- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- timing belts

Results for

Timing belts - Import export

ERO JOINT .TANALS

France

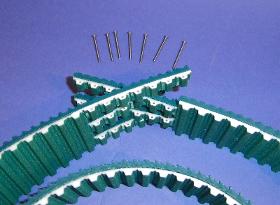

The mechanical fastening system ERO Joint® is available on pitches T10, AT10, T20, AT20, 8M, 14M for all widths over 16mm with reinforcement Steel, Kevlar or Stainless steel. (The recommended minimum diameter for pulleys is 50mm). The ERO Joint® splice is compatible with all type of coatings (Supergrip, Linatex®, PU, Sylomer®, …) and all types of guiding. ADVANTAGES Advantages are a fast and easy installation and assembly. With the pin mechanical fastening system ERO Joint®, you will optimize your production downtime by reducing the repair time. The assembly can be realized by screwing or with a tool. This tool enables the pre-tension of belt and makes pins threading easier. ERO Joint ® Ultimate version In Ultimate version, the mechanical belt fastener ERO Joint® transmits more than 50% of the power of a Flexbelt (true endless belt): Between pulleys, there is always a ½ continuous tight side to assure the mechanical resistance and the rigidity of the belt.

Request for a quote

ERO JOINT .TANALS

France

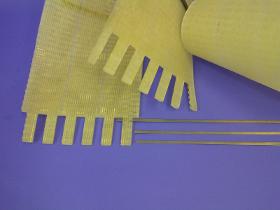

Advantages are a fast and easy installation and assembly. With this new solution of mechanical fastening system, you will save time and optimize your production downtime by reducing the repair time. The recommended minimum diameter for pulleys is 50mm. The mechanical joint system ERO Joint® WT is compatible with conveyor belts scrapers. Mechanical fastening systems ERO Joint® WT are lasting solutions. The ERO Joint® WT splice shape may be adapted in order to increase the mechanical resistance. ERO Joint® WT is the only one solution of mechanical belt fasteners in wide timing belts. The ERO Joint® WT wide timing belts are spliced in our production using a patented process and fitted with the length requested.

Request for a quote

ERO JOINT .TANALS

France

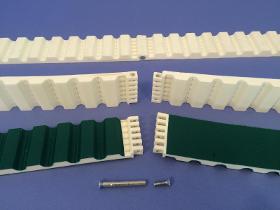

ADVANTAGES Advantages are a fast and easy installation and assembly. With the hinge pin mechanical fastening system ERO Joint® HP, you will optimize your production downtime by reducing the repair time. Mechanical strength and lifetime are higher than any other mechanical fastening systems. Mechanical resistance and elongation are equivalent to welded belts. TENSIONING TOOL FOR ERO JOINT® HP Alternatives Spiral seams The mechanical spiral seams system is also very easy to assemble as ERO Joint® HP but its mechanical resistance is poor. Pin Joint The mechanical Pin Joint system is more difficult to assemble than ERO Joint® HP. The mechanical resistance is also lesser than ERO Joint® HP.

Request for a quote

LANDA SAS

France

Discover our range of belts for agricultural equipment: V-belts, variator belts, poly-V belts, hexagonal belts, timing belts and flat belts. To provide you with the most comprehensive range and impeccable quality, we work with the leading brands of belts: Gates, Optibelt. Our range includes almost 1,600 references, 975 of which are in stock. Landa offers a range of agricultural parts for forage harvesters, combine harvesters, balers, mower conditioners, windrowers and tedders. We develop wear parts for harvesting machines that are equivalent to original manufacturer parts, in partnership with industrial companies specialising in the fields of metallurgy (assembly, machining, forming).

Request for a quote

NORELEM FRANCE

France

The tension meter is used to perform a pretension test on commercially available belt systems quickly and easily by means of frequency measurement. Fully electronic and equipped with stateoftheart microprocessor technology, the meter enables precise adjustment of all V, toothed and flat belts that have to be tensioned in the range from 10 to 600 Hz. The measurement must never be performed while the drive is running The meter is not permitted or certified for use in potentially explosive areas.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NORELEM FRANCE

France

Endless toothed belt with trapezoidal profile to DIN 7721 T1 with metric pitch. Ideal for drives with high belt flexibility. Permits smallest pulley diameters. The toothed belts are intended for drives where precision is a requirement, safety is important and the effects of chemicals are a concern. maintenancefree highpower transmission minimal belt extension accurate positioning and angles very good chemical resistance, especially to oils, greases and fuels extremely high abrasion resistance transmits power up to 30 kW reliable speed up to 10,000 rpm

Request for a quote

NORELEM FRANCE

France

Standard ATprofile with metric pitch (trapezoidal toothing). For manufacturing your own toothed wheels

Request for a quote

NORELEM FRANCE

France

Standard HTD profile with metric pitch (rounded toothing). At least one toothed belt pulley must have a rim flange. Conical hole for taper clamping bushes. The taper clamping bushes must be ordered separately and are available for various shaft diameters. Pulleys with a taper hole are statically balanced as per ISO 1940 grade G16.

Request for a quote

NORELEM FRANCE

France

Steel. Toothed pulleys without aluminium rim flanges. Version Steel phosphated. Aluminium bright. Note Standard HTD profile with metric pitch (halfround toothing). At least one belt pulley must have a rim flange. The toothed belt pulleys have a centre bore or a pilot hole (this can vary due to manufacturing methods). For this reason, the dimension D2 max. given in the table is the maximum diameter of the bore with which the toothed belt pulleys are supplied. This pilot/centre bore can be amended by the customer to produce a reamed bore, reamed bore with keyway or a tapped hole. Alternatively, customers can also use bushes to reduce the bore diameter. The pulleys may be recessed on the sides.

Request for a quote

NORELEM FRANCE

France

Aluminium. Rim flanges, steel. Version Aluminium bright. Steel electro zincplated. Note Standard T profile acc. to DIN 7721 T2 with metric pitch (trapezoidal toothing). At least one belt pulley must have a rim flange. The toothed belt pulleys have a centre bore or a pilot hole (this can vary due to manufacturing methods). For this reason, the dimension D2 max. given in the table is the maximum diameter of the bore with which the toothed belt pulleys are supplied. This pilot/centre bore can be amended by the customer to produce a reamed bore, reamed bore with keyway or a tapped hole. Alternatively, customers can also use bushes to reduce the bore diameter.

Request for a quoteResults for

Timing belts - Import exportNumber of results

11 ProductsCountries

Company type