- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- milling design

Results for

Milling design - Import export

SPM - SOCIÉTÉ PYRÉNÉENNE DE MÉTALLURGIE

France

DRILLSTAR Taper mill is used to repair collapsed casings or tubings, and to shave off cement or corroded parts in casings. The taper mill hardfacing is designed to clean the casing without cutting it, and to penetrate very gradually. The upper part of the taper mill is long enough to allow the addition of stabilizing blades while still remaining easy to fish. DRILLSTAR Taper mill is available in two types, long or short. Blades, whether spiralled or straight, are fully customizable.

Request for a quote

SPM - SOCIÉTÉ PYRÉNÉENNE DE MÉTALLURGIE

France

Section mills are designed for cutting and milling a complete section of casing. All models 4 1/2 in. OD and above are equipped with 2 sets of 3 knives: 1 long set and 1 short set, designed for first cutting and then milling the casing. Knives can be hardfaced with your choice of TOPLOY carbide grains or TOPMILL/SWORDFISH tungsten carbide inserts. For most jobs, TOPMILL inserts are strongly recommended to improve milling performance. This tool can be equipped with Flo-tel, which produces a sudden drop in mud pressure when the pipe is cut out, indicating the right time to start applying milling weight.

Request for a quote

MECANUMERIC

France

The rigour and the accuracy for the industrial works, the polyvalence and the simplicity for a maximum of profitability. Designed for the accurate and intensive works, they allow a wide field of applications : metal engraving, fine millings, design, prototyping Refer to the exemples of applications : Moulds and models Health case or box Side windows Aircraft interior furnishing Jewels engraving Masks Household appliances Lights Furniture Aluminium frames The strengths • XYZ stroke 310 x 430 x 120 mm (DMC300) - "Y" reduced to 250 mm in case of automatic tool changer. • XYZ stroke 600 x 610 x 120 mm (DMC600) - "Y" reduced to 420 mm in case of automatic tool changer. • Rigid structure made of steel / Aluminium foundry. • Double guiding by prismatic rails in grinded steel with re-circulating ball bearings. • Ball screw with pre-stressed sockets. • Cinematics fixed table / mobile gantry. • Available in « servo-brushless » motorization. • Economical version with stepper...

Request for a quote

MECANUMERIC

France

MECAPLUS-HP “AGILE” MACHINING High precision and performance solution HIGH PRODUCTIVITY 3 axes milling equipment : “AGILE” MACHINING • Designed and realized for an intensive use. • Heavy, fast, powerful, precise and efficient equipment, easy to operate for the machining of rigid sheet materials of strong thickness, in the fields of plastic processing, modelling, aeronautics, aluminium processing… or for the machining of molds and 3D models. • Particularly adapted for the machining of aluminium, plastic materials of strong thickness and composite materials with high mechanical properties. • Many customization possibilities. • Innovative and efficient vacuum tables with turbine technology or vacuum pumps. • Numerical controls SIEMENS or HEIDENHAIN type. • Quality kinematics integrating industrial components supplied by the world leaders in their field, mounted on welded stabilized steel frames.

Request for a quote

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

The HammerKnife Universal Mill is the combination between a Hammer Mill and an Universal Mill. As the FORPLEX FNG Mill it can be equipped with different grinding tools (hammer plate ou blade plate) which are adjustable in relation to the product to be ground. The FK Mill has the same advantages as the Universal Pin Mill FNG easy to use, easy to clean, easy to maintain, but also simplicity of changing the grinding tools or grids. Perfect for technical applications such as the grinding of natural ingredients (knife rotor designed for the crushing of plants), the FK mill was designed to meet the standards of the foodstuffs industry, fine chemicals industry, pharmaceuticals industry, nuclear industry or even for cosmetics. It can meet FDA, GMP or ANIA standards and criteria. With the robustness and strength of hammer crusher

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

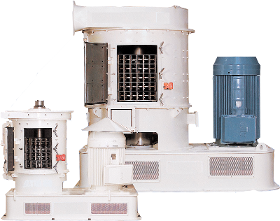

The ATTRIMILL is an attrition mill (or kinetic mill) principally used for plastics or fibrous products. It combines three physical principles that generate efficient ultrafine grinding. The autocomminution of the particles generated by the upward air spiral, The comminution of the particles created by pressure changes generated by variations in the air flux /matter projections against the blades and the stator, The shearing of the particles between the blades and stator grooves. The internal design of the mill depends upon the type of product and the required fineness. The range is divided into several versions according to the sector of activity and products to be treated Stainless steel for foodstuffs, pharmaceuticals or chemicals, ceramic lining for abrasive products, resistance to an accidental explosion (PSR 10 bars) etc... We have a full range from the ATM8 (several kg/h) up to the ATM600 (up to 25t/h).

Request for a quoteResults for

Milling design - Import exportNumber of results

7 ProductsCountries

Company type