- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- gear technology

Results for

Gear technology - Import export

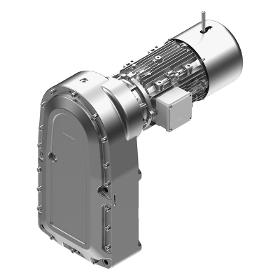

PGR DRIVE TECHNOLOGIES

Turkey

PCS series gear units of PGR Drive Technologies serving up to 60 tones of capacity are optimum solution partners for crane industry thanks to their silent, compact bodies and easy maintenance features.

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

Gear hobbing on CNC lathes without B-axis Years ago, EWS was the first tool manufacturer to offer gear hobbing heads in its standard range, and has continued to develop the holders for gearing technology ever since then. With this technology, it became possible for the first time to produce external gearing on machines without a Y/B-axis. In contrast to a standard milling wheel holder, the tool head of the EWS modular cutter can be swivelled about the axis of the shank. This offers users the advantage of substituting a B-axis with a comparatively small investment. In the meantime, module 3 has become commonplace on VDI40/BMT65/BMT75 machines. The tool heads have become more stable at the same time as being more user-friendly. The alignment system using a sinusoidal profile has come into widespread use and saves considerable alignment and setup times. Operating instructions, flyers and press reports can be found in our download portal Video: Gear hobbing on the

Request for a quote

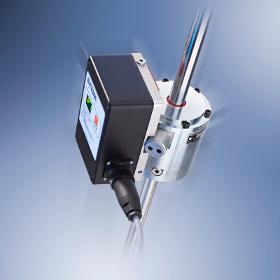

SITEMA GMBH & CO KG

Germany

KFE Special customer requirements Applications Overview Presses Machine Tools Automatization + Feeders Lifting Gear + Mobile Hydraulics Production Technology Special Machinery CAD Download Contact Electric Locking Unit The electric Locking Unit KFE is used as a stepless locking device on round rods and holds axial forces in both load directions without axial play. It is used where hydraulic or pneumatic solutions are not possible. The holding force is created by the proven spring-operated clamping system as it is used in SITEMA’s hydraulically or pneumatically operated Locking Units. At a drop of the control voltage or in case of failure of the electric supply, the Locking Unit KFE clamps automatically. Therefore, it is also suitable for use in safety relevant applications. To operate the Locking Unit KFE, a supply voltage of 24 V and a control signal for the input command “clamp/release” are sufficient. The Locking Unit is self-monitoring and provides output signals...

Request for a quote

SITEMA GMBH & CO KG

Germany

KRM Electric Locking Unit KFE Special customer requirements Applications Overview Presses Machine Tools Automatization + Feeders Lifting Gear + Mobile Hydraulics Production Technology Special Machinery CAD Download Contact Mechanical Safety Catcher The Mechanical Safety Catcher KRM is operated purely mechanically and requires neither a hydraulic nor a pneumatic system for control. The clamping head is kept open mechanically and acts upon rupture of the suspension (rope, belt, chain, etc.). The energy of the falling mass is then used to generate the clamping force. In applications where lifted loads can be dangerous in case of rupture of the suspension device, Safety Catchers KRM are used to protect people and assure accident prevention. Safety Catchers KRM secure the load at any point of the stroke in a mechanically safe and absolutely reliable way. Due to the principle of self-reinforcing clamping, a very high level of safety is reached. Application example Packing...

Request for a quote

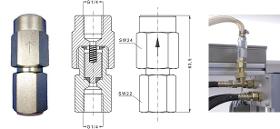

SITEMA GMBH & CO KG

Germany

Mechanical Safety Catcher KRM Electric Locking Unit KFE Special customer requirements Applications Overview Presses Machine Tools Automatization + Feeders Lifting Gear + Mobile Hydraulics Production Technology Special Machinery CAD Download Contact Auto Bleeder The SITEMA Auto Bleeder has been specially designed for the use with a SITEMA clamping head. It makes sure that the hydraulic system is constantly bled. Air bubbles in the hydraulic fluid might combust spontaneously under certain conditions (so-called Diesel effect). As a consequence, seals and sealing surfaces can be damaged, causing leakages. Clamping heads are especially susceptible for this phenomenon, as they have only a very small hydraulic volume and are not flushed through at each activation. Air can therefore easily accumulate in the clamping head. This is the reason why the usual initial bleeding at commissioning is often not enough, especially when the line leading to the clamping head points upwards...

Request for a quote

SITEMA GMBH & CO KG

Germany

Rod leaving clamping head Auto Bleeder Mechanical Safety Catcher KRM Electric Locking Unit KFE Special customer requirements Applications Overview Presses Machine Tools Automatization + Feeders Lifting Gear + Mobile Hydraulics Production Technology Special Machinery CAD Download Contact Mechanical Valve Actuator MVA Secure the rupture of a chain with the full comfort of a pneumatic SITEMA clamping head When a load has to be secured against rupture of a suspension device (e.g. a chain), many customers use our Mechanical Safety Catcher KRM. This unit has the advantage to hold the load immediately upon rupture of the suspension device. Additional sensors to detect rupture of a chain are not necessary. On the other hand, it is not possible to activate the KRM in a user-defined position without rupture of the suspension device, e.g. for maintenance purposes. Here, the Mechanical Valve Actuator MVA comes to your rescue. It is simply put between the suspension device and the...

Request for a quote

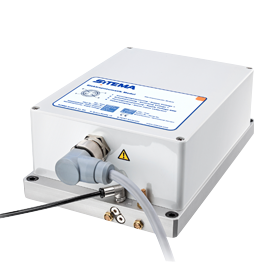

SITEMA GMBH & CO KG

Germany

Mechanical Valve Actuator MVA Rod leaving clamping head Auto Bleeder Mechanical Safety Catcher KRM Electric Locking Unit KFE Special customer requirements Applications Overview Presses Machine Tools Automatization + Feeders Lifting Gear + Mobile Hydraulics Production Technology Special Machinery CAD Download Contact Electropneumatic module EPM The Electropneumatic Module EPM acts as interface between (electrical) power supply / control and a pneumatic SITEMA clamping head. All pneumatic SITEMA clamping heads with an operating pressure of up to 4 bar and an operating volume of up to 220 cm³ can be pneumatically controlled by the EPM. It is also possible to operate several clamping heads in parallel with one EPM. The EPM is controlled by a 24V supply and switching voltage. The outlet pressure which is required to open or keep open a pneumatic clamping head is controlled by a control signal. If the voltage fails or the input signal is switched off, the pressure is...

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

As one of the largest independent contract manufacturers in Germany, the Pritzwalk gear factory (ZWP) based in Brandenburg undertakes the following production: Ring gears, gears, planetary gears, sun gears and shafts with internal gearing. Due to our generous outdoor storage area, ZWP can store the raw material for long-term procurement projects. This means that there are no lead times for special materials, so that a waiting time of e.g. 3-6 months can be avoided. Immediate access to materials is possible and production can take place immediately. The rising raw material prices, long waiting times or availability of the material used make warehousing and production according to defined lot sizes interesting again. Delivery call-offs can be made with immediate delivery capability and cost savings. Finished parts are of course preserved inside. We are looking for a conversation with you for a holistic solution.

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

As one of the largest independent contract manufacturers in Germany, the Pritzwalk gear factory based in Brandenburg undertakes the following production: Ring gears, gears, planetary gears, sun gears and shafts with internal gearing. Due to our generous outdoor storage area, ZWP can store the raw material for long-term procurement projects. This means that there are no lead times for special materials, so that a waiting time of e.g. 3-6 months can be avoided. Immediate access to materials is possible and production can take place immediately. The rising raw material prices, long waiting times or availability of the material used make warehousing and production according to defined lot sizes interesting again. Delivery call-offs can be made with immediate delivery capability and cost savings. Finished parts are of course preserved inside. We are looking for a conversation with you for a holistic solution.

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP is one of the leading independent manufacturer in Germany for gears, pinions and rim gears. We supply already well-known manufacturers for gear boxes. We are looking forward getting intouch with you to have a conversation about possibilities for your supply. Sectors of our (international) customers are: Mining, Oil, Offshore, rail and ship transmissions, industrial transmissions, and many more fields of applications. Overview about the capabilities for production: Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Internal toothed rings / rim gears hardened and grinded Module up to 20 mm - more on request Diameter 100 to 1,800mm Pinions and shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible Cooperation with companies for special manufacturing of gears and pinions etc We speak English.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of closed toothed gearing Liquid lubrication of chains, joints, guides, rolling and friction bearings Suitable for immersion-bath, immersion-bath circulation and injection lubrication Advantages and benefits NSF H1 registered Good ageing and oxidation stability through optimal additives Cold and hot water resistant Resistant to water steam, disinfectants and cleaning agents Wide operating temperature range Shear-stable and low-foaming Good wear protection Good corrosion protection Long economic operating times MOSH-/MOAH-free

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of closed toothed gearing Liquid lubrication of chains, joints, guides, fittings Suitable for immersion-bath, immersion-bath circulation and injection lubrication Advantages and benefits NSF H1 registered Good oxidation and ageing stability through optimal additives Cold and hot water resistant Resistant to water steam, disinfectants and cleaning agents Wide operating temperature range Shear-stable and low-foaming Good wear protection Good corrosion protection Long economic operating times MOSH-/MOAH-free

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of closed toothed gearing Liquid lubrication of chains, joints, guides, rolling and friction bearings Suitable for immersion-bath, immersion-bath circulation and injection lubrication Advantages and benefits NSF H1 registered Good ageing and oxidation stability through optimal additives Cold and hot water resistant Resistant to water steam, disinfectants and cleaning agents Wide operating temperature range Shear-stable and low-foaming Good wear protection Good corrosion protection Long economic operating times MOSH-/MOAH-free

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of closed toothed gearin Liquid lubrication of chains, joints, guides, rolling and friction bearings Suitable for immersion-bath, immersion-bath circulation and injection lubrication Advantages and benefits NSF H1-registered Good ageing and oxidation stability through optimal additives Cold and hot water resistant Resistant to water steam, disinfectants and cleaning agents Wide operating temperature range Shear-stable and low-foaming Good wear protection Good corrosion protection Long economic operating times MOSH-/MOAH-free

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP is one of Germany’s largest independent gear, pinion and shaft manufacturers. We manufacture according to customer drawings and supply renowned customers from a wide variety of industries. Here is an overview of our production possibilities: Gears and pinions internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Interlocking shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Internal toothed rings hardened and grinded Module up to 20 mm Diameter 100 to 1,800mm References to your industry on request We look forward hearing from you. Hardening and balancing inhouse possible Cooperation with companies for special manufacturing of gears and pinions etc We speak English.

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP is one of the leading independent manufacturer in Germany for gears, pinions and rim gears. We supply already well-known manufacturers for gear boxes, drive technology and are looking forward to new customers. Sectors of our (international) customers are: Mining, Oil, Offshore, rail and ship transmissions, industrial transmissions, and many more fields of applications. Overview about the capabilities for production: Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Internal toothed rings / rim gears hardened and grinded Module up to 20 mm - more on request Diameter 100 to 1,800mm Pinions and shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible Cooperation with companies for special manufacturing of gears and pinions etc We speak English. ZWP is looking forward hearing from you.

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP is one of the leading independent manufacturer in Germany for gears, pinions and ring gears. We supply already well-known manufacturers for gear boxes, drive technology and are looking forward to new customers. Sectors of our (international) customers are: Mining, Oil, Offshore, rail and ship transmissions, industrial transmissions, and many more fields of applications. Overview about the capabilities for production: Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Internal toothed rings / ring gears hardened and grinded Module up to 20 mm - more on request Diameter 100 to 1,800mm Pinions and shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible Cooperation with companies for special manufacturing of gears and pinions etc We speak English. ZWP is looking forward hearing from you.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NIDEC GRAESSNER GMBH & CO. KG THE GEAR COMPANY

Germany

Almost no-one understands complex construction as well as MS-Graessner, due to the fact that the gear tooth and gear specialist‘s creations are based on more than 60 years of experience. Intelligent solutions for a wide range of sectors and applications make MS-Graessner a reliable industry partner in both gear tooth technology and gear construction.

Request for a quote

NIDEC GRAESSNER GMBH & CO. KG THE GEAR COMPANY

Germany

Takeover of the Torus gear technology In September 2016, MS-GRAESSNER GmbH & Co. KG acquired the entire technical expertise of TEDEC AG, Zofingen/Switzerland. Read more ... This results in an ideal synergy effect: state-of-the-art gear meshing technology combined with many years of experience in gear engineering. The further development of the TORUS gearbox (TorusGear), including series development, is thus guaranteed - also from the perspective of customer-specific applications. The owner-managed company MS-GRAESSNER GmbH & Co. KG is a manufacturer of high-precision servo angular gearboxes, with over 60 years of experience in drive technology. The products are used in particular in the fields of automation, robotics, electromotive, and mechanical and plant engineering.

Request for a quote

ECKARDT SYSTEMS GMBH

Germany

32 Series Our compact felt roller lubricators are designed for coil gauges up to 0.5 mm as well as viscosities up to 100 mm 2/sec (recommended guideline values). Fields of application Contact components: tab connectors, electric switching contacts, contact springs Punched and bent parts: medical technology, microelectronics, precision engineering Fine blanked parts: gear/engine technology, pumps

Request for a quote

NIDEC GRAESSNER GMBH & CO. KG THE GEAR COMPANY

Germany

Forget everything you know about miniature gears. Dimensions, weight, precision – the new Power Gear Miniature sets new standards. PowerGear Miniature has a sensationally small installation size, an extremely light-weight aluminium housing, maximum performance and precision as well as many other advantages. The unique design of PowerGear Miniature will open up a vast range of applications in drive technology. miniature gear for maximum precision low backlash and high transmission accuracy case-hardened bevel gear tooth system friction-locked shaft-and-bevel-gear fit energy-efficient through high level of efficiency of 98% extremely light-weight aluminium housing maintenance free through synthetic oil

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP is one of the leading independent manufacturer in Germany for gears, pinions and rim gears. We supply already well-known manufacturers for gear boxes, drive technology and are looking forward to new customers. Sectors of our (international) customers are: Mining, Oil, Offshore, rail and ship transmissions, industrial transmissions, and many more fields of applications. Overview about the capabilities for production: Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Internal toothed rings / rim gears hardened and grinded Module up to 20 mm - more on request Diameter 100 to 1,800mm Pinions and shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible Cooperation with companies for special manufacturing of gears and pinions etc We speak English. ZWP is looking forward hearing from you.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

High-performance gear oil in Aral synthesis technology with smooth-running properties. Multi-range character SAE 75W-90 for passenger car manual transmissions, two-wheel transmissions and transaxles as well as for commercial vehicle units (e.g. trucks, construction machinery, agricultural units) Specifications API GL-4+ VW 501 50

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The L-10 series has our smallest and most compact hydraulic drive with helical gearing. With its extremely high axial load capacity in a slim, cylindrical design with flange mounting and drive, the ultra-compact L-10 series is ideal for applications with limited space. Helac’s sliding spline hydraulic technology with helical gearing is not self-locking and offers both high impact resistance and high holding torque for demanding applications. The L-10 series functions as a rotating device as well as a mounting bracket and support structure, so that no external bearing systems, brakes or locking devices are required. Available in five standard sizes with an output torque of up to 2,825 Nm at 210 bar.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The L-10 series has our smallest and most compact hydraulic drive with helical gearing. With its extremely high axial load capacity in a slim, cylindrical design with flange mounting and drive, the ultra-compact L-10 series is ideal for applications with limited space. Helac’s sliding spline hydraulic technology with helical gearing is not self-locking and offers both high impact resistance and high holding torque for demanding applications. The L-10 series functions as a rotating device as well as a mounting bracket and support structure, so that no external bearing systems, brakes or locking devices are required. Available in five standard sizes with an output torque of up to 2,825 Nm at 210 bar.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The L-10 series has our smallest and most compact hydraulic drive with helical gearing. With its extremely high axial load capacity in a slim, cylindrical design with flange mounting and drive, the ultra-compact L-10 series is ideal for applications with limited space. Helac’s sliding spline hydraulic technology with helical gearing is not self-locking and offers both high impact resistance and high holding torque for demanding applications. The L-10 series functions as a rotating device as well as a mounting bracket and support structure, so that no external bearing systems, brakes or locking devices are required. Available in five standard sizes with an output torque of up to 2,825 Nm at 210 bar.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The L-10 series has our smallest and most compact hydraulic drive with helical gearing. With its extremely high axial load capacity in a slim, cylindrical design with flange mounting and drive, the ultra-compact L-10 series is ideal for applications with limited space. Helac’s sliding spline hydraulic technology with helical gearing is not self-locking and offers both high impact resistance and high holding torque for demanding applications. The L-10 series functions as a rotating device as well as a mounting bracket and support structure, so that no external bearing systems, brakes or locking devices are required. Available in five standard sizes with an output torque of up to 2,825 Nm at 210 bar.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The L-10 series has our smallest and most compact hydraulic drive with helical gearing. With its extremely high axial load capacity in a slim, cylindrical design with flange mounting and drive, the ultra-compact L-10 series is ideal for applications with limited space. Helac’s sliding spline hydraulic technology with helical gearing is not self-locking and offers both high impact resistance and high holding torque for demanding applications. The L-10 series functions as a rotating device as well as a mounting bracket and support structure, so that no external bearing systems, brakes or locking devices are required. Available in five standard sizes with an output torque of up to 2,825 Nm at 210 bar.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The L-10 series has our smallest and most compact hydraulic drive with helical gearing. With its extremely high axial load capacity in a slim, cylindrical design with flange mounting and drive, the ultra-compact L-10 series is ideal for applications with limited space. Helac’s sliding spline hydraulic technology with helical gearing is not self-locking and offers both high impact resistance and high holding torque for demanding applications. The L-10 series functions as a rotating device as well as a mounting bracket and support structure, so that no external bearing systems, brakes or locking devices are required. Available in five standard sizes with an output torque of up to 2,825 Nm at 210 bar.

Request for a quoteResults for

Gear technology - Import exportNumber of results

38 ProductsCountries

Company type

Category

- Electric motors and parts (11)

- Gears (6)

- Silicones (4)

- Mechanical transmission - components (2)

- Mining and quarrying - machinery and equipment (2)

- Pinions (2)

- Boring - steels and metals (1)

- Electronic components (1)

- Extraction machinery and equipment - minerals and ores (1)

- Handling - Machines & Equipment (1)

- Lifts and platform elevators, car (1)

- Locomotives - equipment (1)

- Lubricants, industrial (1)

- Milling - machine tools (1)

- Mining, surface - machinery and equipment (1)