- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- presses

Results for

Presses - Import export

ARSILAC

France

TECHNICAL SPECIFICATIONS - Reference : 006833 - PE 80 pneumatic press - 1 door - Tank capacity: 80 HL - AISI 304 stainless steel tank - Open on half conference - Washing ramp - 5.5 Kw compressor: flow rate 140 m3/h - Rectangular door with progressive opening - Food-grade polyurethane membrane - Stainless steel juice drip tray - Integrated control panel - Electrical power: 5.5 kW (in addition to the compressor) - Net weight: 2800 kg DIMENSIONS - Length : 5500 mm - Width : 2300 mm - Height: 2300 mm

Request for a quote

DELTAFLUID

France

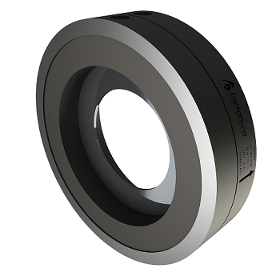

The annular chamber (carrier rings) is proposed for orifice plates, for venturis and for nozzles. It has several advantages: it favors the circulation of the fluid over the complete circumference of the pipework and offers a more stable and precise averaged pressure; in the case of the orifice plate, it also allows to change only the plate in case of maintenance or change of process compared to a monoblock where the complete system must be changed. This type of mounting is particularly recommended for pipe diameters smaller than DN50.

Request for a quote

DELTAFLUID

France

For steam applications, condensate pots are essential. They are used to condense the fluid upstream of the differential pressure transmitter. Installed at the same height, they allow accurate measurement by maintaining a constant condensate height in the impulse lines above the differential pressure transmitter. The condensation pot can also be used to protect the transmitter in the case of a flow measurement of a corrosive / aggressive fluid. In this case we speak of separation pots. For more information, see the Frequently Asked Questions tab on this page.

Request for a quote

DELTAFLUID

France

A flow straightener greatly reduces disturbances in a flow while a conditioner reduces disturbances and also allows a good redistribution of the speed profile, at each point of the section of the pipe. Thus, these devices make it possible to reduce the upstream straight lengths and to improve the measurement accuracy in the case of a flow measurement. They are therefore to be positioned between a pipe fitting (elbow, reduction, etc.) and a flow measurement element while respecting the distances specified in the standard.

Request for a quote

DELTAFLUID

France

Different types of pressure transmitters exist: differential pressure transmitter for measuring a pressure difference ΔP but also a relative or absolute pressure transmitter. For more specific applications, it will be necessary to use: a differential pressure transmitter to correct variations of pressure and temperature of a gas two transmitters for the same differential pressure flow element to increase the measuring range For more details on these cases, please see the Frequently Asked Questions tab on this page.

Request for a quote

DELTAFLUID

France

According to ISO 5167, flowmeters with orifice plates and nozzles (long radius) can benefit from D - D/2 mounting. This corresponds to a positioning of the upstream tap at a distance of 1D (D, internal diameter of the pipework) from the upstream of the orifice plate and the downstream tap at a distance of 1/2D from the downstream of the plate. This type of assembly has the advantage of not requiring orifice flanges (more expensive than standard flanges): you simply prepare bosses on the piping upstream and downstream of the measurement to position the pressure taps. It is widely used for large pipe diameters.

Request for a quote

DELTAFLUID

France

The 1''/1'' flowmeter is also called a flowmeter with flange pressure taps. The high pressure upstream measurement is 1 inch from the upstream edge of the plate and, symmetrically, the low pressure measurement is 1 inch from the downstream edge of the plate. This is often a pre-assembled complete set with orifice plate mounted between orifice flanges. Orifice flanges are standardized and manufactured to ASME B16.36. The orifice plate is manufactured in accordance with ISO 5167 or ASME MFC-3M.

Request for a quote

DELTAFLUID

France

The monoblock diaphragm and the ISA1932 monoblock nozzle are made from a solid round. The pressure taps are directly machined in the monoblock. They can be simply machined (pressure tapping holes) or supplied with nipples to connect directly to your installation. This type of diaphragm or nozzle has the advantage of being simple to install: simply mount it between single flanges or weld directly on the pipe for a version to be welded. All types of edges (sharp-edge, conical, quarter-circle, eccentric, segmental and multi-hole) can be made in a single-piece version. Flanged or corner pressure taps can be made in monoblock version.

Request for a quote

REP INTERNATIONAL

France

Machine features Clamping force 4,000 kN. Platen size 750 x 800 x 80 mm. Injection volume 2,000 cm³ or 5,000 cm³. The H610 allows Automated productions. Injection molding (more or less simple parts). A small footprint and height. An optimized cycle time. etc.

Request for a quote

REP INTERNATIONAL

France

The TYC2RT compression press allows the production of rubber mouldings with compression moulding or vacuum compression. The twoplate in/out with 45° inclination of the upper plate is suitable for various options. They are particularly suitable for moulding Orings, pharmaceutical stoppers, syringe plungers, and many other rubber parts. They are available in 2RT or 3RT series depending on the number of plates in the mould. Equipped with a 4post clamping system with high precision parallelism, their adjustable opening stroke allows different mould heights. The vacuum bell system reduces the curing time, thus increasing productivity.

Request for a quote

REP INTERNATIONAL

France

Machine features Top Closing. Specific pressure 600 kg/cm². Safety light curtain, double hand control. Available in single and doubledeck versions.

Request for a quote

REP INTERNATIONAL

France

Machine features Specific pressure 500 kg/cm². Dimensions of the heating platens 1500 x 1500 mm. Minimum mould closing speed 0.03 mm/sec.

Request for a quote

REP INTERNATIONAL

France

Type V410 Core 1,600kN G10 is the 10th generation of REP injection molding presses with two versions available, on the one hand the Lean range G10 Core and on the other hand the Performance range G10 Extended. The G10 Core is a machine line, which has been matched for less demanding processes. It features all major costoptimized functionalities and the expertise of REP.

Request for a quote

REP INTERNATIONAL

France

REP studies your solution! REP answers questions that cannot be resolved using conventional techniques. An "advanced" competence accompanied by the guarantees of the REP GROUP! A team of engineers is at your disposal for the study and realization of presses for special applications. A REP solution for every problem! We are able to meet your most complex requirements,

Request for a quote

REP INTERNATIONAL

France

Machine features : - Closing force: 2,000 kN Application examples: connector technology, pharmaceutical closures.

Request for a quote

REP INTERNATIONAL

France

Rotocure Conveyor, compression machine from our partner Tung Yu. Rotocure is a continuous curing conveyor used to produce rubber sheets of specific dimensions and shapes.

Request for a quote

REP INTERNATIONAL

France

TYC 22 Press The French company DubourgelGrange is renowned for the quality of its sanitary product range. The factory has fully automated "REP Tung Yu" machinery equipped with handling units and robots (loading and unloading), which operate in 3 shifts for the major part 7 days a week. These machines are used to produce highend toilet covers and seats made in thermoset resin (ureaformaldehyde).

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LBI

France

We manufacture rough or fully machined screw nut in high tensile brass, tin bronze

Request for a quote

LBI

France

We manufacture rough or fully machined bush for transverse shaft in tin bronze

Request for a quote

DOREY

France

CLICKING PRESS WITH MOTORISED ROTATING ARM The new series of F-R punching machines with motorised rotary arm is available both in EC as well as not EC versions at truly competitive prices, with the ad- vantage of less taxing usage for operator, and consequential positive effects for company production. The version for countries subjected to EU standards is supplied with a series of external protection devices, photo electrical protection barriers and an electrical system including various safety devices and lateral tables. For the not EC version, external protection devices with or without photo electrical barriers are supplied upon request, in this case two practical lateral tables are supplied. Light bulb and stroke counter (additional or programmable type) are available upon request for both version.

Request for a quote

DOREY

France

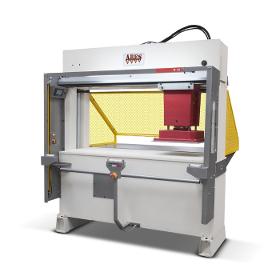

The clicking press ARES combine the best that oleodinamic and electronics can offer in the field of clicking presses. The main features which make them clearly in quality are the following: STURDINESS: the triangular structure of the base with double ribbing and the column of the arm uprated remove bending and ensure great efficency and precision in cutting CONSTRUCTIVE TECHNICS: the lack of rubber packings guarantees an unlimited life to the cylinder elements. The electro-distributor is controlled by a programmed card relized with the most electronic elements with integrated circuits and allows a rapid and silent work

Request for a quote

DOREY

France

Elettric Travelling Head cutting press 25 -30 Ton Most technologically advanced model available on the market of its kind – Fully electric without oil gaskets, pump, motor, flywheel etc – Reduced periodic maintenance that facilitates after sales assistance, remote control and remote assistance – Green production system that respects the environment with low co2 emission -Totally innovative with electric consumption less than 75% lower than a traditional hydraulic die cutter – Sound emission during the operating phase equal to 0 decibels and limited only in the fraction of a second during the cutting phase -Versions available with industry 4.0 preparation

Request for a quote

DOREY

France

Double automatic end of stroke adjustment in order to use different height knives without any setting-up, or electrical end of stroke. Timed adjustable cutting plate upstroke. Adjustable travelling head return. Photoelectric cell protection for traverse and cutting. With cont rol buttons for free access to the work table.

Request for a quote

DOREY

France

Receding head travel controlled by the servomotor, balancing system and 4 columns provide high rigidity and precision of the assembly for a parallel cutting and a power spread equality over the entire surface of the table. LCD touch screen control. Optionally the machine can receive mechanical stops for kiss cutting on steel plate or through cut with material coming from rolls or sheets in semi automatic or automatic mode.

Request for a quote

CHOQUENET SAS

France

The environmental protection has become essential. The water quality is a rare and expensive commodity and its production involves a problem more and more present with the industrial or urban slurries which need to be eliminated at a lower cost and if possible to be recovered. The filter-press has an important place in numerous industries whenever slurries can be concentrated : it can be used either in process or at the end of treatment. In any case the filter-press enables an optimal separation of liquid and solid and the last technical developments which has made it 100 % automatic made it also 100 % topical. The filter-presse is a machine used to filter under pressure the liquids loaded with solid matter in suspension. The filter-press is composed of 3 main parts : the frame, the filter part and the hydraulic power unit..

Request for a quote

CHOQUENET SAS

France

The environmental protection has become essential. The water quality is a rare and expensive commodity and its production involves a problem more and more present with the industrial or urban slurries which need to be eliminated at a lower cost and if possible to be recovered. The filter-press has an important place in numerous industries whenever slurries can be concentrated : it can be used either in process or at the end of treatment. In any case the filter-press enables an optimal separation of liquid and solid and the last technical developments which has made it 100 % automatic made it also 100 % topical. The filter-presse is a machine used to filter under pressure the liquids loaded with solid matter in suspension. The filter-press is composed of 3 main parts : the frame, the filter part and the hydraulic power unit..

Request for a quote

DOREY

France

Four columns press with mechanical balancing system SYSCO exclusive Cutting power from 30 to 400 Tons Cutting area from 900 x 600 to 2500 x 1200 mm Cutting stroke from 110 to 250 mm 4 manual or motorised mechanical stops accuracy +/ 0.01 mm Trough cutting or kiss cutting on Picard steel plate 60 HRC accuracy +/ 0.01 mm Slow down speed of the bridge 10 mm before touching the material Quick change of dies Touch screen control in different languages Use of electrical, hydraulic and pneumatic standardized Safety guards protection and / or photocells Class 4 Meets C.E. standards

Request for a quote

CHOQUENET SAS

France

Maintenance and expertise With a team of more than 15 people, we put all our resources at your disposal to ensure a global and complete follow-up of your machines. Our experts intervene all over the world in order to guarantee you the best performance of our equipment. We have several mechanics and hydraulic engineers who will help you in the management of corrective maintenance Our offer extends over several fields, from the simple replacement of worn parts to the advanced optimization of the performance of our machines with the support of our automation specialists and engineers. As preventive maintenance has become a major issue in recent years, we also offer maintenance and monitoring contracts for installations, thus ensuring the reliability of your installations with complete peace of mind.

Request for a quote

CHOQUENET SAS

France

CHOQUENET provides its customers with mobile units to confirm feasibility on site The company provides several mobile filtration units of different sizes (from the laboratory unit of 250 cm² filtering surface to the semi-industrial installation of 9 m²). These units make it possible to test many parameters in an easy way. Rental can be on a one-off basis (for a week or less) or on a more permanent basis (up to several months for specific production needs).

Request for a quoteResults for

Presses - Import exportNumber of results

35 ProductsCountries

Company type