- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- welding machines

Results for

Welding machines - Import export

DOREY

France

The automatic welding machine P2 is the innovative successor of the successful P models and an efficient and manoeuvrable device for welding truck tarpaulins, tents, awning materials and advertising banners. It produces optionally 20, 30, 40 and 45 mm wide overlap welds and may also be converted for welding in welting ropes. In addition, by mounting hem welding accessories, the automatic machine can without any difficulty be used for the production of 20 mm, 30 mm, 40 mm and 45 mm hems. The heat output of up to 4000 W 230 V AC is infinitely variable from 20 to 700 °C for an individual adjustment to different materials. The P2 starts automatically after the weld head has been swivelled in. In addition, the infinitely variable speed adjustment of the modern generation of motors with their performance of up to 18 m/min., in conjunction with the holding down device for crease free welding, makes for an optimum welding result.

Request for a quote

STEEC

France

The nuclear sector is one which requires extreme precision as well as the ultimate discipline. This also includes machining of course. STEEC provides the players in this sector high-tech subcontracting solutions in micro-drilling or conventional micro-machining and laser micro-cutting. Major French and European companies in the nuclear sector put their trust in STEEC for the manufacture of micromechanical parts.

Request for a quote

STEEC

France

Thanks to its very-high precision maser micro-cutting STEEC is able to provide high quality services that can be applied in watchmaking. In fact this very high precision industry, which is subject to very stringent demands requiring cutting precision down to one or two microns… The company stands out from its competitor through its high degree of responsiveness in the field of micro-machining. Working with STEEC in laser micro-cutting or in micro spark erosion guarantees that you will receive you parts in time with complete peace of mind.

Request for a quote

STEEC

France

STEEC has been a pioneering company in cutting and laser micro-cutting in France. Since the first YAG industrial laser in France was installed in the premises of the company in 1983. 30 years ago STEEC developed unique know-how and competence in this field which it offers its customers as part of its subcontracting service. The company now has 5 laser cutting machines which enable it to meet a wide range of requirements. These machines, in which the company continually investing, have been custom designed according to STEEC specification in order to comply with the quality and precision standards demanded by the customers. Using its highly efficient innovating machines STEEC carries out very high precision cutting on flat and tubular parts with thickness ranging from 3mm to 2µm !

Request for a quote

ELINNOV CONNECT

France

The SWIFT K33 is one of the high-end core-to-core optical welders, perfectly adapted to the Job of the installation. With a large 5-inch touch screen and a high-performance oven, it allows fiber connections in less than 20 seconds (weld + oven). It is compatible with the majority of 250 µm and 900 µm fibers, and pigtails and is also compatible with SOC connectors

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

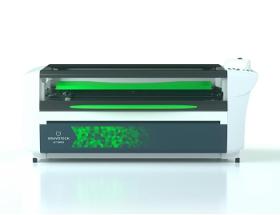

GRAVOTECH

France

SIGN ENGRAVING AND CUTTING MACHINE With a working area of 610x305mm exactly matching ¼ sheet size, the LS100EX is a signage engraving and laser cutter above the rest1. Be it plastic, wood, metal, or glass, any signage material can be engraved and cut. This can be your favorite sign making machine, with a large range of consumables available with up to 2 color layers, for a contrasted and professional result. INDUSTRIAL LASER FOR SERIES PRODUCTION The large dimension combined with a gantry laser technology makes the LS100 EX the perfect CO2 laser machine for small production series. Load your items or parts to be engraved, and create your engraving job with the Gravostyle software. Several industrial functions are available, such as the Matrix mode or automatic date stamp. 2 LASER SOURCES AVAILABLE The LS100 EX is available with a CO2 laser source or a Fiber laser source, to match all of your applications.

Request for a quote

GRAVOTECH

France

LARGE MARKING POSSIBILITIES With its 3-sided door, the LW3 benefits from the best inside height dimensions and can securely envelop and mark parts up to 628 mm high. Thanks to its compatibility with our Fiber, Hybrid, Green industrial laser series, the LW3 can mark with high precision nearly every metal or plastic surfaces on its special positioning table. VERSATILE From unique identification marking, to multi-level engraving, and matrix marking on a batch of small to medium parts, this industrial laser station can mark your large part at several positions, and levels. Add a 3D module to your LW3 laser to mark sloped parts. INDUSTRY ORIENTED This laser marking machine is the only large laser engraver of the market with an attached touchscreen allowing the operator to easily manage the direct part marking process. In addition to the easy installation, manutention, and silent/ergonomic door opening, this class 1 laser stands out with its exceptional build quality.

Request for a quote

DOREY

France

The PFAFF 8301 uniquely combines all the physical advantages of ultrasonic welding with the whole range of technological sewing experience. On the PFAFF 8301 the workpiece is held between the sonotrode and the anvil wheel and welded continuously under pressure. When welding continuously by the ultrasonic method, the material to be welded will be subjected to rapid chan- ging pressure vibrations. The heat develops because of molecular vibrations beneath the material surface, for thin materials within the immediate vicinity of the actual weld.

Request for a quote

DOREY

France

Ultrasonic welding machines of the Seamsonic series combine all the physical advantages of ultrasonic welding with the whole range of technological sewing experience. On the PFAFF 8301/8310/8312 Seamsonic the workpiece is held between the sonotrode and the anvil wheel and welded continuously under pressure. When welding continuously by the ultrasonic method, the material to be welded will be subjected to rapid changing pressure vibrations. The heat develops because of molecular vibrations beneath the material surface, for thin materials within the immediate vicinity of the actual weld.

Request for a quote

DOREY

France

With the new 8311, PFAFF INDUSTRIAL introduces a new generation of ultrasonic welding machines. With more than 30 years experience in rotary ultrasonic welding, the engineers at PFAFF have successfully developed this process even further. In addition to the regulation of speed and welding energy, the new 8311 allows the force measured during welding to be measured and kept constant - a true world first and a quantum leap in textile ultrasonic welding. Adjusting and handling the machine becomes much easier. The process becomes clearer, more reproducible and easier to understand. In short, the machine is taken to a new level.

Request for a quote

DOREY

France

Ultrasonic welding machines of the Seamsonic series combine all the physical advantages of ultrasonic welding with the whole range of technological sewing experience. On the PFAFF 8310 the workpiece is held between the sonotrode and the anvil wheel and welded continuously under pressure. When welding continuously by the ultrasonic method, the material to be welded will be subjected to rapid changing pressure vibrations. The heat develops because of molecular vibrations beneath the material surface, for thin materials within the immediate vicinity of the actual weld. Ultrasonic welding with the Seamsonic is a modern, innovative and economic alternative and complementary to conventional sewing technology. If assembling of laminates, clothing fabrics with high share of polymer and technical nonwovens is required and in particular to get, the use of the Seamsonic is the first choice.

Request for a quote

DOREY

France

The new Miller Weldmaster T300 Extreme combines heat, speed, pressure and precision with precise positioning of the weld head for increased efficiency and speed with an ergonomic design. With 4 positions and 3 arms integrated into one machine, you have the versatility to make almost any product. Larger, rotating/tilting, easy to use screen Available in hot air, hot iron, or both for greater product versatility Precision sealing head with three synchronized controls for increased efficiency and higher speeds. Test mode allows the operator to quickly find the optimal heat and speed setting for the machine. Adhesive tape dispenser included to easily apply Velcro weld and extruded profiles to any product. Built-in material extractor to reduce labor or long weld seams.

Request for a quoteResults for

Welding machines - Import exportNumber of results

13 ProductsCompany type