- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- freeze drying - machinery and equipment

Results for

Freeze drying - machinery and equipment - Import export

FRIGORTEC GMBH

Germany

The POWDRYER™ PD08 metal powder dryer is used to dry inorganic metal powder for the complex additive manufacturing (3D printing) process. It corrects the manufacturer’s fluctuating metal powder qualities, thus optimizing the metal powder’s flowability. It also reduces the number of air inclusions in finished workpieces. Significantly higher material densities are the result. Fields of application > Particularly for metal printing products where maximum strength is required > For the printing of alloys of aluminium, titanium, tool steel, etc. > Special tools for the metal-processing industry, machine and system engineering, prototype development, and more > Aviation, aerospace, and automotive industries, plus medical and dental technology

Request for a quote

TURKEYRAF

Turkey

Maximizes heat transfer with D Form aluminum pipe winding, provides extraordinary performance with 71mm insulation thickness. Dust-proof condenser does not require maintenance, it is long-lasting thanks to its aluminum frame and electrostatic powder painted and galvanized coated inner and outer body. Apple Series with its negative (Static), positive (dynamic) or dual regime options and large volume, provides minimum energy consumption. Apple is suitable for installation types such as singular, block and land, and allows you to create different layouts in the Market.

Request for a quote

BIOPHARMA GROUP

United Kingdom

The Lyostar3 operates a cutting edge R&D system, moving users away from the ‘trial-and-error’ elements during the development processes, toward unique SMART technology that enables fast and easy optimisation of cycles, and ensure the smooth transfer from laboratory- to production-scale. Independent studies have confirmed the use of SMART Freeze Drying Technology™ software from SP Scientific (available with the Lyostar), has offered a time reduction on an average cycle development in the order of 78%. The technology reduces the average cycle development to one or two runs, rather than the conventional series of six to eight runs – thereby not only reducing development time, but also lowering materials costs by at least one third.

Request for a quote

BIOPHARMA GROUP

United Kingdom

Unequalled for design and capabilities, the Genesis is the most versatile freeze dryer for pilot, research or small scale production applications. Its advanced product monitoring and process control make it ideal for research and with a user-friendly interface it is perfect for laboratories with multiple products or formulations to investigate. An ergonomic layout allows easy inspection of the vacuum pump and facilitates oil changes, which can be made quickly and cleanly in the laboratory environment. Genesis is available with up to six bulk drying shelves (five vial processing shelves). An expanded range of shelf arrangements, available with a shelf latching kit, allows you to configure it to process a wide variety of vial sizes.

Request for a quote

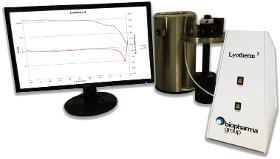

BIOPHARMA GROUP

United Kingdom

Frozen state solutions are a critical product stage or end product in a variety of industries, including freeze drying, pharmaceuticals, food storage and biotech. The Lyotherm3 combines electrical and thermal techniques. This unique dual analysis adds a new dimension to the data of this critical stage. Impedance Analysis (Zsinφ) is a fixed frequency dielectric analysis providing an indication of the sample tracks molecular mobility, including events not picked up by thermal methods like DTA or DSC Differential Thermal Analysis (DTA) measures the difference in temperature between a sample and a reference, highlighting exothermic and endothermic events e.g. crystallisation, eutectic melting and glass transitions Combining DTA and Impedance analysis means Lyotherm is more sensitive to changes within the frozen structure than other exclusively thermal techniques.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BIOPHARMA GROUP

United Kingdom

Every freeze-drying formulation has a critical temperature, below which it should be maintained during primary drying in order to prevent processing defects. The Lyostat freeze drying microscope allows observation of the sample structure during drying and heating so that the exact point of collapse can be determined. Innovative lighting and image capture systems (with articulated head for easy sample loading) provide sharp visualisation for easy, accurate identification of structural changes.

Request for a quote

BIOPHARMA GROUP

United Kingdom

Benchtop Pro are compact research freeze dryers that encompass a range of lab processing requirements.They are flexible, powerful and user-friendly. Condenser temperature options from -55°C to -103°C to enable processing a wide range of products and solvents Extensive range of accessories allows for any shape or size sample to be freeze dried including trays, flasks, ampoules, vials and 96 well microtiter plates Range of manifolds in clear acrylic or stainless steel for superior corrosion resistance Precise vacuum control enables you to achieve better, more repeatable results. One-button auto start-up and shut-down activates all operating parameters in a correct and safe sequence, protecting the product and equipment Hot gas defrost and smooth-walled condensers for fast turnaround and minimal delay between runs

Request for a quote

GLOBUS CONTAINER - A. DIMTSIOS P.C.

Greece

PTI checked, wwt, cw, csc plated.

Request for a quote

GLOBUS CONTAINER - A. DIMTSIOS P.C.

Greece

PTI checked, wwt, cw, csc plated.

Request for a quote

MIRAI INTEX

Czech Rep.

MIRAI Cold 80 T operates in a closed cycle as an indirect refrigeration system with Air as a refrigerant. The machine comes with a factory-equipped heat exchanger which is optimized to work with silicone oil (also compatible with other working fluids). The system is a standalone unit that requires minimum servicing and maintenance.

Request for a quoteResults for

Freeze drying - machinery and equipment - Import exportNumber of results

11 ProductsCompany type