- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- positioning systems

Results for

Positioning systems - Import export

NORELEM FRANCE

France

Body and rotary table Al alloy, anodised. Spindle steel, casehardened. Spindle bearing maintenancefree. Position indicator plastic. Version Radial play of rotation axis < 0.015 mm. Axial play of rotation axis < 0.02 mm. Repeat accuracy < 0.05°. Spindle selflocking. Note 360° adjustment with no end stop. The position indicator displays in 0.1° increments clockwise. The angle of rotation is indicated directly on the large LCD display. The rotary stage rotates anticlockwise. Reset, chain dimension and offset settings can be made via the keypad. 2 years battery life. The battery is quick and easy to replace. The mounting position of the position indicator is set in 4 positions using one screw. Transmission ratio 211611008 = 501 211611012 = 551 211611025 = 501 The modular design enables the rotary stage to be easily combined with other items of the same size. Drawing reference Assembly position of position indicator a) top (standard) b) right c) bottom

Request for a quote

NORELEM FRANCE

France

Body and rotary table Al alloy, anodised. Spindle steel, casehardened. Spindle bearing maintenancefree. Version Radial play of rotation axis < 0.015 mm. Axial play of rotation axis < 0.02 mm. Repeat accuracy < 0.05°. Spindle selflocking. Note 360° adjustment, no end stop. Scale graduation is 10 increments. Transmission ratio 2116008 = 501 2116012 = 551 2116025 = 501 The rotary stage can be easily combined with other modules of the same size. Drawing reference All counterbores to DIN 74Bm (D6)

Request for a quote

NORELEM FRANCE

France

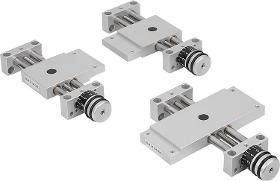

Bearing block and carriage aluminium alloy, anodised. Guide columns stainless steel, ground. Spindle stainless steel, rolled thread. Guide bearing maintenancefree. Version Radial play on guide < 0.02 mm. No axial backlash. Spindle selflocking, with additional lock. Note The almost playfree guides and absolutely playfree spindle allow for adjustment without the need to loosen or clamp the spindle. The scale graduation is in 5 or 10 increments; 1 increment corresponds to 0.1 mm of travel. The cross stage can be easily combined with positioning stages, vertical stages and other accessories of respective size by the modular principle.

Request for a quote

NORELEM FRANCE

France

Bearing block and carriage aluminium alloy, anodised. Guide columns stainless steel, ground. Spindle stainless steel, rolled thread. Guide bearing maintenancefree. Position indicator plastic. Version Radial play on guide < 0.02 mm. No axial backlash. Spindle selflocking, with additional lock. Note Due to the practically playfree guides and absolutely playfree spindle, loosening or clamping of the spindle is not required during adjustments. Digital position indicators with 0.1 mm display accuracy, digits increase with right rotation. The display value of the position indicator can be adjusted by turning the carrier ring. The mounted position of the position indicator can be set in 4 positions with a screw. Within the respective sizes, the positioning stages can be easily combined using the modular principle. Drawing reference Assembly position of position indicator a) top (standard) b) right c) bottom d) left

Request for a quote

NORELEM FRANCE

France

When the positioning cone and bush are mated, the balls are pressed together within the rubbers elastic range and thus locate the two parts in which they have been fitted, with maximum accuracy. To ensure that the rubber in which the balls are embedded is deformed within the elastic range, one must merely ensure that the depth of the hole into which the positioning bush is later pressed is precisely observed. The positioning cone is supplied ready to fit into the positioning bush and must simply be fitted into the counterpart component. Henceforth, a precise zero point positioning system is in place.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NORELEM FRANCE

France

Case-hardened. Toleranced diameter ground. Note: These centring pins are suitable for the central holes of our workholding elements 01148, 01263, 01265, 01267 and 01850.

Request for a quote

NORELEM FRANCE

France

Ball end locating pins are specially designed to ease the locating process. The tendency to jam, caused by the locating hole not being at right angles to the pin or by the pushing force not being parallel to the pin axis, is minimized by the ball-end form (see illustration).

Request for a quote

NORELEM FRANCE

France

Hardened and ground (HRC 56 +2). Note: The locating pins can be easily removed with an extractor.

Request for a quote

NORELEM FRANCE

France

Flange plate, piston and body rust-resistant, bright. Screws electro zinc-plated. Collet red or clear anodised. Note: Machinable collet system with base plate for mounting on 50mm pitch grid plates. The flange plate can be used for external or internal clamping collets. The contour of the workpiece to be clamped is machined into the collet. Free-form and asymmetrical contours can be clamped. The integrated spring package generates a clamping force of 5.8 kN. The clamping force can be raised to 43.5 kN by pneumatic post-clamping. The clamp is released by blowing compressed air onto the lower piston surface pushing the piston upwards and releasing the clamping force on the collet. Clamping travel 0.2 mm. Repeat accuracy < 0.01 mm. Accessory: Collet for external or internal clamping 03179

Request for a quote

NORELEM FRANCE

France

Base and rotary table aluminium alloy. Hollow shaft stainless steel. Preloaded worm gear steel. Claw coupling aluminium with polyurethane coupling spider. Version Aluminium alloy anodised. Note for ordering The unit is supplied with the position of cable outlet or control unit as shown in the drawing. Note Rotary positioning stages for motorised adjustment and positioning tasks. The preloaded worm gear runs virtually playfree. The bearing of the worm shaft offers maximum radial rotational accuracy. Cables can be routed through the large bore in the hollow shaft. The adjustable positioning ring is used to determine the rotational reference point to the position of the assembled part. Proximity switches can be mounted with the optionally available sensor holder (21094). The suitable programming software and interface cable for the stepper motor with positioning control are available as accessories (2500015).

Request for a quote

NORELEM FRANCE

France

Bearing block and carriage aluminium alloy. Guide column and threaded spindle stainless steel. Plain bearing for guide columns and spindle nut highquality special plastic. Claw coupling aluminium with polyurethane coupling spider. Version Aluminium alloy anodised. Stainless steel hardened and ground. Threaded spindle with ball bearing. Note for ordering The unit is supplied with the position of cable outlet or control unit as shown in the drawing. Note Positioning stages for motorised adjustment and positioning tasks. The plain bearings and spindle nuts are suitable for dry running, however lubrication with a grease for plastic plain bearings is recommended. The suitable programming software and interface cable for the stepper motor with positioning control are available as accessories (2500015).

Request for a quote

NORELEM FRANCE

France

Housing plastic. Screen LCD display. Version Position indicators with integrated battery compartment. Plugin sensor. Lowpower LCD with decimal and fraction inch function. Note Digital, mainsindependent measurement display for playfree position detection. The system is often used in industry and trade for measuring tasks on length and angle stops (on panel saws, sheet punches, press breaks...). The recommended dimensions for switchboard installation are 92+0.8 x 45+0.6. The angle display is programmable. The display is ~13 mm high and scaleable from 1999999 to 1999999. The max. display accuracy is 10 µm decimal to 1/64 inch. The position indicator features a batterybacked memory and a battery monitoring system with a LowBatt symbol at <1.1 V. The battery is easy to change via the battery compartment. Energy is supplied via 2 mignon AA batteries (not supplied).

Request for a quote

NORELEM FRANCE

France

Housing hardened and black oxidised. Contact faces ground. Note: This positioning and clamping system is especially suitable for installation in fixtures (plates, clamping tower blocks, etc.) in all mounting positions. The modular design allows the number of and distance between the locating cylinders to be ideally adjusted to suit the clamping task. Due to the small diameters, the spacing between the locating cylinders can also be reduced. The 3 clamping balls are mechanically released through control of the locating cylinder with the "opening" connection. The 3 clamping balls move inward and the fixture can be changed quickly. For clamping, the air is taken from the "opening" connection and the "clamping" connection then receives air on the locating cylinder. The 3 clamping balls are mechanically driven outward again and the new fixture is clamped. To achieve optimal retaining force, the locating cylinder remains connected to the air.

Request for a quoteResults for

Positioning systems - Import exportNumber of results

14 ProductsCompany type