- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- gear teeth

Results for

Gear teeth - Import export

NORELEM FRANCE

France

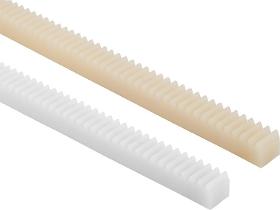

Injection moulded, straight teeth. Engagement angle 20°. Polyacetal, white. Polyketone, ivory tone. Note Polyacetal Standard material with high hardness grade and low coefficient of friction. Polyketone Material with significantly longer service life, higher power transmission and greater security against tooth breakage due to the extraordinarily high wear resistance and very good tribological properties. Can be used under water and other media. Due to the material properties, plastic gear racks are not straightened. L= nominal length 250 mm. The actual length is roughly a whole multiple of the pitch.

Request for a quote

NORELEM FRANCE

France

Milled toothing, straight teeth. Engagement angle 20°, bright. Note The gear racks are suitable for mounting in series.

Request for a quote

NORELEM FRANCE

France

Milled toothing, straight teeth. Engagement angle 20°, bright. Note Up to 48 teeth with hub one side, from 50 teeth supplied as disc form. The spur gears have a centre bore or pilot hole (this can vary due to manufacturing methods). For this reason, the dimension D2 max. given in the table is the maximum diameter of the bore with which the spur gears are supplied. This pilot/centre bore can be amended by the customer to produce a reamed bore, reamed bore with keyway or a tapped hole. Alternatively, customers can also use bushes to reduce the bore diameter. Form A with hub Form B without hub

Request for a quote

NORELEM FRANCE

France

Milled toothing, straight teeth engagement angle 20°, bright. Outside diameter extruded, tolerance h9. Note The gear rack teeth are cut using a hob mill. This results in minus tolerances for dimensions H and H1 up to module 2 0.2 mm. module 2.5 to 3 0.3 mm.

Request for a quoteREICH-KUPPLUNGEN ; DIPL.-ING. HERWARTH REICH GMBH

Germany

The ArcuDent tooth coupling is a double-jointed steel coupling. The teeth of the hubs and covers receive shape corrections to allow the highest misalignment capacity. It is a flexible, but nonetheless torsion-resistant coupling. The most important characteristics and advantages of ArcuDent tooth couplings: Special Shape of tooth in order to limit noise and vibrations interferences Ring Gear: Gear Teeth optimized by finite elements Tightness with standard o-rings that guarantee the long life of couplings Special gear teeth realized in order to increase the contact surface and to limit the superficial pressure Gear Hub: Bore hub capacity up to 800 mm optimization by finite elements Grade 12.9 screws allow for force-locking torque transmission EX-safety according to ATEX-standards We are glad to see that you are interested in our product line and are happy to answer all questions! Please use our contact form or call us: +49 234 959160. For additional information regarding designs,...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ILK IHRACAT AS.

Turkey

Gear manufacturing consists of the following basic steps: Material selection: Various materials, such as steel, aluminum, plastic, or others, can be used in gear manufacturing. Material selection is made according to the purpose of the gear. Gear profile design: The gear profile is designed Gear mold production: The gear mold is produced according to the gear profile. Gear production: The gear is produced using the selected method. Gear inspection: The gear is inspected after production. Get a Quote Now Contact us immediately for the most suitable production solutions for your gear needs. Our professional team is ready to provide you with exclusive offers. Who Are We: Steeling.Net carries out partner marketing activities in the Turkish metal industry. Our partner manufacturers are companies that specialize in sheet and steel processing and have a wide product range.

Request for a quote

ITALGEAR SRL

Italy

Cylindrical ground gears are cut by hobbing machines of the latest generation and finished by Reischauer and Gleason CNC grinding machines equipped with automatic loaders and special software that allow the correction of the twisting errors that may occur in helical gear and, with special ground cycles strategy minimizing noise of gears in operation. ITALGEAR can also make the finishing of the gears after carburizing heat treatment adopting the Skiving technology, which allows the precise finishing of gears through superfinishing of the teeth with a hard metal PVD coated hobs. The technology allows production of groundquality precise gears while reducing cutting time and costs effective at the same time. On request, ITALGEAR engineers can team up with the Customer R&D and suggest any appropriate measures to optimize the gear meshing in order to obtain low noise in operation.

Request for a quote

KB SCHMIEDETECHNIK GMBH - A GERMAN DROP FORGE - CLOSED DIE FORGINGS - ALL STEEL GRADES

Germany

Gears are mechanical components and an essential part of many machines and are used in everything from piston engines to gearbox construction to agricultural machinery and wind turbines. Main gear types are: Spur and Pinion Gears: These gears have straight teeth and are the most common. They transmit rotational movements parallel to the axis and are found in gears, clocks and machines. Bevel Gears: These gears have tapered teeth and movement between non-parallel axes. They are used in differential gears of vehicles and in industrial machinery. Worm Gear: This combination of worm and worm wheel provides high gear ratio and is used in hoists, conveyors and other applications. Hydraulic The West German drop forge KB Schmiedetechnik GmbH produces forged gear blanks, piston parts and hydraulic components for a wide range of applications - from agricultural machinery and conveyor technology to engine construction, diesel generators to shipbuilding.

Request for a quote

VESTA PETROKIMYA URUN. VE ENERJI SAN. TIC. LTD. STI.

Turkey

RX80 Gear Oil stands as a cutting-edge manual transmission fluid meticulously engineered to deliver smoother gear transitions across a broad spectrum of temperatures. It is compatible with the manual transmissions found in numerous vehicle models from various manufacturers. Notably, RX80 Gear Oil exhibits exceptional adaptability in cold climates. It minimizes the resistance during initial use, while also effectively managing transmission noise and idling vibrations during regular operation. RX80 Gear Oil provides: Reduced transmission noise for quieter operations. Effortless shifting in low temperatures. Enhanced longevity of gear teeth and bearings. Consistent lubrication performance across a wide range of operating temperatures. Exceptional wear resistance, ensuring a strong and protective film throughout the lubricant’s lifespan. Minimal friction in 2-stroke motorcycle gearboxes.

Request for a quote

VESTA PETROKIMYA URUN. VE ENERJI SAN. TIC. LTD. STI.

Turkey

Roadranger SAE 50 is a mineral oil-based lubricant designed for a wide range of applications, including Roadranger gearboxes, as well as automotive and industrial uses that do not require extreme pressure resistance. Thanks to its high viscosity index and low pour point, this lubricant forms a robust and highly adhesive film to safeguard gear teeth and bearings against wear. When the manufacturer recommends API service GL-1 or GL-2 gear oil, Roadranger SAE 50 is a suitable choice. It is also ideal for lubricating various manual transmissions in mild gear oil applications, as well as for use in some spiral bevel axle assemblies and worm gear drives found in commercial, agricultural, and truck equipment

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

High braking torque and small installation space: The compact and powerful BFK464-R dual-circuit spring-applied brake from INTORQ does it economically. This brake works with a split armature plate and two independent coil circuits. It reliably complies with the legal requirements for redundancy, such as for use in passenger elevators. In addition to the reliable braking torque, the high switching dynamics add even more safety. Switching noises are kept to a minimum. This is achieved by the well-engineered damping system. Another plus is the compact design: The rotor neck only minimally protrudes into the motor bearing shield, and the gear teeth of the rotor are particularly short.

Request for a quote

NEUGART GMBH

Germany

The integrated gearbox/pinion combination provides the best technical coordination for rack and pinion drives. Numerous solution options provide high dynamics and high load-bearing capacities at the same time because of the precision gearing Thanks to its spiral teeth, our WPLN achieves the optimal synchronism for the best surface qualities. By minimizing vibrations, it runs uniformly and quietly. The precision right angle planetary gearbox features lifetime lubrication and can be mounted virtually anywhere.

Request for a quoteResults for

Gear teeth - Import exportNumber of results

13 ProductsCountries

Company type