- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pneumatic systems

Results for

Pneumatic systems - Import export

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

Our metal work services are fully adapted to meet your facilities maintenance and safety needs : replacement and/or modification of walkways installation and/or modification of ventilation ducts manufacture and installation of floors and access doors on production lines welding of reinforcements on to machine frames modification of fabric drive systems, presses, cylinders and rollers modification of pneumatic and hydraulic control systems installation of conveyor lines mechanical protective equipment: grids, gratings, walkways and doors machine guarding: stainless steel, steel, etc. We guarantee a highly flexible and adaptable service, while meeting all of your production requirements and maintaining the configuration of your existing facilities.

Request for a quote

AVM AUTOMATION

France

Pneumatic retractable stop Locking by toggle joint action Adjustable stop screw Operating principle of the retractable stop This retractable stop is drived by a doubleacting pneumatic cylinder. It is retracted by a 90 ° rotation of the finger. When it is engaged to stop the moving element, it is mechanically locked by a toggle joint action. The retractable finger supports an impact force of 2250 N or less, it is generally necessary to provide damping at the point of contact (elastic or hydraulic depending on the application). Detection by 2 inductive Ø8 detectors is optional. Using of the retractable pneumatic stop There are 3 common applications for this retractable stop • Create an intermediate position for a manipulator or a linear pneumatic gantry • Create a conveyor stop • Referencing a product on a workstation For an intermediate position of the pneumatic manipulator, a hydraulic shock absorber must be placed opposite the stop screw.

Request for a quote

AVM AUTOMATION

France

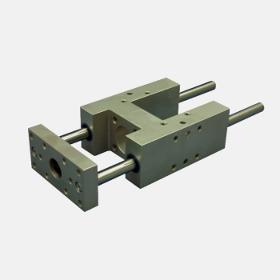

Our H guides can be adapted to many electric actuators of the market (with threaded rod or tapped rod). Also available in anticorroding version (AluStainless Steel)

Request for a quote

AVM AUTOMATION

France

For electric cylinders ISO 15552 size 32 to 100 Selfcentering rod coupling without axial play adapted to positioning Principle of rod coupling with reduced axial play Rod coupling with adjustable axial playThe difference with the ISO 15552 pneumatic cylinder guide units is at the level of the cylinder rod coupling on these guides for electric cylinders, the selfaligning rod coupling has no axial play (or a reduced axial play) depending on the assembly carried out, these units without axial play are therefore suitable for positioning applications. For applications without positioning accuracy or with high radial loads in static, it’s possible to use the guide units for pneumatic cylinders with a guide on plain bearings, since the rod coupling has an axial play (<0,2 mm). Guides for nonISO actuators For electric actuators which are not ISO, we know how to adapt our guide units to most of the rod actuators on the market see Hguide for actuators.

Request for a quote

AVM AUTOMATION

France

Guides, delivered without motor, allows to realize systems with 1, 2 or 3 axes For LinMot® motors P0123, P0137, P0148 Stainless steel version for *SSC motors Presentation of the range of guides for LinMot® motors These guides are intended exclusively for cylindrical linear motors of the LinMot® brand and are broken down into 5 families LB modules for pick and place manipulators LE modules Gantry LR LH guide units comparable to guide units for pneumatic cylinders Guides in stainless steel LX and LW for motors * SSC Special features of the LE and LB modules On LE modules, for vertical applications, it’s possible to have a mechanicalpneumatic brake or a LinMot MagSpring. The LB23 module is equipped with pneumatic balancing (antifall in the event of a power outage but also for high speed by eliminating the impact of gravity).

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

AVM AUTOMATION

France

Pneumatic gripper with 2 or 3 concentric fingers Single acting with rear central air connection High clamping force External clamping and vertical using only Without detection Screwing gripper technology The technology of this gripper allows it to develop a very large clamping force (about 10x the force of a gripper) so as to obtain the necessary tightening torque in the following applications – screwing cosmetic or hygiene bottles, with or without spout – screwing of pots or cans with torque control – screwing of thermostatic subassemblies – screwing push buttons The central rear pneumatic supply and single acting makes it easy to mount on a rotating joint. Screwing bottles with pump spoutThe wide angle opening version is generally used for screwing vials with pump spouts. The 2finger version makes it possible to tighten square or prismatic caps, but also to reduce cycle time by let go the bottle radially by opening the gripper at the height of clamping

Request for a quote

AVM AUTOMATION

France

Pneumatic gripper with 2 concentric fingers Finger selflocking closed gripper (toggle joint action) Elastic absorption at opening Interest of 180 ° angle grippers Grippers with 180° opening angle are generally used to suppress a clearance movement because the open fingers allow the product to pass laterally, for example during a linear transfer or for maintaining a product on a turntable. Selflocking on closing by toggle effect These grippers use toggle technology that allows selflocking of the jaws in the last degree of closure and a large clamping force. They therefore remain locked even in the absence of air pressure. They can only be used for a grip from outside the piece and for parts with an identical grip dimension. The detection cam mounted on the axis of rotation allows the 2 inductive sensors to detect any desired position. The option « opening screw limitation » allows to adjust the opening stroke if the 180 ° are not sought

Request for a quote

AVM AUTOMATION

France

Pneumatic parallel gripper with 2 concentric fingers and long opening stroke. Very long prismatic guide for torsional torque resistance. Exceptional length/stroke ratio Interest of longstroke parallel grippers These pneumatic parallel grippers with long opening stroke can seize parts with very different sizes (example a range of bearings, a range of wheels …). The length of the sliders makes it possible to support fairly long jaws without the risk of buttressing. Exceptional length/stroke ratio and robustness The clamping force and guiding quality are constant throughout the stroke. The slides being mounted in parallel, these grippers have a very good stroke/length ratio. With a hard anodized body, a long prismatic steel guide, these parallel pneumatic grippers are reliable and robust. Mounting interfaces allow them to be integrated into a pneumatic handling assembly.

Request for a quote

AVM AUTOMATION

France

Handling pneumatic gripper with parallel clamping with 3 concentric fingers. The guide is prismatic and mechanism is completely protected Benefits of 3finger parallel tightening Although most handling applications are using parallel grippers with 2 fingers, because even in the case of cylindrical parts, Vshaped jaws allow a good grip. The use of a gripper with 3 fingers is preferred in 2 case – refocusing of the part along 2 axes during tightening – stability of a long cylindrical part clamped by its end In the particular case of screwing, we have a range of 3jaw grippers specifically dedicated to screwing Type 2913 grippers. Reliability and robustness of Type 24 parallel grippers With a hard anodized body and cylinder, prismatic steel guide, fully protected mechanism, these pneumatic parallel grippers are robust and reliable. The positions are detected by magnetic detectors (delivered separately) thanks to 2 Tgrooves on the upper face of the cylinder.

Request for a quote

AVM AUTOMATION

France

Handling pneumatic gripper with parallel clamping with 2 concentric fingers. The guide is prismatic and mechanism is completely protected. Benefits of 2finger parallel tightening The clamping of these parallel grippers is the most polyvalent clamping it allows to take pieces of slightly different sizes with the same jaws, to grab a piece in a limited space at opening, to seize the part by the inside or the outside … For very different sizes of parts, it’s possible to grip them without changing jaws with Type 25 parallel long stroke grippers. Reliability and robustness of Type 24 parallel grippers With a hard anodized body and cylinder, prismatic steel guide, fully protected mechanism, these pneumatic parallel grippers are robust and reliable. The positions are detected by magnetic detectors (delivered separately) thanks to 2 Tgrooves on the upper face of the cylinder. This groove is compatible with many detectors on the market to facilitate maintenance.

Request for a quote

AVM AUTOMATION

France

Motorization by integrated pneumatic cylinder Driving by rack and pinion system Adjustable mechanical stops Hydraulic shock absorbers Inductive sensors The wrist of a manipulator arm These rotary modules are, for example, the wrist of a manipulator arm, the turner of parts on a conveyor or the axis of rotation of an oscillating manipulator. In general, they rotate the gripper that grips the part. These modules are equipped with hydraulic dampers and inductive sensors, the rotation guidance is ensured by 2 ball bearings that allow this module to be used in all directions, even with offcentered payload. Rotary cylinder without angular play at end of stroke The end stops located under the plate allow there to be no shock in the rack and pinion transmission and no angular play at the end of the stroke. The absence of angular play allows use in assembly or precise positioning applications with 2 positions and the absence of impact in rack

Request for a quote

TOTALENERGIES LUBRIFIANTS

France

Extreme pressure grease, formulated for the lubrication of plain bearings of applications, operating at medium and slow speeds, where the grease is required to support exceptional heavy loads in wet conditions. Suitable for applications in civil engineering and industry, where the grease is submitted to water wash-out and pollution. Suitable as EP multi purpose grease, slow moving heavily charged industrial and "off road" applications where water is in frequent contact with the grease. Always avoid contamination of the grease by dust and/or dirt when applying. Preferably use a pneumatic pump system or cartridges.

Request for a quote

TECHNIFLEX

France

Length 1m Width 0.40m Standard automatic inflating Techniflex has been manufacturing shelters with high pressure pneumatic frame for more than ten years. Our TO range is especially suited to lodging, construction sites, technical premises, storage, garage, etc. The features of our shelters are: No metal parts for assembly and disassembly. Small volume when folded. High coverage capacity. Modularity. Techniflex is tough!!! Simple to use, the TO2 tent inflates in minutes, using the high pressure pneumatic system. Ideal for autonomous competitors, it can be easily folded when inflated. It does not need extra air at any times. VERY SOLID RESISTANT TO BAD WEATHER (WINDS OVER 130 KM/H) 5 YEAR GUARANTEE DIMENSIONS Length: 6m Width: 4m Height: 2.5m OPTIONS: Lighting, heating, air-conditioning, hot/cold insulation, etc.

Request for a quoteResults for

Pneumatic systems - Import exportNumber of results

14 ProductsCompany type