- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- reduce vibration

Results for

Reduce vibration - Import export

NORELEM FRANCE

France

Polyethylene PEUHMW (ultrahigh molecular weight polyethylene). Glide rails for roller chains as defined in DIN ISO 606. These support and guide the roller chains on the return side, thus extending useful life by significantly reducing wear on the roller chains. They reduce vibrations and noise in the chain drive. These glide rails have high abrasion and wear resistance. They are maintenancefree, acidproof and have high chemical resistance. The additional C profiles are used for fastening to the system substructure and they protect the glide rails from lateral forces and torsion. Assembly The glide rails are pushed into the C profiles fastened to the system. The glide rails must be mounted so that the material is allowed to expand. A property of thermoplastic materials is that they expand or contract more than metals when there are temperature variations.

Request for a quote

PATRY

France

The Valex elastomeric pads are designed for the elastic fastening of overhead crane rails. The Valex elastomeric pads, when used with Valex series clips, greatly reduce vibration and consequent rail wear. They lead to a uniform distribution of the loads over the supporting structure. The use of elastomeric padding is particularly advisable where: • the rails are subject to difficult working conditions, • the rails are subject to very large vertical or lateral loads, • the rails are exposed to weathering, • noise and vibrations are to be reduced to a minimum.

Request for a quote

PATRY

France

RAIL AND ON-RAIL HANDLING SPECIALIST FIXING RAIL ACCESSORIES The various fixing rail accessories are : standard and adjustable clips, sleeper screws, anchorage bolts and fishplates. The clips are used to fix on steel or on concrete. They can be adjustable, to bolt or to weld. The sleeper screws and anchorage bolts allow the fixing of the rail on plates of all types. And the fishplates allow the connection of two rails Standard clips for all the rail section We advise to fasten clips opposite side every 600 mm Tarred, possibility of galvanization Clips fitting dimensions : To know some more Fastening adjustable systems for rails with or without pad Crane rails fastening does present specific problems due to placing conditions, sometimes it is recommended to fix rails. with clips with elastomer insert and possibly elastomer pad to be placed under the rail. For the selection of the system the following information are required : supporting base type of rail pad presence lateral and vertical wheel load width and height available lateral adjustment required Welding clips Bolting clips For more information, contact us please Pads Valex Valex elastomer pads have been specifically developed for elastic laying of crane rails. The Valex elastomer pad, when used jointly with the clips of the Valex series, reduces significantly stress and wear of the rail and of the mechanical components of the crane. It helps to achieve an even distribution of the load of the wheels on the supporting stucture. The use of the elastomer pad is suggested above all in the following situations : the rails are subject to heavy working conditions ; the rails are subject to high vertical and, or lateral wheels stress ; the rails are operating in extreme weather conditions ; noise and vibrations shall be reduced to the minimum. Sleeper screws Anchorage bolts Wedges for wagon immobilization Stop shoe for wheel Ø inferior to 250 mm different types available. Stop block nickel chrome steel for SNCF rail type for wheel diameter superior to 250 mm. Wedge for wagon immobilization with red flag For parked wagon Automatic ejection. Articulated lever can be placed on the left or on the right. Frame in steel sheet, internal in hard wood. Temporary link wagon

Request for a quote

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

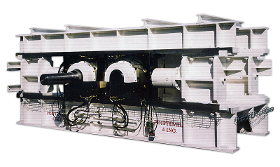

The Cylinder mill, commonly known as the Roller Press works by crushing the material between two cylinders kept under pressure by a hydraulic system (2 to 10 T/linear cm). This mill uses a patented process of pulsating pressure that reduces the level of vibration and contributes in reducing energy requirements and prolonging the service life of wearing parts. It is able to treat high production capacities (up to 500 T/h) and produce fine particle sizes (10 to 1000 microns). Cylinder mills allow for energy savings of up to 30% compared with mills that use traditional crushing methods. The cylinders are equipped with an antiabrasive coating which combined with their slow processing speed provide the grinding solution with the longest service life on the market.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Reduce vibration - Import exportNumber of results

4 ProductsCountries

Company type