- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- friction motors

Results for

Friction motors - Import export

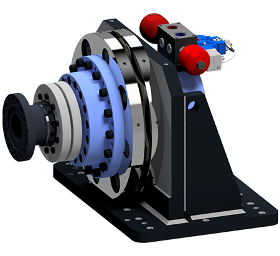

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

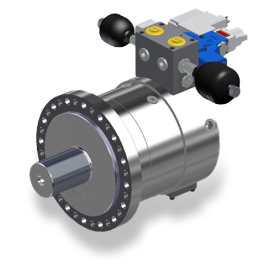

The output shaft of the HSH swivel motors has radial and axial hydrostatic bearings. Here, radially and axially arranged bearing pockets are supplied with pressurized oil via a separate pressure connection. As a result, the output shaft is centered radially and axially between liquid cushions and all metallic contact surfaces are permanently separated from each other by a thin liquid film. This eliminates wear caused by metallic friction in any operating state, even at zero speed compared to hydrodynamic plain bearings. In conjunction with highly dynamic control valves and angle of rotation sensors, these actuators are preferably used in controlled systems in which disturbance variables such as friction and the stick-slip effect must be reduced to a minimum. Furthermore, due to the lack of internal seals, they are ideal for test series with large numbers of load cycles where an interruption, e.g. due to the replacement of internal seals, is not permitted.

Request for a quote

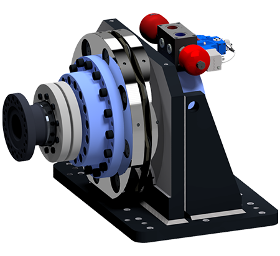

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

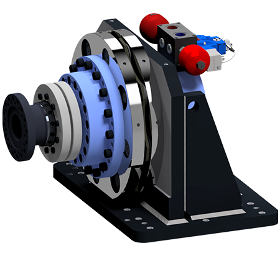

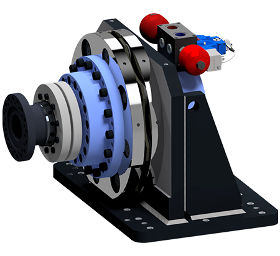

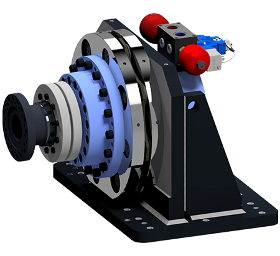

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quote

STRONG ENERGY COMPANY

Turkey

High-performance, low friction fully synthetic motor oil designed for long-term use in modern motors.The combination of ultimate synthetic oil technology with latest additive generation (mid SAPS technology), guarantees a low viscosity,highlyshear resistant engine oil that is sure to prevent deposit build-up, lower friction loss in the engine and provide optimal wear protection.

Request for a quote

STRONG ENERGY COMPANY

Turkey

High-performance, low friction fully synthetic motor oil designed for long-term use in modern motors.The combination of ultimate synthetic oil technology with latest additive generation (mid SAPS technology), guarantees a low viscosity,highlyshear resistant engine oil that is sure to prevent deposit build-up, lower friction loss in the engine and provide optimal wear protection.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Precise, reliable measurements of both static and dynamic torques in either direction can be made with this range of sensors. This opens a wide range of possible applications to the user. These torque sensors are standard equipment in a wide range of industrial automation, quality control and automotive components industry applications, as well as in laboratories. Typical applications: Screwing technology — Checking and adjusting bolting tools such as torque limiting wrenches, screwdrivers — Testing bolted connections Measuring the drag torque of motors and pumps — Frictional torques of gears, bearings and seals — Testing torsion springs — Adjusting equipment in the automobile industry (sunroof, power windows etc.) Strain gauges are mounted on the torsion shaft of the sensor element, itself made of steel, connected to form a full bridge.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

For closed gear units and geared motors, plain and friction bearings even at higher rotating speeds, e.g. on filling and packaging machines For joints, propeller shafts and chains when grease lubrication is specified Advantages and benefits Toxicologically harmless as defined in German LFGB Formula in accordance the FDA guideline 21 CFR 178.3570 NSF H1 registered Long operating times due to good resistance to oxidation and ageing Reduced wear due to highly adhesive, load-bearing lubricating film Excellent corrosion protection Low dynamic viscosity enables use with minimal bearing play and gear unit spaces Good pumpability with central lubricating systems Very high resistance to hot and cold water, watery-alkaline and acidic disinfectants and cleaning agents

Request for a quote

LUTZ PUMPEN GMBH

Germany

The B80 KGK G3 series is a powerful and robust submersible centrifugal pump with plain bearings, drive lantern mounted on anti-friction bearings and IEC standard motor. The B80 KGK G3 series is designed in single or two-stage versions with one or two impellers for high flow rates. Multistage pumps are used to increase the delivery pressure while maintaining compact hydraulic dimensions and are used in particular in processes with high delivery pressures at low flow rates. They are perfectly designed for industrial use in closed unpressurized tanks, basins or pits. * suitable for flow rates up to 270 m³/h * equipped with a suction strainer as standard * a suction pipe extension up to 2000 mm is possible * available in immersion depths from 500 - 4000 mm Features & Advantages * vibration and oscillation free operation * Efficient and space-saving design due to 1- and 2-stage pump hydraulics * Long operational reliability

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quote

TECNORULLI S.R.L. CON SOCIO UNICO

Italy

Steel rollers or with polyamide resin sectors driven by tangential chain or chain with links in series.The jacket is composed of an austenitic stainless steel tube AISI 304 (on request, AISI 316, etc. …) with a constant thickness or cylindrical polyamide resin sectors reinforced with glass microspheres. The axle is made of drawn austenitic stainless steel round AISI 303 (on request. AISI 304, AISI 316, etc. …) They are used in motor-driven conveyors and in motor-driven conveyors for stockpiling with medium-high loads and medium speeds, in bad environmental conditions.In order to facilitate installation, TECNORULLI provides brackets for mounting on the structure. Operating temperature, TN:-10÷+90[°C]

Request for a quote

ERC ADDITIV GMBH

Germany

ERC motor oil power additive with friction modifier reduces friction, wear, and sediments. It also improves the oil supply and stabilises viscosity with reduced oil sludge formation. All these features contribute to improved engine performance. THE EFFECT With the ageing of oil in everyday engine operation, build-up and clogging of filters and oil passages occur. ERC motor oil power additive removes this deposits, improves the oil supply, and protects metal surfaces. THE ADVANTAGES AT A GLANCE - Reduces friction and wear and increases engine performance - Cleans build-up off the engine and oil passages - Safeguards and improves oil supply - Reduces noises and stabilises oil pressure - Protects against oil ageing and corrosion - Reduces fuel consumption and exhaust gases - Extends engine service life

Request for a quote

SCHNEIDER - POWERTOOLS - HP CLEANERS - INDUSTRIAL WET & DRY VACUUM CLEANERS

France

125mm disc diameter, cutting depth 30mm, no load speed 10000 tr/min, 75.8 dB noise level. Delivered with 4Ah or 5Ah (option) with tool bag. Brushless, so less friction with the motor therefore more efficient and less wear-and-tear.

Request for a quote

SCHNEIDER - POWERTOOLS - HP CLEANERS - INDUSTRIAL WET & DRY VACUUM CLEANERS

France

Our multi-purpose (ref 50505) Hammer Drill/Driver 60Nm 20V Brushless Technology 2 speeds is your daily professional tool. Multipurpose and robust with a metal self-tightening drill chuck of 13mm. It drills Steel (13mm), concrete (13mm) wood (45mm) at 500-2000tr/min with max torque of 60Nm. Brushless, so less friction with the motor therefore more efficient and less wear-and-tear.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Friction motors - Import exportNumber of results

17 ProductsCountries

Company type