- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- foundry

Results for

Foundry - Import export

LBI

France

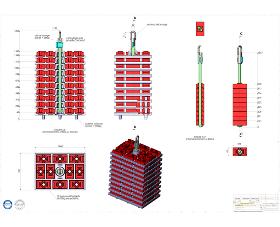

We manufacture rough or fully machined continuous casting moulds in pure copper

Request for a quote

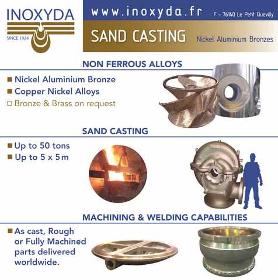

INOXYDA SA

France

We manufacture hub body in aluminium bronze, delivered "as cast" , rough or fully machined according to international quality standards

Request for a quote

INOXYDA SA

France

We cast hub bodies in aluminium bronze uo to 15To , delivered "as cast" , rough or fully machined according to international quality standards. 3rd Party Inspection with Lloyds, Bureau Veritas, DNVGL, RINA, Turkishes Lloyds .

Request for a quote

INOXYDA SA

France

As a specialist of aluminium bronze we provide side solution to sand casting : - continuous casting, - forgings - centrifugal casting in a wide range of aluminium bronze grades

Request for a quote

INOXYDA SA

France

We manufacture body for filter in aluminium bronze, delivered "as cast" , rough or fully machined according to international quality standards

Request for a quote

INOXYDA SA

France

We manufacture FRANCIS runner in aluminium bronze, delivered "as cast" , rough or fully machined according to international quality standards

Request for a quote

INOXYDA SA

France

We cast/machine most valve components in aluminium bronze. We support customers worldwide with "as cast" , rough or fully machined valve components according to international quality standards (EN 1982, BS, ASTM/ASME B148...)

Request for a quote

INOXYDA SA

France

With casting capacities up to 15To and a long experience in sand casting aluminium bronze, we can support most valve projects

Request for a quote

INOXYDA SA

France

All size NAB castings for Valves. Total capacity of 15 To enables to accomodate almost any aluminium bronze project

Request for a quote

LBI

France

Sand casting of copper alloys, mainly nickel aluminium bronze Maximum weight: 50 tons. Staff: 50 employees. Turnover: approx. 8 M€ 4 et 8 rue Etienne Dolet F-76140 LE PETIT QUEVILLY Tél: +33 (0) 2 35 63 78 50 Fax: +33 (0) 2 35 72 99 99 Internet www.inoxyda.fr E-mail : contact@inoxyda.fr

Request for a quote

LBI

France

Sand casting of copper alloys: tin bronzes, lead bronzes, brasses, nickel aluminium bronze, copper and special copper alloys. Maximum weight: 2 tons Staff: 70 employees. Turnover: approx. 10 M€ BP 64 - Rue de l’Embarcadère F - 03600 COMMENTRY Tél. : +33 (0) 4 70 64 58 80 Fax : +33 (0) 4 70 64 64 87 Site web : www.sri-foundry.com E-mail : commercial@sri-foundry.com

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products. Our 16 production facilities and 1,400 employees manage a unique range of metal processing technologies: continuous and semi-continuous casting, sand casting, die precision chill casting (manual, mechanized and automated), centrifugal casting, extrusion, ring rolling, hot and cold rolling, drawing, open-die forging, hot stamping, closed-die forging, cold forming, machining, non-destructive testing, etc. The Group’s commitment is to find appropriate and optimized solutions for every sector’s requirements.

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products. Our 16 production facilities and 1,400 employees manage a unique range of metal processing technologies: continuous and semi-continuous casting, sand casting, die precision chill casting (manual, mechanized and automated), centrifugal casting, extrusion, ring rolling, hot and cold rolling, drawing, open-die forging, hot stamping, closed-die forging, cold forming, machining, non-destructive testing, etc. The Group’s commitment is to find appropriate and optimized solutions for every sector’s requirements.

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products. Our 16 production facilities and 1,400 employees manage a unique range of metal processing technologies: continuous and semi-continuous casting, sand casting, die precision chill casting (manual, mechanized and automated), centrifugal casting, extrusion, ring rolling, hot and cold rolling, drawing, open-die forging, hot stamping, closed-die forging, cold forming, machining, non-destructive testing, etc.

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products. Our 16 production facilities and 1,400 employees manage a unique range of metal processing technologies: continuous and semi-continuous casting, sand casting, die precision chill casting (manual, mechanized and automated), centrifugal casting, extrusion, ring rolling, hot and cold rolling, drawing, open-die forging, hot stamping, closed-die forging, cold forming, machining, non-destructive testing, etc.

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products.

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LEBRONZE ALLOYS

France

Open die forging of copper, aluminium, titanium alloys and superalloys.

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products. Our 16 production facilities and 1,400 employees manage a unique range of metal processing technologies: continuous and semi-continuous casting, sand casting, die precision chill casting (manual, mechanized and automated), centrifugal casting, extrusion, ring rolling, hot and cold rolling, drawing, open-die forging, hot stamping, closed-die forging, cold forming, machining, non-destructive testing, etc. The Group’s commitment is to find appropriate and optimized solutions for every sector’s requirements.

Request for a quote

FONTE GRISE DISTRIBUTION

France

A design office to develop new parts and concepts CAD: modelling, simulation, etc.

Request for a quote

FONTE GRISE DISTRIBUTION

France

Several moulding sites for the diversity of shapes Traditional: shake/pressure, automated: for small and medium production runs Ultra-automated: DISAMATIC-type vertical parting line moulds, with unrivalled formats and surface finishes: parts weighing up to 200kg per mould with a tooling format of 1200x1050 mm. Manual, on the floor: unit production and production of non-standard formats.

Request for a quote

FONTE GRISE DISTRIBUTION

France

FGD helps you develop your parts and takes charge of your production, from the moment it leaves the foundry to its final destination, optimising the management of your stocks and flows. EN-GJL-150/200/250 EN 1561, EN-GJS-400-15/500-7 EN 1563 Expertise in the control of additives for specific constraints on the use of cast iron: machining, operating temperature, etc.

Request for a quote

FONTE GRISE DISTRIBUTION

France

Adapted logistics resources for fast response times and optimised stock management Weekly shuttles between France and Poland Deliveries within 72 hours in France for items managed by FGD.

Request for a quote

FONTE GRISE DISTRIBUTION

France

Paint shops to protect parts from corrosion and enhance their appearance Primer paint to specification RAL colour chart, any colour on request after matching.

Request for a quoteResults for

Foundry - Import exportNumber of results

25 ProductsCountries

Company type