- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- furnace rollers

Results for

Furnace rollers - Import export

LBI

France

We manufacture rough or fully machined furnace roller in refractory alloy

Request for a quote

CASTSERVICE GMBH

Germany

Draft bound spare parts out of cast and steel

Request for a quote

BRT GRUP ANADOLU METALURJI

Turkey

Produced from stainless steel or other heat-resistant steels through the centrifugal casting method, our rollers are resistant to high temperature, thermal shocks and abrasion depending on the terms of use. Furnace rollers, capable of operating at a furnace temperature of 1,400 degrees, are coated using the thermal spraying method.

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The Datapaq Furnace Tracker Systems for Glass Tempering and Bending from Fluke Process Instruments feature the Datapaq DP5 data logger, low height thermal barriers from our TB75/TB77 range, thermocouples and our intuitive Insight™ Software to create a complete solution. This solution is optimized specifically for the glass tempering process, where the height at the furnace entrance is typically very limited. The system’s unique thermal barrier design includes an exterior ceramic coating to ensure there is no metal contact with furnace rollers. This solution ranges from 29 to 60mm (1.14 to 2.36 in.) high and can be used in temperatures up to 1000°C (1832°F). Data Logger The Datapaq DP5 is the perfect solution for low-height applications like glass tempering due to its size, which can be as low as 11.7mm (0.46 in.) and as narrow as 57 mm (2.24 in.). Once combined with the Datapaq Insight™ Software, you can display information

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Grease lubrication of friction and rolling bearings in the high-temperature range up to 300°C Lubrication of tunnel kiln cars, baking, burn-in and drying furnaces, hot gas units, reaction vessels, boiler plants, roller and conveyor rollers in continuous furnaces, etc. Use at bearing points under influence of chemicals Lubrication of bearings under influence of fuel Advantages and benefits Absolutely resistant to water and steam Resistant to solvents, for example benzene, benzol, acetone, trichloroethylene and against inorganic acids, for example sulphuric acid, hydrochloric acid and nitric acid as well as stearic acids, alcohols and halogens Broad range of applications above the temperature limits of other lubricating greases Excellent wear protection Reduced maintenance and lubricant costs due to possible lifetime lubrication Excellent plastic and elastomer compatibility

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

UNIL LUBRICANTS

Belgium

Grease HT 300 is a grease based on bentone, suitable for use at very high temperatures with peaks up to 250°C. Due to the unique additive package, this grease is remarkably resistant to high pressure, which offers protection under heavy loads. Benefits For use on all machines (except fast-moving bearings) under high temperatures (with peaks up to 250°C), such as in drying furnaces and ovens, transport chain rollers, … Excellent adhesive properties. Not soluble in water.

Request for a quote

CASTSERVICE GMBH

Germany

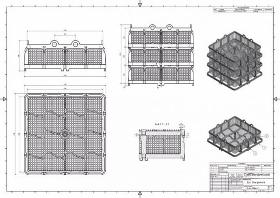

The various requirements in all kind of heat treatment processes will be met with high quality and long living products. In addition to our standard systems we are able to offer individual concepts that are specially designed for your demands. Furthermore, we could support you in choosing applicable material grades as well as developing charging devices. The design of new systems is the day-to-day business of our own Engineering-dept.

Request for a quote

CASTSERVICE GMBH

Germany

Lifting bars, edge angles, facing panels, oven tabs for roller hearth furnaces. The various requirements in all kind of heat treatment processes will be met with high quality and long living products. In addition to our standard systems we are able to offer individual concepts that are specially designed for your demands. Furthermore, we could support you in choosing applicable material grades as well as developing charging devices. The design of new systems is the day-to-day business of our own Engineering-dept.

Request for a quoteResults for

Furnace rollers - Import exportNumber of results

9 ProductsCountries

Company type