- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- full inspection

Results for

Full inspection - Import export

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

The reference information is then applied during service and inspection visits to ensure that the expected performance levels are being met. All inspections are carried out by fully qualified Lipp professionals, who utilise the latest analytics equipment. Efficiency tests can be run on each system and cross referenced – helping highlight any operational issues that may have occurred. This comprehensive analysis further notifies Lipp and the end user which parts of the system may need particular attention or replacement. Qualified Lipp technicians also have the skills needed to deal with more specialised installations, such as anaerobic digestion tanks for biogas production. By providing the same level of technical proficiency as the original installation team, Lipp safeguards the quality level of maintenance activity and the tank itself. Lipp technicians also impart knowledge and training to the end users, so that everyone can become familiar with their system

Request for a quote

D&R RACKING LIMITED

United Kingdom

The benefits of carrying out regular inspections, are not only to comply with HSE legislation but also to reduce the risk of racking related incidents promoting good health and safety within the workplace. During an inspection our personnel will complete a Damage Report, they will then go on to produce a Full Rack Inspection Report which will categorise any damage by risk and issued to you. During an inspection our personnel will complete a Damage Report Sheet, they will then go on to produce a Full Rack Inspection Report which will categorise any damage by risk. D&R Racking’s experience and knowledge of storage systems is second to none. We’ve installed small and simple systems for SME clients and racked out entire warehouse systems for larger clients.

Request for a quote

D&R RACKING LIMITED

United Kingdom

To Comply with Health and Safety guidelines it is required that regular in house inspections be carried out and that a full annual inspection be conducted by a ‘technically component’ person. The benefits of carrying out regular inspections, are not only to comply with HSE legislation but also to reduce the risk of racking related incidents promoting good health and safety within the workplace. During an inspection our personnel will complete a Damage Report, they will then go on to produce a Full Rack Inspection Report which will categorise any damage by risk and issued to you. During an inspection our personnel will complete a Damage Report Sheet, they will then go on to produce a Full Rack Inspection Report which will categorise any damage by risk. D&R Racking’s experience and knowledge of storage systems is second to none. We’ve installed small and simple systems for SME clients and racked out entire warehouse systems for larger clients.

Request for a quote

MAINTENANCE PARTNERS

Belgium

Overhauls & Repairs of Turbo Expanders Maintenance Partners has a broad experience in overhauling and repairing turbo expanders: Single stage radial and axial turbo expanders Multi stage axial turbo expanders Single stage axial turbo expander wheels directly connected to axial compressor – can be in combination with an abradable sealing upgrade to the compressor for increasing efficiency These turbo expanders are utilised in the following applications: Chemical and petrochemical industries Fluid Catalytic Cracking (FCC) Residue Fluid Catalytic Cracking (RFCC) Nitric Acid Acetic Acid Terephtalic acid, or PTA Natural gas and oil industry Pipeline pressure reduction LNG, LPG Liquefaction of methane Coal gasification and hydration General industrial power recovery for example blast furnace top gas expansion Turbo Expander Activities Our services on turbo expanders include: Standard minor inspections Full comprehensive overhauls Re-blading Complete new rotor...

Request for a quote

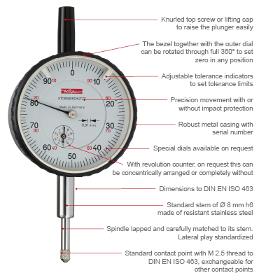

KÄFER MESSUHRENFABRIK GMBH & CO. KG

Germany

The well thought-out design, accurate components and robust construction of our Precision Dial Gauge series offer reliability, durability and long working life. The standard features that enhance the quality across our entire product range are: Calibrations of all Dial Gauges are traceable to national and international standards. The final quality control for the whole series includes visual inspection and full mechanical functional tests. Supplied with Declaration of Conformity and Confirmation of Traceability. Materials and components selected specifically to ensure a long working life.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BLASQEM, LDA.

Portugal

We offer a full range of inspection and control equipment, mainly related to sandblasting / shot blasting, to ensure compliance with regulations and ensure process efficiency, in particular to assess: Surface condition; Degree of cleanliness of the surface; Surface roughness; Sandblasting parameters; Layer thickness; ...

Request for a quote

MIMOSA S.R.L.

Italy

Antiembolism full length stocking with inspection hole, adjustable top, ambidextrous. Comp: 82% Polyamide, 18% Elastane

Request for a quoteResults for

Full inspection - Import exportNumber of results

8 ProductsCompany type