- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- steel-forming

Results for

Steel-forming - Import export

SAS T2I

France

Ø 13 - 17 - 19 or 25 mm Galvanized or phosphated Material: Steel or stainless steel

Request for a quote

NORELEM FRANCE

France

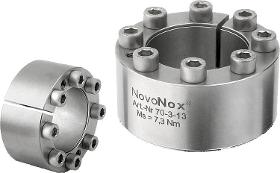

Shrink disc to connect a hollow hub to a shaft. They are mounted on the OD of the hub and generate pressure on the hub wall by reducing the ID with wedgeformed rings, creating a press fit between the hub and shaft. They are suitable for static, dynamic and shock loads. for extremely high torques no axial shaft/hub offset when assembling selfcentring The version 23380014072 has high tensile ISO 4762 screws. Assembly Remove existing transportation locks. Clean and lightly oil shaft, internal and external hub diameters. Do not use MoS2 or grease. Slide shrink disc onto hub. Then slide unit (shrink disc/hub) onto shaft and position correctly. Gently tighten clamping screws one after the other by hand. Then use a torque wrench to tighten the clamping screws crosswise in several increments to the defined tightening torque MS. 1st increment approx. 33% MS 2nd increment approx. 66% MS

Request for a quote

NORELEM FRANCE

France

Coupling stainless steel 1.4057. Screws stainless steel 1.4301. For applications that require a small construction volume and low surface pressure. The keyless locking coupling can be fully recessed in a hub connection. for shaft diameters 6 20 mm suitable for hubs with low wall thickness minimum axial offset possible selfcentring Assembly Lightly oil keyless locking coupling on the tapered faces and contact points of the shaft and hub. Do not use MoS2 or grease. Insert keyless locking coupling in the hub seat and slide onto shaft. Tighten screws crosswise in several increments to the defined tightening torque. Dismantling Remove all screws and screw into the extraction threads of the front flange. Tighten screws crosswise in several steps until the keyless locking coupling loosens. Tolerances Shaft Recommended tolerance h8. Surface quality Rz ≤ 16 µm. Hub Recommended tolerance H8. Surface quality Rz ≤ 16 µm.

Request for a quote

NORELEM FRANCE

France

1.4401 stainless steel, similar to DIN 39. Grip suitable for DIN 950 handwheels.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NORELEM FRANCE

France

Body tempered, black oxidised. Ball hardened, bright. Inserts: Form C, F hardened, black oxidised. Form M with carbide serrations, black oxidised. Form K white. Form E hardened, bright. Form O diamond impregnated surface comparable to 100 grade abrasive grit. Form P polyurethane surface, hardness 60 Shore. Note: Self-aligning pads are used to support and clamp unmachined and machined workpieces. In addition, they serve as stops, supports and thrust pads in fixtures and toolmaking. The ball can be removed from the housing by applying light pressure to the socket head screw. Ball secured against rotation. Advantages: Highly cost-effective as inserts can be exchanged. The built-in O-ring holds the ball in place and keeps dirt and foreign particles out, ensuring uniform movement. Drawing reference: Form C: flattened steel insert, smooth Form E: flattened stainless steel insert, smooth Form F: gripper face Form K: flattened POM insert, smooth

Request for a quote

NORELEM FRANCE

France

Body carbon steel. Ball, ball bearing steel 1.2067. Form D: Ball with POM insert. Form H: Ball with POM insert. Form K: Ball with carbide insert. Form M has a carbide ball. Version: Body tempered and phosphated. Ball hardened. Form M ball nickel plated. Note: Self-aligning pads serve as stops, supports and thrust pads in fixture constructions. Ball secured against rotation. * Valid only if the minimum bore depth is observed. Drawing reference: Form C: with male thread, flattened ball, smooth. Form D: with male thread, flattened ball, with POM insert. Form F: with male thread, flattened ball, diamond grip. Form M: with male thread, flattened ball, with carbide insert. Form G: press fit, flattened ball, smooth. Form H: press fit, flattened ball, with POM insert. Form J: press fit, flattened ball, diamond grip. Form K: press fit, flattened ball, with carbide insert.

Request for a quote

NORELEM FRANCE

France

Material: Housing thick steel plate. Tyres steel-wire reinforced elastic solid rubber. Wheel body welded steel. Version: Housing press formed. Reinforced fork, base plate and centre pin. Double ball bearing with hardened shells in the castor head. Precision ball bearings in the wheels. Note: These castors are particularly impact and shock proof and assure a high service life. Wheel axle bolted.

Request for a quoteResults for

Steel-forming - Import exportNumber of results

9 ProductsCompany type