- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- 3d lasers

Results for

3d lasers - Import export

ZOLLER & FRÖHLICH GMBH

Germany

Based on the high quality laser scanner Z+F IMAGER®, Zoller + Fröhlich GmbH and DMT GmbH & Co. KG have developed an explosion proof 3D laser scanner. The Z+F IMAGER® 5006EX pioneers surveying in underground mining and industries where explosive atmospheres occur. The Z+F IMAGER® 5006EX is the world´s first ATEX approved 3D laser scanner for use in mining and industrial applications under explosive conditions.The Z+F IMAGER® 5006EX is class I and class II approved according to ATEX directive 94 / 9 / EG. The ATEX directive 94 /9 / EG "Equipment and protective systems intended for use in potentially explosive atmospheres" is a European standard. The ATEX approval for this equipment is widely accepted outside the European community as well.

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

The terrestrial 3D laser scanner Z+F IMAGER® 5016A combines compact and lightweight design with state-of-the-art 3D laser scanning surveyor technology - allowing the user to reach new levels. It's equipped with an integrated HDR camera, internal lighting and positioning system. All components of the terrestrial 3D laser scanner have been further developed and adjusted to the new design, resulting in even better scanning results and a more efficient workflow. With feature A, which stands for Advanced, the 5016 receives twice as high scan rate of up to 2.187 million pixels/second and more options for leveling the scanner. If the dynamic compensator is deactivated or the tilt is outside the defined range, the tilt is detected by the IMU of the Z+F IMAGER® 5016A.

Request for a quote

QUELLTECH GMBH

Germany

Particular Challenge: For the assessment of rotating parts, numerous parameters have to be taken into consideration: Concentricity, radial run-out and axial run-out (i.e. wobble); furthermore thickness, diameter, planarity and the absence of surface defects had to be examined. The solution developed by QuellTech consists in a configuration of three Q6 Laser Laser Scanners.Each of the lateral surfaces is assigned to its own scanner. In order to enable the thickness precisely to be determined, both laser lines are mutually oriented in opposite direction. The third scanner inspects the outer circumference of the wheel, this way measuring diameter and radial run-out. All of these scanners are subject to encoder signals supplied by the rotary axis and synchronously triggered, so possible defects on the wheel can precisely be localized. The measurement takes place at a resolution of ca. 30 µm, and a cloud comprising several millions of points are obtained.

Request for a quote

QUELLTECH GMBH

Germany

Particular Challenges of the Application: By tactile equipment, determination of the deepest point on a rough metal surface is neither simple or precise. As a consequence, often either too much material is removed, or the surface is still covered with defects which have to be eliminated by a following milling cycle. The equipment is arranged in parallel, so that the complete width of the slabs is covered. The sensors are calibrated to a common coordinate system and mounted on a movable gantry. Before measurement, the slabs are fixed in place. The scanners mounted on the gantry are guided over the measuring object, driven by an electric motor. The point cloud recorded by the four scanners is consolidated in a PC by means of the QuellTech image processing software which calculates the difference between highest and lowest point of the corresponding surface and compensates for possible inclination of the slab (detrending).

Request for a quote

QUELLTECH GMBH

Germany

The QS View software package is intended for dimensional control in 2D or 3D QS-View 2D / 3D software for all measuring tasks 3D representation of an irregular body for determination of volume and weight. With the 2D / 3D software a wide variety of parameters can be processed and displayed, e.g. length, width, angle height, gap, presence, volume (resp. weight), seam geometry (height, width), gap dimensions. Due to the modular structure of the software, customized specialties can be added any time. Each module delivers the results to an individual output module. The universal SPC interface allows simple connection to S7 controllers via Ethernet. 2D / 3D software developer kits are available for integrators with corresponding knowhow.

Request for a quote

QUELLTECH GMBH

Germany

The new QuellTech Q5 Laser Scanner Series combines the advantages of small form factors with both high resolution and scan rate. The sensor disposes of different set-up possibilities with respect to the analysis algorithm. Measurement results are delivered via Ethernet, calibrated in the X / Z plane. Special adjustable algorithms can be selected, extremely useful particularly also for optically most demanding surfaces. Time-consuming calibration tasks for the user are no more required, as the calibration routine runs on board. High Scan Rate with up to 14,000 Profiles per Second Due to an appropriate limitation of the image range (AOI) in X and Z direction, the scan rate could considerably be increased. High resolution and detection frequency with up to 14.000 profiles and 28 Mio. points per second •X measuring range from 10 to 1022 mm •Z measuring range (height) from 5 to 878 mm •Laser wave length blue 405/450nm, red 650nm

Request for a quote

QUELLTECH GMBH

Germany

The QuellTech laser sensor family Q4 or Q5 used for these tasks is generally mounted on an arm of a rotational axis, to scan along the complete 360° angle of the internal surface in a sequence of strips. The Q4 sensors can also be used to control the weld seam tracking itself for rapid setup and ease of use. Even during a project, the range and scope of the Q Series sensor demonstrates the advantages of a modular system to quickly adapt to project needs, where the smallest system has provided fast analysis of pipes as small as 105mm. The low power, with standard communication protocols, enable battery powered systems to transmit wireless data to other systems for review and cloud back up.

Request for a quote

QUELLTECH GMBH

Germany

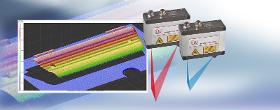

Many materials cannot be measured tactilely, therefore non-contact thickness measurements become necessary. Especially e.g. with glowing materials, or wet processes, a continuous tactile measurement is nearly impossible. Furthermore, web speeds in plant engineering and production have increased, requiring a corresponding fast sampling rate of the measuring systems. In addition, high measuring widths are often required. Why is contact free measurement technology so perfect for this application? Can be used in any web width, Scalable measurement thicknesses from a few millimetres to several meters, Thickness and coating thickness can be measured for different materials, Vibrations of the web materials, can be compensated, Turnkey solution for mechanical engineering, Non-contact and non-destructive measurement method, Large distances to the measured object are possible, Measurement of free forms,

Request for a quote

QUELLTECH GMBH

Germany

Q6-Lasor sensor – High Speed, High Resolution – Q6 Sets New Standards for 2D / 3D Measurement: Resolution of up to 0.6 µm Profile speed of up to 25.000 profiles/s Measuring ranges between 2 mm and up to 370 mm available Laser wave lengths starting from UV via blue, red and green through to IR The Q6 laser sensor series has already proven its ability in numerous industrial applications demanding a high degree of precision and process stability at increased travel speed. For common environments, connection is established via GIGE interface and GeniCam. Integration with linear axes and robots is possible by means of encoder inputs and trigger option.

Request for a quote

QUELLTECH GMBH

Germany

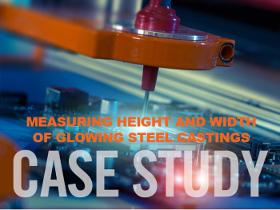

Laser Scanner Solution: This task is a typical application of the high-resolution QuellTech 2D/3D Q5-880 Blue Laser Scanners. Two of these units are placed at the left and at the right of the measuring objects, at a defined inclination angle. Blue laser light in this case is a prerequisite, as the cast parts are red-hot, hence emitting in the red spectral range. Additionally, the client was in need of a software solution for the project, so a 3D point cloud processing application was implemented, performing inline and evaluating width, height and angle results. QuellTech customer is able to inspect continuously the product quality, simultaneously avoiding scrap. He uses the same system for more than 10 different types of castings. Errors caused by manual inspection are considerably reduced, and safety for personnel is enhanced.

Request for a quote

QUELLTECH GMBH

Germany

Laser sensor Q4 – with a small form factor – Q4 for standard 2D / 3D measuring applications: Low sensitivity against influences of secondary light Measuring ranges from 5 mm to 1000 mm Laser wave lengths starting from UV via blue, red and green through to IR Average measuring speed up to 350 Hz frame The Q4 laser sensor has been designed to meet the requirements of standard measuring applications. Thanks to its increased flexibility, it can be used for several tasks also in complex projects. The dimensions of the ultra-compact version amount to only 86x40x25, at a weight of 140 g. Protective panes and cooling modules are available as an option. The Q4 laser sensor model enables users to obtain stable measuring results also on difficult surfaces, whether mirroring or transparent. The QS-View Standard Software comprises a comprehensive selection of application modules, to be invoked at once without previous programming steps. Customized adaptations are possible any time.

Request for a quote

QUELLTECH GMBH

Germany

Four QuellTech Q6 3D- laser scanners are installed, mutually displaced by an angle of 90°. In this configuration, they are able to monitor the complete surface of the cable running through. It is important that the test does not lower the production speed, therefore very high sampling rates are required, supported by convenient data processing. The measured position of a defect is recorded in cable direction.

Request for a quote

QUELLTECH GMBH

Germany

A client in automotive industry intends to improve the inline glue bead supervision performed when automatically applying glue beads inside body parts. The system to be purchased should be able to monitor position, height and width of the glue bead any time. Until now, the client makes use of a 3D laser system with very complex beam guidance, in order to compensate problems arising from narrow space available. This present configuration however involves difficulties in adjustment, often giving rise to trouble and interruptions. Therefore the client is looking for a safe and less complicate solution. The chellenge in glue bead supervision: While the glue bead is being applied, very complex geometrical patterns are followed; the nozzle for the glue meanwhile does not rotate. Therefore this nozzle must be supervised in the total angle of 360°. This glue bead supervision can only be met by a laser scanner featuring an extremely low form factor.

Request for a quote

QUELLTECH GMBH

Germany

Testing requirements for a manufacturer in electronics industries had changed: For an assembly included in a smartphone, the absence of contact between speaker ultra fine wires and adjacent components is essential. Fulfillment of this condition, until now only subjected random sampling by microscopy, from now on has to be verified in a 100% procedure. Due to labor cost, microscopy for this amount of inspection is no more lucrative. Detection of ultra fine wires in electronic device The particular challenge The fine wires made of copper in smartphone speakers dispose of a high reflection and only a small diameter. The QuellTech Solution A high-resolution QuellTech 2D/3D Q4-5 Laser, featuring a particularly adapted laser wavelength and an ultrafine laser line in the corresponding installation, is combined with a linear axis equipped with a convenient encoder output. Due to its special chip analysis, the Quelltech sensor delivers a stable and highly reproducible signal on the fine wires

Request for a quote

MICRO-EPSILON

Germany

scanCONTROL 3D scanners are used for precise inline 3D measurements in numerous applications. Scans are performed by moving the scanner or the target. Due to their low weight, the scanners are ideally suited both for robotic applications and inline production monitoring. These 3D laser scanners are characterized by high dynamics, absolute precision and their compact size. With the scanCONTROL 3000 and the new scanCONTROL 3002 series, Micro-Epsilon offers a comprehensive portfolio with numerous measurement areas, Red and Blue laser technologies and extensive accessories. The scanCONTROL 3D laser scanners are based on the latest GigE Vision and GenICam standards and can therefore be integrated into a wide range of image processing environments. The powerful 3DInspect software is available for parameter setting, evaluation and output.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

RSLD is our short cut for a laser head consisting of a total of 3 motorized axes for use in large-format laser machines in gantry design for the 3-dimensional laser cutting of components. The horizontal main axis of the laser head permits endless movement, even during the rotary movement the axes below are permanently supplied with cooling water, process gases and all electrical signals. Suitable optics are used for the laser source used, either directly water-cooled metal mirrors with low-absorption coating or alternatively glass optics. The use of an adaptive optics enables the freely programmable focus position for cutting and piercing. The exclusive use of torque motors reduces mechanically moving components and thus guarantees consistently high machining accuracy and best machining results over a long service life, against mechanical damage reliably protects our proven 3D collision protection.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

RSD is our short name for a laser head consisting of a total of 2 motorized axes for use in large-format laser machines in gantry design for 3-dimensional laser cutting / laser welding of components. The horizontal main axis of the laser head permits endless movement, even during the rotary movement the axes below are permanently supplied with cooling water, process gases and all electrical signals. Suitable optics are used for the laser source used, either directly water-cooled metal mirrors with coatings of least absorption, or alternatively glass optics. The use of an adaptive optics optionally allows the freely programmable focus position for cutting and piercing. The exclusive use of torque motors reduces mechanically moving components and thus guarantees consistently high machining accuracy and best machining results over a long service life, against mechanical damage reliably protects our proven 3D collision protection.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SCHULZ STANZTECHNIK GMBH

Germany

Laser cutting parts and bending parts: Your special production in good hands. As part of the Schulz Group, Schulz Stanztechnik can also offer you – as a service and in addition to the stamping program – special laser cut parts in various materials and thicknesses. In accordance with your drawings, you will receive a meaningful offer from us within three working days, and your laser parts within ten working days of your order. Manufacture of 2D and 3D laser parts made of the most diverse of materials as well as angles in accordance with your drawings and specifications.

Request for a quote

RONIX GMBH

Germany

Before purchasing a product, most consumers frequently ponder what is the best laser level out there. But first, you need to consider a few things, the most crucial of which is what application and type of work site you want to utilize it for. Because it is preferable to use some of these measuring tools indoors as opposed to outdoors, such as 3D laser levels. RH-9536 is one of the several 3D laser levels that Ronix offers. It can be applied both vertically and horizontally. This 3D laser level is as accurate as it can be thanks to a self-leveling system that automatically corrects for small angular misalignments of ± 3°. A locking mechanism is installed to reduce vibration when shifting the tool to another location. This tool’s body design eliminates the possibility of harm in case of a fall or stroke thanks to its sturdy over-molded housing and ergonomic construction. See the detailed description section of this 3D Laser Level for additional features

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

The terrestrial 3D laser scanner Z+F IMAGER® 5016 combines compact and lightweight design with state-of-the-art 3D laser scanning surveyor technology - allowing the user to reach new levels. It's equipped with an integrated HDR camera, internal lighting and positioning system. All components of the terrestrial 3D laser scanner have been further developed and adjusted to the new design, resulting in even better scanning results and a more efficient workflow. Dimensions Usable in smallest spaces Carry-on luggage size Weight Laser scanner without battery: ≤ 6,5 kg (14.3 lbs) Laser scanner with 2 batteries: ≤ 7,5 kg (16.5 lbs) Ideal weight for stable setup Makes field work easier

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

Highly accurate measurement results require static scans from multiple angles, whereas mobile solutions focus on efficiency. The Z+F FlexScan® platform developed by Zoller + Fröhlich combines the advantages of static scans with the efficiency of mobile systems. The perfect complement for any time-sensitive or large-scale application: AEC, facilitiy management, process industries, heritage documentation and forensics. + Universal mounting The Z+F FlexScan® 22 is highly versatile and can be easily used with various support systems. This SLAM platform can be attached to backpacks, tripod carts, fixed tripods, and robots. Thanks to the Quick Mount System, switching between support systems can be done in just a few minutes. Furthermore, data captured with different support systems can be effortlessly registered in Z+F LaserControl®.

Request for a quote

RONIX GMBH

Germany

Most customers may wonder What is the most common measuring tool, before buying it. But first, you need to consider a few things, the most crucial of which is what application and type of work site you want to utilize it for. Because it is preferable to use some of these measuring tools indoors as opposed to outdoors, such as 3D laser levels

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

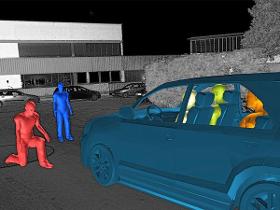

Within a few minutes, Z+F 3D laser scanners can provide accurate measurement data of crime scenes and accidents – indoors and outdoors. This data speeds up the investigation process by "freezing" the scanned crime scene and documenting it. These evaluations are accepted in court. Accident investigation The phase based 3D laser scanners of Z+F enable an accurate three-dimensional capturing of complete accident scenes with all the details like deformations of the vehicles or skidmarks. Using this technology, the question of the possible causes and sequence of the accidents can be analysed and answered more easily. Crime scene investigation The complete securing of evidence at crime scenes and the geometry measurement on the spot are of great importance. A crime scene is normally captured from various positions by the Z+F IMAGER®. By combining these scans, the viewer gets an overview of the complete scene.

Request for a quote

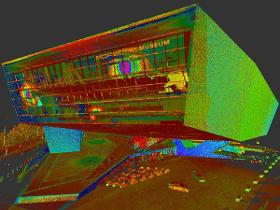

ZOLLER & FRÖHLICH GMBH

Germany

For listed buildings, there are regular new construction tasks. Often there are no adequate plans on the basis of which planning, modernization or renovation can be carried out. Due to the very high scan rate of more than 1 million measured values per second, range resolution in the millimeter range and a measuring accuracy in the mm range, even the capture of the finest structures and details is still possible with the 3D laser scanners from Zoller + Fröhlich. The 3D documentation is therefore the ideal prerequisite for reconstructions of, for example, design conditions or sensitive stucco work. The recorded inventories, damage, structures and details are recorded in databases and allow a faithful reconstruction of the entire object or of parts of the object at any later time.

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

Z+F 3D phase based laser scanners enable a detailed condition and damage assessment. Due to the high sampling rate as well as a range resolution of less than 1mm and a measurement accuracy of millimetres, even the most delicate structures and details can be documented. The surveyed status, damage, structures and details are stored in a database which allows the reconstruction of the complete object or parts of the object at any given time in the future.

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

In many projects insurance companies have the problem that the building to be insured is either not completely documented or was documented a long time ago, so that the available data is out of date. 3D laser scanning is an efficient way to detect the current condition of the building and all its details. The 3D data is particularly useful for insurance companies when it comes to the following tasks: Assessment of property value Surveying the inventory in 3D Calculation of areas In fact the 3D data is of particular importance in the case of damage. A new survey of the damaged object can be carried out and by using software, the condition before and after the damage can be compared and visualised directly. The amount of damage can be quantified much more precisely in comparison to a quantification without the use of 3D data.

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

Z+F 3D phase based laser scanners enable a detailed condition and damage assessment of the current status of a building or complex structure and its surroundings. It is easy to create 2D floor plans or views of the object to plan building or conversion projects of the 3D data. Therefore, 3D data is an ideal planning basis for structural measures. For site measuring, 3D documentation is just the right technology, because you will save time and money. Moreover you can evaluate different options of how the available rooms can be used without accessing the site in reality. The whole work can be done from your office desk and the data will be available even after many years. Structural damages Structural damages always mean economic loss for the owner and user of a building, and can influence the future value of a property significantly.

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

LFM Modeller With LFM Modeller, users can create intelligent 3D models of existing laser scan data and export the models to a variety of 3D CAD systems, with some few clicks. LFM NetView LFM NetView is a web-based application suitable for engineering and asset management. The application is available either as a standalone application or as a web browser plug-in, allowing free, secure access to huge databases with an unlimited number of scans. LFM Server With LFM Server, users can access and work with pre-registered 3D laser scan data, compare the planned design with existing data, and use CAD packages from AVEVA, Autodesk, Bentley, or Intergraph. LFM Gateway LFM Gateway provides a unique connection to terrestrial 3D scanners. The application can import data from mobile, handheld or airborne laser scanning.

Request for a quote

ALPHA LASER GMBH

Germany

Design and geometry freedom withh high material yield. With its unique cartridge concept, the 3D metal printer AL3D-METAL offers safe powder management and quick powder change. The new system AL3D-METAL makes it easy to get started in additive manufacturing. The processor does not come into contact with the powder. Also ideal for schools and universities. The intelligent cartridge knows which powder it is filled with and provides the right process parameters. However, if the processor likes to experiment, he has full control over the parameters. Its floor print is only 60 x 60 cm

Request for a quoteResults for

3d lasers - Import exportNumber of results

44 ProductsCountries

Company type

Category

- 3D scanner (14)

- 3D software (10)

- Laser - cutting and welding machines (8)

- Machine vision system (7)

- Sensors (6)

- 3D printers (5)

- Light-emitting diode LED (3)

- Measurement - Equipment & Instruments (2)

- Surface inspection systems (2)

- Tools, pneumatic (2)

- Bending machine tools (1)

- Dentistry - products (1)

- Foundry machines - centrifugal (1)

- Measurement equipment and instruments - position and distance (1)

- Optical measuring equipment (1)

- Printers - computer (1)