- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- conveyors

Results for

Conveyors - Import export

FEMIA INDUSTRIE

France

Installed at the line infeed of granular products such as peas/flageolet beans, it extracts small size waste and sticky waste as well as large waste. Machine primarily comprised of a drum of which the perforations of the final section are adapted to the product processed. Continuous cleaning of the machine thanks to its system of brushes and scrapers. Products to be processed exit from the 3rd section of the drum. Collection and discharge of waste thanks to a conveyor inside the drum (except for small size waste at the beginning of the machine).

Request for a quote

FEMIA INDUSTRIE

France

Provides receiving, storage and feeding of the product downstream. The dimensions can be adapted according to the capacity of the line and the means of unloading raw materials used. A conveyor belt with high sides which provides the storage and transport of products.

Request for a quote

FEMIA INDUSTRIE

France

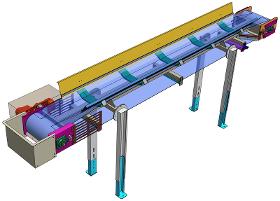

Provides the product transfer from a piece of equipment located upstream to a piece of equipment located downstream. Can be adapted according to your needs and capacities.

Request for a quote

FEMIA INDUSTRIE

France

The conveyor provides the product transfer to the machine located downstream. The distributor evenly and continuously transfers your products to several machines downstream. Several outlets and fully adjustable deflector flaps guarantee ideal distribution of your products between the various outlets. Can be adapted and customised according to your needs and capacities (length, width, number of outputs).

Request for a quote

FEMIA INDUSTRIE

France

Installed at the inletof the line for granular products such as peas/flageolets, it removes small waste, sticky waste as well as large waste. Machine mainly consisting of a drum whose perforations in the final section are adapted to the product being treated. Continuous cleaning of the machine thanks to its system of brushes and scrapers. Exit of the products to be treated under the 3rd section of the drum. Recovery and evacuation of waste thanks to a belt conveyor placed inside the drum (except for small waste at the beginning of the machine).

Request for a quote

FEMIA INDUSTRIE

France

Saws the husked ears of corn into several pieces (1 to 3). Capacity (automatic feeding version) of 110 ears/minute with the ACC feed system of the cutter. Capacity (manual feeding version) of 60 ears/minutes with two operators. Machine primarily comprised of an automatic feed (automatic feeding version only), a roller conveyor and a cutting head with circular saws. For the two versions, an operator manages the orientation of the ears on the conveyor belt Roller conveyor for visual control and feeding the saw. Adjustment of the cutting of the ends of the ears and of the pieces for a desired length.

Request for a quote

FEMIA INDUSTRIE

France

According to your needs, transfers and/or elevates products to a machine located downstream. Can be adapted according to your needs and capacities. Increased reliability thanks to its stainless steel structure. Better preservation of the product thanks to its plates with or without plastic flights.

Request for a quote

FEMIA INDUSTRIE

France

Transfers and feeds the product in a piece of equipment located downstream. Adapted according to your needs and your production.

Request for a quote

FEMIA INDUSTRIE

France

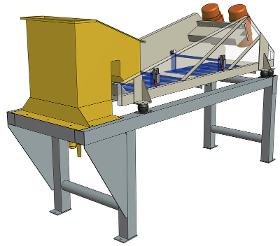

Cross cuts long shaped products (<20cm) into 26, 32, 39 or 52 mm pieces.Machine comprised primarily of an aligning vibrator and of a cutting head comprised of two straight blade rollers. Excellent straight cutting regularity thanks to a vibrating system that aligns the processed products. Tilting system of the cutting head for adjustments and maintenance.

Request for a quote

FEMIA INDUSTRIE

France

Chops maize waste in particular to facilitate future valuation. Machine mainly consisting of a heavy drum (high inertia) and multiple hammers fixed regularly on the cylindrical part of the drum. Several models available depending on the capacity of the product to be shredded. Carrying structure to be added under the equipment to facilitate the exit of the crushed product. Adapted to the architecture of the line and the constraints of the building. Translated with www.DeepL.com/Translator (free version)

Request for a quote

FEMIA INDUSTRIE

France

Designed for your operators for a complete visual inspection and manual removal of waste mixed in with products.

Request for a quote

FEMIA INDUSTRIE

France

Today, waste management has become a genuine challenge in sustainable development and yield on fruit and vegetable processing lines. Femia provides solutions aimed at extracting only the waste, without affecting the processing of good products. According to a model based on green and circular economy, they are then brought together, recovered and recycled.We design, along with you, a logic for customised waste recovery, according to your material recycling objectives (animal feed, farm use with or without composting), energy (methanisation) or incineration with energy recovery. We integrate the recovery approach right from the design phase for your production lines in order to allow your conveyors progressive and facilitated recovery of wastes all throughout theproduction lines.

Request for a quote

FEMIA INDUSTRIE

France

With the production of deep frozen products, calibration and even sorting can be required aiming for global optimisation of the process and of the storage of the products as well as of their quality. At this step in your production, FEMIA offers various process functions that can be used after deep freezing, such as cleaning, calibration and sorting. Our solutions allow you to effectively sort products according to their grade (peas, cauliflower, broccoli or cut vegetables in particular) in order to limit intermediate storage and the management thereof before deep freezing. Thanks to the sorting and calibration post deep freeze, you can store your deep frozen products in bulk in large containers and pack them as your orders come in, in order to smooth out your production flows.

Request for a quote

FEMIA INDUSTRIE

France

Provides the product transfer from a piece of equipment located upstream to a piece of equipment located downstream. Can be adapted according to your needs and capacities.

Request for a quote

FEMIA INDUSTRIE

France

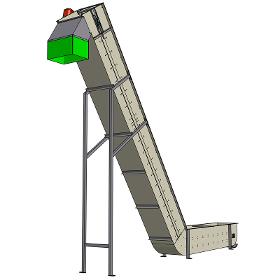

Transfers and lifts the clean product from one piece of equipment to a piece of equipment at a higher level. Several scraper widths are available according to the capacity of the product to be transferred. Adapted to low mass products Adapted to the architecture of the line and to the constraints of the building.

Request for a quote

FEMIA INDUSTRIE

France

Transfers and lifts the product from one piece of equipment to a piece of equipment at a higher level. Adapted to granular products (e.g. peas). Several bucket widths and depths are available according to the capacity of the product to be transferred. Adapted to the architecture of the line and to the constraints of the building.

Request for a quote

FEMIA INDUSTRIE

France

Transfers varied small size products in a flow of water propelled by a pump Ideal for long distance transfers. Characteristics of the hydraulic circuit (length, elevation pressure head, etc.) depending on the required product flow rates.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FEMIA INDUSTRIE

France

Conveying is an important element in the performance of your production lines with the dual challenge of limiting product degradation and losses as well as the proper feed on to the downstream machine, an essential point for optimum performance.Belt conveyor, vibrating conveyor, flighted belt elevators, scraper or bucket elevators, hydraulic transporters, we can adapt many conveying solutions to your lines. Our conveying systems must be selected according to the architecture of the preparation line and products processed in order to represent the solution that will provide you with the best performance and meet the particular challenges of your production.In addition to the diversity of the machines that we can apply to your line, our know how resides in our ability to adapt to your needs. We propose a solution that aims to optimise the layout for a minimum amount of space occupied while still including the maintenance constraints.

Request for a quote

FEMIA INDUSTRIE

France

Suitable for multiple products (except for leafy vegetables).Decrease in the product temperature by several tens of degrees according to the ambient temperature. Low water consumption, respect for the product and the environment. Possibility of filtering the air intake to the cooler.

Request for a quote

FEMIA INDUSTRIE

France

Precise control of the parameters and homogeneous processing of the product by maintaining the temperature through the entire thickness of the product layer for the time required for blanching (and even pre cooking) the processed products. High material yield by preserving as best as possible the organoleptic qualities of the processed products. Minimum water consumption according to the operating mode selected. Optimisation of the dimensions of the equipment according to the range of products to be processed and of the space constraints of the installation zone.

Request for a quote

FEMIA INDUSTRIE

France

Pulls off the husks of unprocessed ears of corn.Machine primarily comprised of a roller table, a vibrating feeder and of a variable speed conveyor with its hopper in the upper portion. The roller table is comprised of 4, 8, 12 or 16 “Lanes” keeping in mind that a “Lane” comprises 2 axes with rollers. Range of various husker rollers according to the variety of corn processed Regular feed thanks to a variable speed conveyor belt and a vibrator that aligns the ears before the roller table. Recovery of the husk and silk waste under the roller table.

Request for a quote

FEMIA INDUSTRIE

France

Special for spinach.Machine comprised pre washing and washing tanks, pumps that allow for the creation of turbulent flows, some insect trap and propeller to make the leaves plunging in the turbulent bath. Recovery of the water in a settling tray at the outlet of the washer and filtering of the water with a wire rotating drum and its scraper in order to separate the waste. Circulation of water in a closed loop for low water consumption.

Request for a quote

FEMIA INDUSTRIE

France

Extracts the waste that is denser (stones, clumps of soil, various objects etc.) than the processed product. Machine primarily comprised of a destoning tank, a pump that allows for the sustentation of the processed products and a vibrating draining separator. Recovery in a settling tray under the separator and filtering of the water with a wire screen. The upper screens of the vibrating separator can be removed and are perforated according to the product processed. Continuous removal of heavy waste in a chamber with 2 controlled valves and its control box.

Request for a quote

FEMIA INDUSTRIE

France

eparates the elements that are denser than the processed product. Suitable for most vegetables.Machine comprised primarily of a tapered tank with a blade system that allows for the creation of a vortex in the tank, a pump that allows for the sustentation of the processed products and a system for water recovery. Water recovery and filtration via a modular plate belt or a vibrating drainer and a settling tray. Circulation of water in a closed loop for low water consumption. Removal of waste thanks to a stone lifter or a chamber with 2 controlled valves and its control box.

Request for a quote

FEMIA INDUSTRIE

France

This step of washing is as essential with regards to quality and the health stakes that processing food products represents. Destoning and washing use water to separate and wash the products of any foreign body that could still be entwined therein. Destoning is done upstream of washing and, due to the hydraulic process, carries out a pre washing with a water circuit different from that of washing in order to improve the performance of the latter. FEMIA is well known worldwide for its efficient and compact solutions for destoning and washing. Destoning through extraction or water flow, dedicated or universal washers, we have developed many solutions for destoning and washing floating and sinking products. We offer options according to needs (insect traps, for example). Combining performance and robustness, FEMIA equipment is recognised in the market for its quality and longevity.Always very attentive to your performance and our impact on the environment,

Request for a quote

FEMIA INDUSTRIE

France

Separates large waste from granular products, such as peas, flageolet beans and sweet corn and provides continuous and even distribution of the processed products to a downstream machine. Vibrator comprised primarily of a vibrating pan with removable and perforated screens according to the dimensional characteristics of the products processed. An additional option for draining/water recovery using perforations on the bottom of the pan and a hopper under the pan.

Request for a quote

FEMIA INDUSTRIE

France

Separates unsnipped green beans from the flow of green beans. Machine comprised primarily of a drum with louvered slots, a rotating blade system and a conveyor inside the drum to collect the unsnipped green beans. At the outlet removal of the unsnipped green beans on the dedicated belt and snipped green beans on another belt. A continuous cleaning of the machine.

Request for a quote

FEMIA INDUSTRIE

France

Separates the free beans from the mechanically harvested green bean clusters. Machine primarily comprised of a drum fitted with hooks of special shape. Mobile machine mounted on rollers so that the position of the drum can be adjusted in relation to the fall of products above the drum.

Request for a quote

FEMIA INDUSTRIE

France

Removes and sorts small pieces of long shaped products of the green bean, carrot, salsify, etc. type. Machine comprised primarily of a drum fitted with plastic pockets and a conveyor inside the drum to collect the small pieces from the flow of products. Different pocket diameters are available according to your needs. The machine is continuously cleaned thanks to its system of brushes and CIP(clean in place ).

Request for a quoteResults for

Conveyors - Import exportNumber of results

56 ProductsCountries

Company type