- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- gear rack

Results for

Gear rack - Import export

NORELEM FRANCE

France

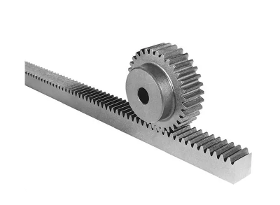

Milled toothing, straight teeth engagement angle 20°, bright. Outside diameter extruded, tolerance h9. Note The gear rack teeth are cut using a hob mill. This results in minus tolerances for dimensions H and H1 up to module 2 0.2 mm. module 2.5 to 3 0.3 mm.

Request for a quote

NORELEM FRANCE

France

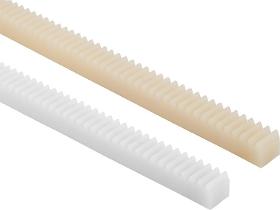

Injection moulded, straight teeth. Engagement angle 20°. Polyacetal, white. Polyketone, ivory tone. Note Polyacetal Standard material with high hardness grade and low coefficient of friction. Polyketone Material with significantly longer service life, higher power transmission and greater security against tooth breakage due to the extraordinarily high wear resistance and very good tribological properties. Can be used under water and other media. Due to the material properties, plastic gear racks are not straightened. L= nominal length 250 mm. The actual length is roughly a whole multiple of the pitch.

Request for a quote

NORELEM FRANCE

France

Milled toothing, straight teeth. Engagement angle 20°, bright. Note The gear racks are suitable for mounting in series.

Request for a quote

HAACON HEBETECHNIK GMBH

Germany

haacon hebetechnik gmbh expands its standard range to include rack and pinion winches with fastening lugs for wall mounting. The serial drive type is a spring-loaded safety crank (SiFeKu), which holds the load in any desired position under tensile and compressive loading. The winch can be utilised in any position. The winches are produced in three load classes: 1.5 t 3 t 5 t. The robust design with milled gear rack and hardened gear components is suitable for use in harsh applications. The crank handle can be moved for space efficiency. Special designs with other rack and pinion lengths, detachable crank design, assembled fastening options can be supplied at short notice.

Request for a quote

ERKAS MACHINE AND GEAR INDUSTRY

Turkey

ERKAS Machine and gear supplier of rack gears in turkey since 1969

Request for a quote

TURGAY GEAR MACHINE

Turkey

Our gear rack manufacturing capacity is from 0.5 to 15 modules with a maximum he

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Our company has 25 years experience for manufacture different kinds of gears.And our company has many advanced production equipments. such as CNC forming grinding wheel grinding machines, gantry machining centers, four axis and five axis machining centers, CNC lathes, CNC gear shapers, CNC milling machines, CNC hobbing machines, gear chamfering machines.and more than 40 sets of processing and testing equipment. we can provide various professional production services such as precision gear wheel machining, CNC machining, CNC turning machining, and so on.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Our company has 25 years experience for manufacture different kinds of gears.And our company has many advanced production equipments. such as CNC forming grinding wheel grinding machines, gantry machining centers, four axis and five axis machining centers, CNC lathes, CNC gear shapers, CNC milling machines, CNC hobbing machines, gear chamfering machines.and more than 40 sets of processing and testing equipment. we can provide various professional production services such as precision gear wheel machining, CNC machining, CNC turning machining, and so on.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Our company has 25 years experience for manufacture different kinds of gears.And our company has many advanced production equipments. such as CNC forming grinding wheel grinding machines, gantry machining centers, four axis and five axis machining centers, CNC lathes, CNC gear shapers, CNC milling machines, CNC hobbing machines, gear chamfering machines.and more than 40 sets of processing and testing equipment. we can provide various professional production services such as precision gear wheel machining, CNC machining, CNC turning machining, and so on.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Our company has 25 years experience for manufacture different kinds of gears.And our company has many advanced production equipments. such as CNC forming grinding wheel grinding machines, gantry machining centers, four axis and five axis machining centers, CNC lathes, CNC gear shapers, CNC milling machines, CNC hobbing machines, gear chamfering machines.and more than 40 sets of processing and testing equipment. we can provide various professional production services such as precision gear wheel machining, CNC machining, CNC turning machining, and so on.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Our company has 25 years experience for manufacture different kinds of gears.And our company has many advanced production equipments. such as CNC forming grinding wheel grinding machines, gantry machining centers, four axis and five axis machining centers, CNC lathes, CNC gear shapers, CNC milling machines, CNC hobbing machines, gear chamfering machines.and more than 40 sets of processing and testing equipment. we can provide various professional production services such as precision gear wheel machining, CNC machining, CNC turning machining, and so on.

Request for a quote

NORELEM FRANCE

France

Injection moulded, straight teeth. Engagement angle 20°. Axis angle = 90°. Machined bores from module 1.5. Polyacetal, white. Polyketone, ivory tone. Note Polyacetal Standard material with high hardness grade and low coefficient of friction. Polyketone Material with significantly longer service life, higher power transmission and greater security against tooth breakage due to the extraordinarily high wear resistance and very good tribological properties. Can be used under water and other media. Injection moulded gear wheels may have internal manufacturerelated cavities. These may become visible during drilling or broaching. They do not impair the function. Bevel gear wheels are supplied as single components. To obtain a pair of bevel gear wheels, please order the specified mating gear as well.

Request for a quote

NORELEM FRANCE

France

Milled toothing, straight teeth. Engagement angle 20°, bright. Axis angle = 90°. Note for ordering Bevel gears are supplied singly. To obtain a pair of bevel gears, please order the specified mating gear as well.

Request for a quote

NORELEM FRANCE

France

Milled toothing, straight teeth. Engagement angle 20°, bright. Note Up to 70 teeth with hub one side, from 80 teeth supplied as disc form. The spur gears have a centre bore or pilot hole (this can vary due to manufacturing methods). For this reason, the dimension D2 max. given in the table is the maximum diameter of the bore with which the spur gears are supplied. This pilot/centre bore can be amended by the customer to produce a reamed bore, reamed bore with keyway or a tapped hole. Alternatively, customers can also use bushes to reduce the bore diameter. Drawing reference Form A with hub Form B without hub

Request for a quote

NORELEM FRANCE

France

Milled toothing, straight teeth. Engagement angle 20°, bright. Note Up to 48 teeth with hub one side, from 50 teeth supplied as disc form. The spur gears have a centre bore or pilot hole (this can vary due to manufacturing methods). For this reason, the dimension D2 max. given in the table is the maximum diameter of the bore with which the spur gears are supplied. This pilot/centre bore can be amended by the customer to produce a reamed bore, reamed bore with keyway or a tapped hole. Alternatively, customers can also use bushes to reduce the bore diameter. Form A with hub Form B without hub

Request for a quote

NORELEM FRANCE

France

Injection moulded, straight teeth. Engagement angle 20°. Machined bore. Polyacetal, white. Polyketone, ivorytone. Note Polyacetal Standard material with high hardness grade and low coefficient of friction. Polyketone Material with significantly longer service life, higher power transmission and greater security against tooth breakage due to the extraordinarily high wear resistance and very good tribological properties. Can be used under water and other media. Injection moulded gear wheels may have internal manufacturerelated cavities. These may become visible during drilling or broaching. They do not impair the function. The torques specified in the tables relate exclusively to the toothing.

Request for a quote

GSW SCHWABE AG

Germany

With threephase servo drive sized according to job requirements Machine body in sturdy clean steel plate design Rollers made of highquality 63 RW tool steel, hardened and polished Pneumatic pilot release with parallel lift of upper roller, guided on gear rack Entry catenary rolls Manual edge guides Simple programming of even complex feeding cycles, Display in cleartext Manual functions for setup such as creep speed, jog mode, single feedtolength Simple memory and recall of job programs for quick changeover Mounting bracket with height adjustment via spindle or hydraulic handpump (optional motorized) Hard chromed or polyurethane coated rollers (optional with Topochrome coating for highgrip feeding) Measuring wheel system for highest feeding accuracy Stroke limitation for faster piloting Fine adjustment of upper roller and strip guiding device for thin stocks (starting at 0,1 mm thickness) Central edgeguides with hand wheel

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

![GearSystems [2.0]](/filestore/vig280/opt/product/84/ee/dynaGear-Eco_0992140d.jpg)

NIDEC GRAESSNER GMBH & CO. KG THE GEAR COMPANY

Germany

System Solutions for Rack and Pinion Applications As a supplement to the well-known gearbox product ranges, MS-Graessner offers system solutions in the field of rack and pinion applications for mechanical and plant engineering. The DynaGear, KS-TwinGear, DynaGear DG and DynaGear PL systems consist of precise system components developed for automation technology. These include: low-backlash precision gearboxes spur gears toothed racks lubrication systems With planetary gear output flange 3 sizes from T2B= 53 Nm to 210 Nm Feed forces up to 8 kN 2 precision classes Input speeds up to n1max = 5000 min-1 Feed speeds up to 6 m/s Gear ratios from 5:1 to 15:1 Spur gear modules from m2 bis m4

Request for a quote![GearSystems [2.0]](/filestore/vig280/opt/product/6d/7d/ks30kh_815e350b.jpg)

NIDEC GRAESSNER GMBH & CO. KG THE GEAR COMPANY

Germany

System Solutions for Rack and Pinion Applications As a supplement to the well-known gearbox product ranges, MS-Graessner offers system solutions in the field of rack and pinion applications for mechanical and plant engineering. The DynaGear, KS-TwinGear, DynaGear DG and DynaGear PL systems consist of precise system components developed for automation technology. These include: low-backlash precision gearboxes spur gears toothed racks lubrication systems 8 sizes from T2B = 225 Nm to 11250 Nm Feed forces up to approximately 200 kN 3 precision classes Input speeds up to n1max = 8000 min-1 Feed speeds up to 4 m/s Gear transmission ratios from 15:1 to 75:1 Spur gear modules from m2 to m8

Request for a quote![GearSystems [2.0]](/filestore/vig280/opt/product/af/c8/dynaGear-Ritzel_67543e7d.jpg)

NIDEC GRAESSNER GMBH & CO. KG THE GEAR COMPANY

Germany

System Solutions for Rack and Pinion Applications As a supplement to the well-known gearbox product ranges, MS-Graessner offers system solutions in the field of rack and pinion applications for mechanical and plant engineering. The DynaGear, KS-TwinGear, DynaGear DG and DynaGear PL systems consist of precise system components developed for automation technology. These include: low-backlash precision gearboxes spur gears toothed racks lubrication systems 8 sizes from T2B= 53 Nm to 2160 Nm Feed forces up to approximately 35 kN 3 precision classes Input speeds up to n1max = 8000 min-1 Feed speeds up to 10 m/s Gear ratios from 3:1 to 100:1 Spur gear modules from m2 to m6

Request for a quote

TOSYALI MAKINA A.S.

Turkey

The rack can be thought of as a gear part with infinite radius, or more simply, it is a straight rod with gear teeth. Rack and pinion gear systems do not offer as much mechanical power as other systems, but they close this gap by providing more feedback. For example, using a rack and pinion system on a car's steering column will provide better steering feel. As a mechanical element that transfers rotation to linear motion, gear racks are often compared to ball screws. There are pros and cons to using racks instead of ball screws. The advantages of the gear rack are its mechanical simplicity, large load carrying capacity and no length limitation.

Request for a quote

ILK IHRACAT AS.

Turkey

Gear manufacturing consists of the following basic steps: Material selection: Various materials, such as steel, aluminum, plastic, or others, can be used in gear manufacturing. Material selection is made according to the purpose of the gear. Gear profile design: The gear profile is designed Gear mold production: The gear mold is produced according to the gear profile. Gear production: The gear is produced using the selected method. Gear inspection: The gear is inspected after production. Get a Quote Now Contact us immediately for the most suitable production solutions for your gear needs. Our professional team is ready to provide you with exclusive offers. Who Are We: Steeling.Net carries out partner marketing activities in the Turkish metal industry. Our partner manufacturers are companies that specialize in sheet and steel processing and have a wide product range.

Request for a quote

WALTER UHL TECHNISCHE MIKROSKOPIE GMBH & CO. KG

Germany

Quick adjustment by knurled knob and two dovetail bearings with gear rack.

Request for a quote

UNIL LUBRICANTS

Belgium

Supergrease 350 is an “extreme pressure” (EP) grease with a very high performance level for all uses (joints, gear racks, axles, bearings, cables, open gears, ...) This grease also possesses excellent adhesive properties. Supergrease 350 was purpose-designed for the lubrication of various mechanisms under the most demanding operational circumstances. Benefits Broad temperature range. Exceptional adhesion to metal surfaces. Remarkable resistance to corrosion. Outstanding water-resistance.

Request for a quote

HAACON HEBETECHNIK GMBH

Germany

Rack & pinion jack 1524 Inox Rack & pinion jack, load 0,5 t, easy functioning, self-locking worm gear, stainless steel Rack & pinion jack for lifting, lowering, adjusting and fixing of mechanical components, devices, machines etc

Request for a quote

HAACON HEBETECHNIK GMBH

Germany

Rack & pinion jack 1524Rack & pinion jack, load 0,5 t, easy functioning, self-locking worm gear, also available stainless steel Rack & pinion jack 1555 Rack & pinion jack, load 1 t, easy functioning, self-locking worm gear Rack & pinion jack 1557 Rack & pinion jack for lifting, load 1 t, easy functioning, self-locking worm gear, rack inhoused

Request for a quote

ERKAS MACHINE AND GEAR INDUSTRY

Turkey

ERKAS Machine and gear industry manufacturer of spur gear, helical gear, bevel gear, rack gear since 1989 in Turkey

Request for a quote

ERKAS MACHINE AND GEAR INDUSTRY

Turkey

ERKAS Machine supplier of spur gear, helical gear, bevel gear, rack gear in Turkey since 1989

Request for a quote

OGGO TECH GEARS, ROLLERS, ENGINEERING

Turkey

Over 3400mm dia, this Gear is manufactured by us, OGGO Tech excels at producing gears in Turkey, others include spur gears, helical gears, worm gears, herringbone gears, pto gears, pinion and racks, pinion gears, sprocket gears, bevel gears, ground gears, transmission components. Turkey gear manufacturing and We carry out our gear manufacture without any issues as a professional CNC milling and manufacturing firm. Through our high-quality business, we are the first to choose our gear sets. The selected applications in tool and gear production are determined by the part, manufacturing time periods, and eventually their dimensions. Gear manufacturing is generally done in soft step procedures, where exact dimensional tolerances are likely to be difficult to achieve. To establish a problem-free hardening lathe, careful preparation for a hardened stage in gear production is essential. Hard operations in gears are easier to undertake at this level.

Request for a quoteResults for

Gear rack - Import exportNumber of results

32 ProductsCountries

Company type

Category

- Gears (14)

- Casting, steel (3)

- Hoists and winches (2)

- Metal cutlery (2)

- Agriculture - Machines & Equipment (1)

- Machine tools, cutting - parts and accessories (1)

- Machine tools, metal machining - parts and accessories (1)

- Measurement - Equipment & Instruments (1)

- Metal straightening machines (1)

- Metallurgy - machinery and installations (1)

- Metallurgy and iron and steel industry - machinery and installations (1)