versions. ViscoTec uses established dosing systems with the endless piston principle specifically for 3D printing of viscous fluids and pastes. And it creates new possibilities for printing 1-component viscous fluids and pastes.

Request for a quoteResults for

3d printers - Import exportNumber of results

41 ProductsCountries