- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- gas welding - equipment and supplies

Results for

Gas welding - equipment and supplies - Import export

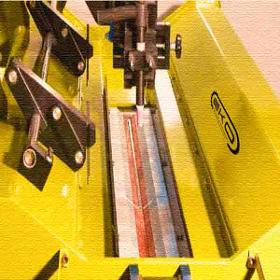

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The gap between the looped wires defines the filtration performance of the welded wedge wire screen. Welded wedge wires are used as a filter to eliminate bigger sizes or types of materials above the wedge wire screen. Special manufacturing is required to create equal loops between the welded wires. Welded wedge wire screen is used in heavy applications for high filtration performance. The main advantages of welded filter screen are Advantages Special surface treatment Modular and customizable design High durability Suitable for heavy applications Superior filtering with unique screen Long service life & less maintenance Looped wedge wire screen is adaptable for many applications including Applications Coal and Gold Mining Filtration Mineral Processing Water Treatment Petrochemical Applications Food Processing Stainless steel with different grades and different materials can be used. Also, special surface treatments are available for your application.

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

Option for black glass No. 9, 10 or 11

Request for a quote

TUSKER INDUSTRIAL SAFETY

United Kingdom

If you’re looking for a welding bay system, welding booth, or a bay system for any other purpose, no matter how extensive, Tusker Industrial Safety can deliver. Our technical team will consult with you and design a welding booth to meet your exact requirements. With a wide range of curtain materials (including PVC strip curtains) and fixing systems available, our versatile, modular solutions will suit your application. We can provide all the necessary supplementary documentation including technical drawings, risk assessments and method statements. A dedicated project manager will keep you informed at every stage of the process.

Request for a quote

PROTEC TRADING GMBH

Austria

English | Deutsch | Español | Português | Français | Italiano | Русский Visit our website for information in your language. Welding-Milk PROTEC CE16M Light biological separation agent to prevent adhesion of weld spatter on components. Particularly suitable for thin sheet metal panels, optimised to produce minimum emissions and leave minimum residue. Protects any type of metal surfaces, except aluminium. No silicone, non-flammable, and biodegradable.

Request for a quote

EKO WELDING & MACHINE AUTOMATION SYSTEMS

Turkey

Rotators are resistant to severe working conditions and are designed to rotate work pieces weighing 5 to 150 tons. It enables the cylindrical parts weld sensitively by rotating clockwise or anticlockwise. In line with customer’s demanded diameter and tonnages, its production can be made auto regulative or conventionally. Features -Through polyurethane coated wheels rotation quakes and uploading hitting are absorbed during welding. -In the applications requiring high temperature and major load, featured steel wheels can be used as well. -Wheels possess self-adjusting feature for small or big diameters. This adjustment can be made with ball screw or by hand optionally. -For the manual usage, digital control or analog entries can be integrated to Column Bom systems. -Sensitive rotation with low gaped reducer -Synchronised working feature -Power transmission with flat gears

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

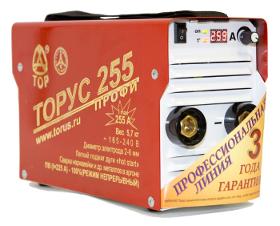

COMPANY TOR

Russia

TORUS-255 has the widest possible range of arc welding currents (from 20 to 255 A), which makes it possible to use it both for welding very thin metals, including in the TIG mode (welding with non-consumable electrode), and for continuous welding of large metal structures using an electrode up to 6 mm in diameter. The operating margin in the ТОРУС-255 device is such that it can be effectively used not only for the MMA and TIG modes, but also in the surfacing and cutting modes. At the same time, the weight of the device itself is traditionally not big – only 5.7 kg. Like all devices of the ТОРУС line, ТОРУС-255 has increased reliability with all its maximum parameters. A 3-year manufacturer’s warranty is a guarantee of its high performance in the most severe operating conditions.

Request for a quote

COMPANY TOR

Russia

The inverter machine VIKING 500A PRO is used for manual arc welding of metal blanks. The inverter has a functional control panel with a digital display that displays the main operating parameters. The device is equipped with overload protection and voltage surge protection. The technologies applied during the manufacture of VIKING 500A PRO devices allow performing any tasks in welding, surfacing and cutting metal structures for performing work with any kind of electrodes with a diameter of up to 6 mm and a maximum arc welding current of up to 500А (100% at 420 A). The welding inverter machine can be used at low temperatures and reduced supply voltage. Adjustable functions of hot start and arc reheat imply the ability to adjust the operation of the device with minimal spattering and allow you to perform work in any spatial position of the electrode and welded surfaces.

Request for a quote

COMPANY TOR

Russia

Welding inverters of the PRO series are light in weight and dimensions. The metal housing reliably protects the internal components, making it suitable for use on the construction site. Inverters are capable to operate with all brands of stick electrodes from 1.6 to 5 mm and 6 mm (VIKING 250PRO, VIKING 270PRO), including the УОНИ 13/55 brand. The minimum arc welding current is 30 A, the maximum one corresponds to the model. TP at maximum current for all models is 60%. Mains voltage range is 160 ... 260 V.

Request for a quote

SEIT ELETTRONICA SRL

Italy

IMPROVE YOUR HEATING PROCESS PLATINUM MF Series is the new range of Medium-Low Frequency Induction Generators, ideal for all heating automatic or manual processes. With the MF generators, you have a total control of the heating process and you get high quality results. MF generators guarantee you repetitiveness and precision in reduced time. CHARACTERISTIC Model: Platinum MF5 - 10 - 15 - 25 Output power (kW): 5kW - 10kW - 15kW - 25kW Duty Cycle: 100% Frequency range: 15 kHz -55 kHz Output power regulation: 10 - 100% Power supply: 400V - 3ph - 50/60Hz Cooling: H2O demineralized FEATURES - Touch-screen display 7” - Digital control of all functions - Creation and saving of multistep programs - Heating profiles based on temperature and / or power - USB connection - Multilingual user interface

Request for a quote

SEIT ELETTRONICA SRL

Italy

IMPROVE YOUR HEATING PROCESS PLATINUM HF Series is the new series of high frequency induction generators, suitable for manual and /or automatic heating of medium-small parts. Ideal for fast and controlled heating processes, such as annealing and hardening. Thanks to their versatile characteristics and smart design, the PLATINUM generators are recommended for manual use as well as integration in automatic processes. CHARACTERISTIC Model: Platinum HF Output power (kW): 2.5kW /3kW / 6kW Duty Cycle: 50% / 100 % Frequency range: 200 kHz -600 kHz Output power regulation: 10 - 100% Power supply: 230V - 1ph - 50/60Hz Cooling: H2O demineralized FEATURES - Touch-screen display 7” - Digital control of all functions - Creation and saving of multistep programs - Heating profiles based on temperature and / or power - USB connection - Multilingual user interface

Request for a quote

EKO WELDING & MACHINE AUTOMATION SYSTEMS

Turkey

It’s designed upon you weld cylindrical, conical and rectangle shaped bended frameworks and in shape of flat slab metal sheet and plaque linearly. Frameworks that are between 200-3000 mm diameters can be welded on different types of machines easily. Its production can be made from the length of 0.5 meter to 4 meters. Upon customer demand the length can be increased. As to application method, TIG, MIG and submerged welds can be adapted. Materials’ like boiler, thermosiphon, solar power boilers, cooling tanks, natural gas funnels, lpg tubes etc., height welds are made on this machine.

Request for a quoteResults for

Gas welding - equipment and supplies - Import exportNumber of results

12 ProductsCompany type

Category

- Welding, soldering and brazing - equipment and supplies (6)

- Welding, electric - equipment and supplies (5)

- Autogenous welding machines (3)

- Brazing - equipment and supplies (2)

- Electron beam welding - equipment (2)

- Welding work - steels and metal (2)

- Filtering equipment and supplies (1)

- Laser - cutting and welding machines (1)