- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- nickel alloys

Results for

Nickel alloys - Import export

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products.

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products.

Request for a quote

LEBRONZE ALLOYS

France

Machinining of copper, aluminium, titanium alloys and superalloys.

Request for a quote

NORELEM FRANCE

France

Housing, die-cast zinc. Housing cover, plastic, self-extinguishing. Hinge bolts, die-cast zinc/steel C45. Contacts, silver-nickel alloy 10. Note: The security hinge switches are used for monitoring the position of swing-hinged safety doors, protective hatches and hoods. The protective device is monitored directly in the hinge. By the universally pre-set versions, the switching angle is freely adjustable over the entire working range. A mounting aid ensures the quick alignment to doors and posts. The additional hinges have the same appearance and dimensions as the security hinge switches. The loading values given for the hinges are non-binding reference values without consideration of safety factors and exclude any liability. The values given are for information purposes only and do not constitute a legally binding assurance of properties.

Request for a quote

AXON CABLE SAS

France

Vibraflame® is a range of cables designed to resist extreme temperatures ranging from -196°C to +1565°C.These fire resistant range of cables do not propagate flame and do not contain asbestos. They can be used as control, coaxial or power feed cables. Axon’ offer extension and compensating cables for thermocouples insulated with vibraflame® material and resistant to temperatures of up to 1050°C. These heat resistant cables can be made with nickel plated copper, nickel alloy, nickel chrome, iron, constantan, copper alloy, cupronickel for extension and compensating cable. They are insulated with a special combination of mica, organic polymers and fibre glass. Applications include power and control cables in steel works, oil refinery, electric furnace, blast furnace,etc

Request for a quote

AXON CABLE SAS

France

Axon' offers an extended range of equipment wires and cables for any applications requiring resistance to high temperatures. Different types of constructions can be proposed and delivered ex stock. They are designed to resist high temperatures ranging from -90°C to +260°C depending on the insulation material ; PTFE, ETFE, FEP or polyimide. They are made with silver plated or nickel plated conductor copper alloy, tin, silver or nickel plated copper. They can be used for various applications: aeronautics, automotive, space telecommunications, electronics, military equipment, general industry, ...

Request for a quote

LBI

France

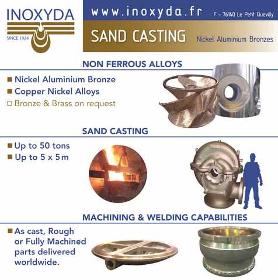

Sand casting of copper alloys, mainly nickel aluminium bronze Maximum weight: 50 tons. Staff: 50 employees. Turnover: approx. 8 M€ 4 et 8 rue Etienne Dolet F-76140 LE PETIT QUEVILLY Tél: +33 (0) 2 35 63 78 50 Fax: +33 (0) 2 35 72 99 99 Internet www.inoxyda.fr E-mail : contact@inoxyda.fr

Request for a quote

LBI

France

We manufacture rough or fully machined feeding tube for nickel processing furnaces in nickel super alloy

Request for a quote

LBI

France

LBI manufactures a wide range of alloys. Our production and material expertise, gained though almost 100 years involvement in the Foundry business, combined with our testing laboratories and control equipment, enables us to meet the very diverse requirements of worldwide market. Below, you can find some of the alloys we produce, listed by family (Heat resisting, Martensitic, Austenitic, Austeno-ferritic& Duplex steels, Nickel based alloys), as well as their approximate equivalent specifications. They constitute only a few examples of our manufacturing potential, so please enquire to our specialist team for all of your requirements. Few examples: G-X 40 CrNiSi 25 12, 1.4840, 1.4848, GX40CrNiSi25-20, 1.4317, CA-15M, CA-6NM, GX3CrNi13-4, 1.4059, GX2CrNiMo19-11-2, 1.4309, 316, 304, 1.4581, 1.4462, 1.4470, CF8M, G-X2CrNiMoN22-5-3

Request for a quote

LBI

France

We manufacture rough or fully machined cage and seat for pressure control valves & control valves in : • Austenitic stainless steel Alloys (CF8M, CF3M…) • Aluminium-Bronze (UNS C95500…) • Duplex and Super Duplex (CD4MCu, CD3MN…) • Nickel-based and high-alloys (CW-6MC, CU5MCuC, M-35-1 CW-12MW…) • Martensitic alloys (CA15, CA6NM…) • Other materials on request

Request for a quote

LBI

France

We manufacture rough or fully machined seat and sealing ring for ball and butterfly valves in : • Austenitic stainless steel Alloys (CF8M, CF3M…) • Aluminium-Bronze (UNS C95500…) • Duplex and Super Duplex (CD4MCu, CD3MN…) • Nickel-based and high-alloys (CW-6MC, CU5MCuC, M-35-1 CW-12MW…) • Martensitic alloys (CA15, CA6NM…) • Other materials on request

Request for a quote

LBI

France

We manufacture rough or fully machined ball and ball trunnion bearing for trunnion mounted ball valve : • Austenitic stainless steel Alloys (CF8M, CF3M…) • Aluminium-Bronze (UNS C95500…) • Duplex and Super Duplex (CD4MCu, CD3MN…) • Nickel-based and high-alloys (CW-6MC, CU5MCuC, M-35-1 CW-12MW…) • Martensitic alloys (CA15, CA6NM…) • Other materials on request

Request for a quote

LBI

France

We manufacture rough or fully machined body and flange for 3 pieces ball valves in : • Austenitic stainless steel Alloys (CF8M, CF3M…) • Aluminium-Bronze (UNS C95500…) • Duplex and Super Duplex (CD4MCu, CD3MN…) • Nickel-based and high-alloys (CW-6MC, CU5MCuC, M-35-1 CW-12MW…) • Martensitic alloys (CA15, CA6NM…) • Other materials on request

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products. Our 16 production facilities and 1,400 employees manage a unique range of metal processing technologies: continuous and semi-continuous casting, sand casting, die precision chill casting (manual, mechanized and automated), centrifugal casting, extrusion, ring rolling, hot and cold rolling, drawing, open-die forging, hot stamping, closed-die forging, cold forming, machining, non-destructive testing, etc. The Group’s commitment is to find appropriate and optimized solutions for every sector’s requirements.

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products. Our 16 production facilities and 1,400 employees manage a unique range of metal processing technologies: continuous and semi-continuous casting, sand casting, die precision chill casting (manual, mechanized and automated), centrifugal casting, extrusion, ring rolling, hot and cold rolling, drawing, open-die forging, hot stamping, closed-die forging, cold forming, machining, non-destructive testing, etc. The Group’s commitment is to find appropriate and optimized solutions for every sector’s requirements.

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products. Our 16 production facilities and 1,400 employees manage a unique range of metal processing technologies: continuous and semi-continuous casting, sand casting, die precision chill casting (manual, mechanized and automated), centrifugal casting, extrusion, ring rolling, hot and cold rolling, drawing, open-die forging, hot stamping, closed-die forging, cold forming, machining, non-destructive testing, etc.

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products. Our 16 production facilities and 1,400 employees manage a unique range of metal processing technologies: continuous and semi-continuous casting, sand casting, die precision chill casting (manual, mechanized and automated), centrifugal casting, extrusion, ring rolling, hot and cold rolling, drawing, open-die forging, hot stamping, closed-die forging, cold forming, machining, non-destructive testing, etc. The Group’s commitment is to find appropriate and optimized solutions for every sector’s requirements.

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in development and production of technical high performance alloys components : copper alloys, nickel alloys, but also aluminium alloys, specialty steels, stainless steels, titanium and nickel supperalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries.

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products. Our 16 production facilities and 1,400 employees manage a unique range of metal processing technologies: continuous and semi-continuous casting, sand casting, die precision chill casting (manual, mechanized and automated), centrifugal casting, extrusion, ring rolling, hot and cold rolling, drawing, open-die forging, hot stamping, closed-die forging, cold forming, machining, non-destructive testing, etc. The Group’s commitment is to find appropriate and optimized solutions for every sector’s requirements.

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products. Our 16 production facilities and 1,400 employees manage a unique range of metal processing technologies: continuous and semi-continuous casting, sand casting, die precision chill casting (manual, mechanized and automated), centrifugal casting, extrusion, ring rolling, hot and cold rolling, drawing, open-die forging, hot stamping, closed-die forging, cold forming, machining, non-destructive testing, etc.

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products. Our 16 production facilities and 1,400 employees manage a unique range of metal processing technologies: continuous and semi-continuous casting, sand casting, die precision chill casting (manual, mechanized and automated), centrifugal casting, extrusion, ring rolling, hot and cold rolling, drawing, open-die forging, hot stamping, closed-die forging, cold forming, machining, non-destructive testing, etc.

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products. Our 16 production facilities and 1,400 employees manage a unique range of metal processing technologies: continuous and semi-continuous casting, sand casting, die precision chill casting (manual, mechanized and automated), centrifugal casting, extrusion, ring rolling, hot and cold rolling, drawing, open-die forging, hot stamping, closed-die forging, cold forming, machining, non-destructive testing, etc. The Group’s commitment is to find appropriate and optimized solutions for every sector’s requirements.

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products. Our 16 production facilities and 1,400 employees manage a unique range of metal processing technologies: continuous and semi-continuous casting, sand casting, die precision chill casting (manual, mechanized and automated), centrifugal casting, extrusion, ring rolling, hot and cold rolling, drawing, open-die forging, hot stamping, closed-die forging, cold forming, machining, non-destructive testing, etc. The Group’s commitment is to find appropriate and optimized solutions for every sector’s requirements.

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products. Our 16 production facilities and 1,400 employees manage a unique range of metal processing technologies: continuous and semi-continuous casting, sand casting, die precision chill casting (manual, mechanized and automated), centrifugal casting, extrusion, ring rolling, hot and cold rolling, drawing, open-die forging, hot stamping, closed-die forging, cold forming, machining, non-destructive testing, etc. The Group’s commitment is to find appropriate and optimized solutions for every sector’s requirements.

Request for a quoteResults for

Nickel alloys - Import exportNumber of results

26 ProductsCompany type