- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- gas heat exchangers

Results for

Gas heat exchangers - Import export

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

A flue gas heat exchanger is part of the standard equipment for energy-optimised and environmentally friendly boiler operation. — Effective heat recovery and reduction of flue gas losses — Maximum efficiency gain when using condensing technology — Fuel savings of up to 7%, or up to 15% when using condensing technology — Intelligent control for a long service life and high level of efficiency — Compactly integrated into the boiler or as a stand-alone version for simple retrofitting

Request for a quote

NC MANUFACTURING AND ENGINEERING

Turkey

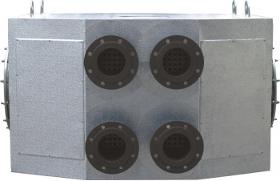

Engines for combined heat and power plants are operated with different fuels, including hydrogen, natural gas, biogas, sewage gas and special gases, plus diesel and other liquid fuels. In an exhaust gas heat exchanger, the hot exhaust gas from the CHP engines or CHP gas turbines is cooled, in the process heating water, a water-glycol mixture or thermal oil. This thermal energy can be used in a local or district heating system or for other industrial purposes.

Request for a quote

NC MANUFACTURING AND ENGINEERING

Turkey

Exhaust gas bypass systems are made as additional equipment in exhaust gas heat exchangers. 3-way flap is required for bypass systems. By-passing the gas flow makes it possible to adjust temperature inside boiler (exhaust gas heat exchanger). Before delivery, we do a thorough test drive for every single damper, using actuator and special measurement equipment, to make sure that they function as expected and are ready to serve reliably on site. Availaible in steel, stainless steel or heat resistant materials Flange type and size depending on customer needs We develop dampers in different sizes and various temperature ranges Actuator options; Pneumatic actuator, Electrical actuator

Request for a quote

NC MANUFACTURING AND ENGINEERING

Turkey

Heat transfer between a gaseous media and a liquid finned tube heat exchangers are often called air/water heat exchangers or gas/water heat exchangers. Heat transfer between a gas (for ex. air, steam) and a liquid (for ex. water, seawater, oil) takes place in the air-/water heat exchangers. Very often air/water heat exchangers are used as exhaust heat exchanger to gain the energy out of warm or hot exhaust fumes. Finned tube radiators can also be used as air heater, air cooler or condenser To improve the thermal output transfer from the gas to the liquid, fins made of well heat transferring materials are put on the tubes. The great increase of the thermal efficiency when applying fin tubes allows a substantial reduction in size and costs of such cooling equipment. The surface of such tubes is substantially increased and consequently less tubes are required compared with exchangers with plain tubes.

Request for a quote

APROVIS

Germany

What you can expect from an APROVIS process gas heat exchanger: - Suitable for low and high temperature ranges - Operating pressures up to 160 bar - Compact design for use in confined spaces - Suitable for a wide range of gases - Implementation of customised solutions

Request for a quote

APROVIS

Germany

What you can expect from APROVIS exhaust gas heat exchangers: - Efficient hot water generation in combined heat and power plants - Heating of thermal oil as an energy source - Individual solutions and compact designs - All the main components for the exhaust gas section and gas treatment are combined under one roof: proprietary products developed in-house - Cost-saving and reliable operation of the systems - Maximum functionality, safety and service - Temperature ranges: up to 600°C on the exhaust gas side or up to more than 1,000°C in the high-temperature range - Maximum functionality, safety and service - Temperature ranges: up to 600°C on the exhaust gas side or up to more than 1,000°C in the high-temperature range - Certifications: PED 2014/68/EU, ASME Code, EAC - Can be used in all plants with exhaust gases from hydrogen, natural gas, biogas, sewage gas and special gases, plus diesel and other liquid fuels - Geared to international standards and directives

Request for a quote

ANTHERMO GMBH

Germany

Air-water / air-air heat exchanger as smooth tube heat exchanger up to 1,000 ° C Smooth tube heat exchanger as an air / water heat exchanger In the case of air-water heat exchangers (also called gas-water heat exchangers), a temperature exchange takes place between a gas (usually air) and a liquid. As a rule, the liquid medium flows inside the pipes, while the gaseous medium flows around the pipes outside the pipes. Smooth tube heat exchangers can cover various areas of application: heating, cooling and condensing as well as heat recovery. Smooth tube heat exchanger as air-to-air heat exchanger Smooth tube heat exchangers are also often used as air-to-air heat exchangers. In this application, a gas (e.g. exhaust air or exhaust gases) flows inside the pipes and a gas (e.g. fresh air) outside the pipes around the pipes.

Request for a quote

ANTHERMO GMBH

Germany

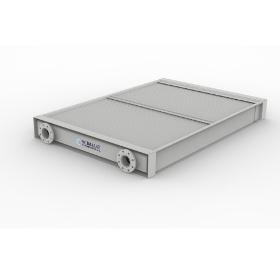

Temperature control of gaseous and liquid media Flat tube heat exchangers are generally used as air / air or air / liquid heat exchangers. Flat tube heat exchangers are used where the (exhaust) air is polluted and the installation space is limited. In heat recovery in particular, there are numerous applications for flat tube heat exchangers as so-called exhaust gas / exhaust air heat exchangers. Little installation space and less pressure loss While the rows of tubes in smooth tube heat exchangers consist of round tubes, the rows of tubes in flat tube heat exchangers have a special profile (see illustration). This special tube profile offers advantages over the round profile in certain applications. Flat tube heat exchangers require less installation space than smooth tube heat exchangers with the same exchange area and are therefore also lighter.

Request for a quote

ANTHERMO GMBH

Germany

Temperature exchange between a gas and a liquid In the case of air-water heat exchangers (also called gas-water heat exchangers), there is a temperature exchange between a gas (usually air) and a liquid. Finned heat exchangers can cover various areas of application: - heating and evaporating, - cooling and condensing as well as heat recovery. In this context, lamellar heat exchangers are also called air heaters or air coolers. Air-water heat exchangers are often also used as exhaust gas heat exchangers or flue gas heat exchangers in order to recover the energy from warm or hot exhaust gases. Lamella packs for a large exchange area In order to achieve the largest possible exchange surface between the air and the medium (liquid) within the heat exchanger, lamellas or lamella packs are attached to the pipe system.

Request for a quote

ANTHERMO GMBH

Germany

Air heat exchangers as finned tube heat exchangers Heat transfer between a gaseous media and a liquid Finned tube heat exchangers are often called air/water heat exchangers or gas/water heat exchangers. Heat transfer between a gas (for ex. air) and a liquid (for ex. water) takes place in the air-/water heat exchangers. To improve the thermal output transfer from the gas to the liquid, fins made of well heat transferring materials are put on the tubes. Very often air-/water heat exchangers are used as exhaust heat exchanger to gain the energy out of warm or hot exhaust fumes. Finned tube heat exchangers can also be used as air heater, air cooler or condenser.

Request for a quote

APROVIS

Germany

* Exhaust gas heat exchangers * Steam generators * Silencers * Oxidation and three-way catalytic converters * SCR catalytic converters/Diesel SCR catalytic converters * Diesel particulate filters * Chimneys

Request for a quote

APROVIS

Germany

* FriCon - gas dehumidification * Gas heaters * ActiCo - activated carbon filters * Gas compressors * Process gas heat exchangers

Request for a quote

APROVIS

Germany

What you can expect with an APROVIS FriCon: - FriCon systems are ready for connection - The FriCon removes the moisture from the process gas by dropping below the dew point temperature - FriCon gas heat exchangers operate at elevated pressure, ambient pressure and negative pressure - Condensate formation in downstream gas lines is avoided - Suspended matter is separated - The FriCon is available in different sizes and designs

Request for a quote

THERMOTEC PRODUKTIONSGESELLSCHAFT MBH

Germany

THERMO-GAS Heat Exchangers work optimally if the constant flow of gasses into the heat exchanger is guaranteed. In case of unfavourable assembly conditions, we have made tests and measurements so far in order to optimise stream conditions. Due to the increased requirements on the performance of heat exchangers as well as expanded application areas it has become necessary to achieve optimised results already in the planning phase. This is done by means of a CAD-based simulation which enables the very exact predicition of stream conditions. The performance opportunities of our heat exchangers are used at the best as a result of appropriate installed equipement for flow duct. We would be pleased to provide you with our knowledge also beyond the heat exchanger technology. The precise project In case of a plant for catalytic combustion, the connecting hood to the heat exchanger was significantly shortened due to the assembly of a THERMO-AWT 3-Way Stop valve. After this

Request for a quote

MOMMERTZ GMBH

Germany

The neutralisation unit Neutrakon® is suitable for the neutralisation (increase of the pH value above 6,5) of acidic condensates of gas condensing boilers (heat exchangers) and/or flue gas systems The Neutrakon® Classic Line consists of 4 different units for the neutralisation of acidic condensates of gas condensing heating units from 25 – 300 kW Neutrakon® 01/25 – up to 35 kW Neutrakon® 02/50 – up to 65 kW Neutrakon® 03/150 - up to 150 kW Neutrakon® 04/300 - up to 300 kW

Request for a quote

MOMMERTZ GMBH

Germany

The neutralisation unit Neutrakon® is suitable for the neutralisation (increase of the pH value above 6,5) of acidic condensates of gas condensing boilers (heat exchangers) and/or flue gas systems up to 1000 kW. With booster technology for an increase lifetime. The Premium Line consists of 6 different units for the neutralisation of acidic condensates of gas condensing heating units up t0 1000 kW Neutrakon® N35 – up to 35 kW Neutrakon® N65 – up to 65 kW Neutrakon® N170B - up to 170 kW Neutrakon® N300B - up to 300 kW Neutrakon® N650B - up to 650 kW Neutrakon® N1000B - up to 1000 kW

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EC PLAZA

South Korea

High frequency welded fin tube extendheat transfer surface that provides maximum efficiency in theat exchange applications from exhaust hot gas to a contained liquid process. Both solid and serrated fin tube is used for Heat recovery steam generator, Petrochemical, Boiler Plants, Economnizer, Gas cooler and Heat exchangers in a wide range of applications. Solid fin tube is recommened for contaminated gas streams where oil, coal, wood or other high fouling fuels are used. Serrated fin tube is primarily used in clean streams. Product Specification Bare tube diameter : 15.88 mm ~ 50.8mm Fin pitch : 5 ~ 12 FPI Fin height : 6.35~25.4mml Fin thicknes : 0.3~0.75mm Fim material : Aluminum or Copper Length : 20,000mm(Max.) Our Company First of all, we are very pleased to take the opportunity to introduce you about our company. DRTC is a highly qualified manufacturer of Aluminum fin tubes for AFC and also of Copper Alloy Tube & Pipe and pleasure vessels parts such as tube-sheet.

Request for a quote

NLMK-EUROPE-PLATE

Belgium

Standard : EN 10028-2 / EN 10028-3 / EN 10028-4 / EN 10028-5 ASTM/ASME Our carbon and alloy steels are especially designed to produce large high-pressure vessels. These steel grades are characterized by yield strengths from minimum 235 N/mm² to maximum 460 N/mm² and by good weldability. The fine-grain structural steel grades are suitable for mechanical forming and excellent welding. We deliver these steels as heavy plates or bars, as well hot rolled and forged, so we can cover a wide range of thicknesses and widths. Our specialists can coordinate for you the steel preparation at all stages, to enable you to get your pieces ready to use. Applications : •storage tanks, storage spheres •pressure vessels •boilers •heat exchangers •gas turbines •etc…

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

With the effective recovery of flue gas heat, you can save up to 14% on fuel and, at the same time, reduce emissions. — Effective heat recovery and reduction of flue gas losses — Maximum efficiency gain when using condensing technology — Fuel savings of up to 7%, or up to 14% when using an additional downstream condensing heat exchanger — Intelligent control for a long service life and high level of efficiency — Compactly integrated into the boiler or as a stand-alone version for simple retrofitting — Feed water cooling or combustion air preheating as alternatives to the condensing heat exchanger

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— For continuous feed water control — Increased efficiency of flue gas heat exchangers — Fewer pump circuits — Constant boiler water level — Minimum flow rate for cooling the feed pump is assured Highly efficient boiler systems with perfectly matched boiler house components ensure that low levels of energy consumption and emissions are achieved.

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— For the extraction of the feed water/condensate — Consumes less power, more convenient to operate — Speed-controlled version for increased flue gas heat exchanger efficiency — Redundant pump for maximum reliability of supply — Preassembled for fast installation Highly efficient boiler systems with perfectly matched boiler house components ensure that low levels of energy consumption and emissions are achieved.

Request for a quote

KELVION HOLDING GMBH

Germany

This new addition to our product line is a compact heat exchanger made from high-alloyed stainless steel and can handle temperatures up to 550°C. Its compact and modular design makes it extremely versatile and easy to service. Our exhaust gas heat exchanger is designed to recover heat from exhaust gas produced for example by combustion engines used in combined heat and power plants. The heat exchanger transfers the heat from the exhaust gas to a liquid (water or water-glycol solutions). When heated up, this liquid can be used in central heating systems; for preheating air in the combustion chambers of furnaces and turbines; to dry coal, pulp, wood and other materials as well as for generating electricity with a Rankine process.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Fine Tubes leads the manufacture of precision tubes required in the fabrication of shell and tube heat exchangers. Our heat exchanger tubes are used for the cooling, heating, or re-heating of fluids, gases, or air in a diverse range of industries. Alloys Fine Tubes heat exchanger products are produced as seamless, welded or welded redrawn tubes in the following materials nickel alloys, stainless steels, duplex, super duplex. Please note that we have a minimum order value of £10,000.

Request for a quote

EUROPEM

Belgium

Most of the Europem incinerators are equipped with waste heat recovery systems. Europem has supplied a wide range of waste heat recovery installations including steam boilers, thermal oil boilers, gas-liquid heat exchangers, gas-gas heat exchangers, bath heaters and air heaters. All waste heat recovery installations are tailored to the needs of the client and the optimal design of the overall installation. Our range of waste heat recovery systems include: -Fired tube boilers with or without economizer. Single pass and multi-pass systems can be supplied Boilers can be equipped with an on-line cleaning system to allow operation with dust-loaded (flue) gases Boilers up to 30 MW capacity can be supplied with pressures ranging from 10 to 22 bar. - Single pass and multi-pass systems can be supplied -Water tube boiler boilers with or without economizer Superheated or saturated steam Horizontal or vertical boiler arrangements Bundles in refractory lined casing or with membrane walls Capacities up to 40 MWth with pressures ranging from 15 to 65 bar. – Thermal oil boilers – Bath heat exchangers – Air – flue gas tube and shell heat exchangers – Flue gas – liquid tube and shell heat exchangers – Air heaters Heat exchangers can be manufactured in carbon steel or high grade alloys e.g. Duplex, Hasteloy, Inconel, AISI 316, AISI 304.

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Flat spray pattern with uniform distribution throughout pattern area. Even spray impact across the entire spray area. Applications Cleaning: Automotive, containers, films, felts, filters, screens, bottles, crushed stones, earth and sand, metal parts, machines, steel plates and pieces Spraying: Etchants, oils, lubricants, glues, solutions, insecticides, herbicides Cooling: Gas, smokes, heat exchangers, tanks, steels, roofs Water screen: Fire protection, heat protection, dust suppression, deodorization

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Flat spray pattern with a mountain-shaped spray distribution having gradually tapered edges. Tapered edges overlap to provide uniformity of spray distribution in multiple-nozzle arrangements. Applications Cleaning: Automotive, containers, films, felts, filters, screens, bottles, crushed stones, earth and sand, metal parts, machines, steel plates and pieces Spraying: Etchants, oils, lubricants, glues, solutions, insecticides, herbicides Cooling: Gas, smokes, heat exchangers, tanks, steels, roofs Water screen: Fire protection, heat protection, dust suppression, deodorization

Request for a quote

EUROPE ZHAOHAN VACUUM PUMP CO., LTD

Hungary

Closed circulation vacuum system is consisted with liquid ring vacuum pump and compressor, liquid and gas separator tank, heat exchanger, instrument and valves, internal pipeline, and common base plate. The pumped gas enters the liquid ring vacuum pump/compressor from the pump inlet, after compressed by the liquid ring vacuum pump/compressor, the gas will enter to enter the gas-liquid separator together some of the working liquid. Inside the gas-liquid separator, the gas and liquid are separated, and the gas is discharged from the pump outlet, and the working fluid go from the heat exchanger and enter the liquid ring vacuum pump/compressor for recycling.

Request for a quote

REFRA, UAB

Lithuania

Refra heat exchangers for gas coolers are made of special K65 copper tubes for high pressures which go up to 120 bar. Such coils are perfect for CO2 systems as they are capable of maintaining the pressure these systems need. Standard units are designed using corrugated fin shape and can be made with aluminum, galvanized or stainless steel frame with Aqua-Aero anti corrosion protection. These products are usually selected and manufactured exclusively according to the customer’s wishes.

Request for a quoteResults for

Gas heat exchangers - Import exportNumber of results

73 ProductsCountries

Category

- Heat exchangers (58)

- Boilers, industrial (4)

- Electric motors and parts (3)

- Biogas and biofuel - energy use (2)

- Gas and oil - exploitation (2)

- Nozzles - ferrous metal (2)

- Waste water recycling (2)

- Fittings, pipe, tube and hose - plastic (1)

- Gas - production and distribution (1)

- Industrial maintenance (1)

- Mechanical engineering - custom work (1)

- Pneumatic system components (1)

- Pumps (1)

- Radiators - fin-type (1)

- Vacuum pumps (1)

- Valves for industrial fittings (1)

- Valves for pneumatic equipment (1)

- Wood veneer - machinery and equipment (1)