- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- threaded pins

Results for

Threaded pins - Import export

NORELEM FRANCE

France

Hardened and ground (HRC 60 ±2). Note: The locating pins are designed to make the joining process easier. Used in combination with hardened locating bushes 02026, they enable exact, low-wear, and fast changes of the workpiece. Versions D1 = 5 and D1 = 6 do not have an internal thread. Drawing reference: Form B: cylindrical pin Form C: rhomboid pin

Request for a quote

NORELEM FRANCE

France

The rest pads can be used both as a stable and precise support and as a stop. The pin form of the rest pad also allows it to be used with components with constricted support points.

Request for a quote

NORELEM FRANCE

France

Tapped cylindrical pins are chiefly used in blind holes. The milled flat prevents air compression in blind holes. The tapping makes it possible to use the extractor 03328.

Request for a quote

NORELEM FRANCE

France

Body aluminium. Other metal components steel. Plastic components PA6. Version: Body natural tone anodised. Other metal components trivalent blue passivated. Note: Sliding stop for profile systems type B, type I, and DIN 650 T-slots. Locked by turning the star grip. Sprung threaded pin ensures smooth sliding without tilting the slot key when loosened.

Request for a quote

NORELEM FRANCE

France

Steel version: Grub screw and indexing pin steel. Stainless steel version: Indexing pin hardened: Threaded sleeve 1.4305. Indexing pin 1.4034. Indexing pin not hardened: Threaded sleeve 1.4305. Indexing pin 1.4305. Mushroom grip black grey thermoplastic. Version: Steel version: Threaded sleeve, black oxidised. Indexing pin hardened, ground and black oxidised. Stainless steel version: Threaded sleeve, bright. Indexing pin hardened, ground and bright. Indexing pin not hardened, ground and bright. Note: Indexing plungers are used to prevent any change in locking position due to lateral forces. A new locking position can only be set after the pin has been manually disengaged. Form C or D is recommended for applications where the plunger remains disengaged over a long period and the pin should be prevented from springing back.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NORELEM FRANCE

France

Individual filled gas springs are excluded from replacement. Gas springs are maintenance-free, self-contained systems that are filled with nitrogen under high pressure. For end-of-travel damping and lubrication, a defined amount of oil is also contained inside. The gas springs contain a nonreturn valve in a threaded pin on the pressurised pipe, which allows the pushing force to be lowered at a later time. Gas pressure springs in the sizes 04/12 and 06/15 must be stored and installed with the piston rod extending downwards. As of size 08/19, storage and installation in any orientation is possible. Keep in mind, however, that end-of-travel damping is effective only when the piston rod extends downwards. As a consequence of the physical properties when filling a gas spring, a tolerance range of ±5 % results for the rated pushing force. Gas springs are filled with nitrogen under high pressure and under no circumstances should they be opened or overloaded.

Request for a quote

NORELEM FRANCE

France

Stainless steel version Indexing pin not hardened: Threaded sleeve 1.4305. Indexing pin 1.4305. Mushroom knob black-grey thermoplastic. Version: Steel version: Indexing pin hardened, ground, black oxidised. Stainless steel version: Indexing pin not hardened, ground, bright. Note: Indexing plungers are used to prevent any change in position due to lateral forces. A new locking position can only be set after the pin has been manually disengaged. Form C or D is recommended for applications in which the pin is disengaged over extended periods and should be prevented from springing back.

Request for a quote

ERO JOINT .TANALS

France

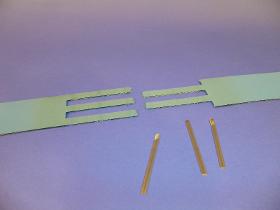

The mechanical fastening system ERO Joint® is available in conveyor belts with a thickness over 1mm. The assembly is made by threading of 3 transversal pins (stainless steel or polyacetal pins can be used). ERO Joint® splice is integrated into the conveyor belt, with no structural, width and colour changes. Tensile Kevlar cord can be embedded in Polyurethane upon request. Anyway using ERO Joint® conveyor belts ensure you a complete freedom and a high-flexibility: no specific tool, no splicing and welding procedure to respect, no deburring, no risk to miss the welding. ERO Joint® conveyor belts are easy to assemble.

Request for a quote

ERO JOINT .TANALS

France

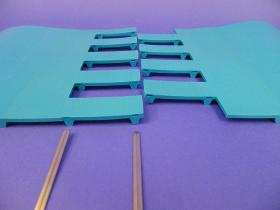

The mechanical fastening system ERO Joint® is available in flat belts with a thickness over 1mm containing an intermediate layer of Polyurethane. The assembly is made by threading of 3 transversal pins. Anyway using ERO Joint® flat belts ensure you a complete freedom and a high-flexibility: no specific tool, no splicing and welding procedure to respect, no deburring, no risk to miss the welding. ERO Joint® flat belts are easy to assemble. Advantages are a fast and easy installation and assembly. With this new lacing technology, you will save time and optimize your production downtime by reducing the repair time.

Request for a quote

ERO JOINT .TANALS

France

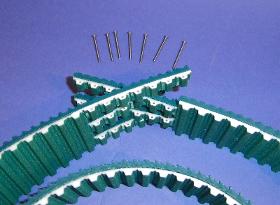

The mechanical fastening system ERO Joint® is available on pitches T10, AT10, T20, AT20, 8M, 14M for all widths over 16mm with reinforcement Steel, Kevlar or Stainless steel. (The recommended minimum diameter for pulleys is 50mm). The ERO Joint® splice is compatible with all type of coatings (Supergrip, Linatex®, PU, Sylomer®, …) and all types of guiding. ADVANTAGES Advantages are a fast and easy installation and assembly. With the pin mechanical fastening system ERO Joint®, you will optimize your production downtime by reducing the repair time. The assembly can be realized by screwing or with a tool. This tool enables the pre-tension of belt and makes pins threading easier. ERO Joint ® Ultimate version In Ultimate version, the mechanical belt fastener ERO Joint® transmits more than 50% of the power of a Flexbelt (true endless belt): Between pulleys, there is always a ½ continuous tight side to assure the mechanical resistance and the rigidity of the belt.

Request for a quote

SPM - SOCIÉTÉ PYRÉNÉENNE DE MÉTALLURGIE

France

DRILLSTAR is licensed by API and VAM for the manufacture of standard and premium threads (box and pin). The whole range of casing and tubing accessories (Cross-over, pup joints, flanges, plugs, nipples, locators...) can be manufactured and delivered worldwide on short notice.

Request for a quote

SPM - SOCIÉTÉ PYRÉNÉENNE DE MÉTALLURGIE

France

Drillstar taper taps and die collars are manufactured from high-grade alloy steel and cemented to ensure the highest strength. They are available in a wide range of sizes, and can be equipped with different types of guides. Taper Taps Plain type Drillstar taper taps are either plain or fluted, with four longitudinal grooves which allow the easy evacuation of cuttings. The hardened cutting teeth (wickers) are available with either right-hand or left-hand spiral. Over a meter in length, the taps offer two particular advantages : First, they can be screwed into the washover subs, thus allowing the tap to be guided by an external tube. Secondly, due to the fine tapering of the threads, the tap can be screwed further into the fish head and will accept considerable pull without releasing the fish. Skirted type For difficult fishing operations, Drillstar Industries has developed a skirted taper tap. This rugged tool is composed of 3 pieces : 1.A taper tap with an upper pin thread. 2.A sk

Request for a quoteResults for

Threaded pins - Import exportNumber of results

13 ProductsCountries