- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- follow machines

Results for

Follow machines - Import export

CHOQUENET SAS

France

Maintenance and expertise With a team of more than 15 people, we put all our resources at your disposal to ensure a global and complete follow-up of your machines. Our experts intervene all over the world in order to guarantee you the best performance of our equipment. We have several mechanics and hydraulic engineers who will help you in the management of corrective maintenance Our offer extends over several fields, from the simple replacement of worn parts to the advanced optimization of the performance of our machines with the support of our automation specialists and engineers. As preventive maintenance has become a major issue in recent years, we also offer maintenance and monitoring contracts for installations, thus ensuring the reliability of your installations with complete peace of mind.

Request for a quote

MECANUMERIC

France

Fixed table, mobile laser, average power. Sealed laser sources from 100 to 600W enable to get a very low operating cost because these laser do not require exterior laser gas and they have a life time of 15000 to 18000 hours, before any gas reloading. CUTTING EQUIPMENT OPTIMIZED FOR MACHINING OF FOLLOWING MATERIALS WITH STANDARD FOCUSING HEADS : . Acrylic . Plastic materials . Wood and by-products THE UTILIZATION OF A FOCUSING HEAD WITH HIGH PRESSURE LENS GIVES THE POSSIBILITY TO CUT IN ADDITION : . Soft steel : thickness 4 mm with 300W, 6 mm with 600W . Stainless steel : thickness 1,5 mm with 350W, 3 mm with 600W Fast, rigid and accurate equipment, three available sizes in standard Travel in mm X Y Z MECALASE ML 3015 3050 1510 195 MECALASE ML 3020 3050 2020 195 TECHNOLOGIES : . Transmission by 4 ball screws (2 ball screws on X axes), numerical Z axis . Motorisation : 4 DC servomotors with continuous current . Guidance : precision linear rails with preloaded ball slides ....

Request for a quote

MECANUMERIC

France

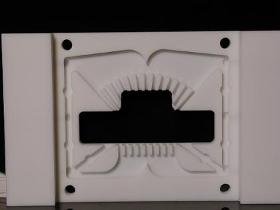

This new 3 axis CNC machine range has been entirely modified in 2006. Completely covered, this equipment is in conformity with CE norms. Refer to the exemples of applications : Moulds and models EDM electrodes Bronze medal Telephone casing model MACHINING CENTER FOR 3D PRECISION ENGRAVING AND MOULDS , MODELS, ELECTRODES OR PUNCHES REALIZATION EQUIPMENT OPTIMIZED FOR THE MACHINING OF FOLLOWING MATERIALS: . Aluminium . Synthetic resins . Steel . Brass and copper alloys . Plastics and composites . Graphite AVAILABLE SIZE: Model X travel mm Y travel mm Z travel mm TR 75 520 750 325 TECHNOLOGY: . Kinematic unit with fixed table and mobile gantry. . Steel welded frame. . Steel welded mobile gantry . Vacuum table in aluminium profiles or composite . Holding of plates by vacuum generated either by lateral canal turbines or by vacuum claw pumps. Selection of zones with manual valves. . Motorisation by AC Brushless servomotors on the 4 axes (X1-X2-Y-Z), double driving on X axis. ....

Request for a quote

MICROCERTEC

France

Macor® is most used for its machinability. Softer as the other ceramic materials, Macor® allows fast turnaround to obtain complex structures with tight tolerances. Macor® can be grinded and facilitate the drilling and milling operations. Selection of materials Microcertec uses Macor® from the comapny Corning. Macor® is a glass ceramic from Silica (50%) and also with Magnesium und Aluminium. Properties Macor® have the following features : machinability good electrical insulation good thermal insulation dimensional stability vacuum resistant Our typical applications Macor® is widely used in the following applications : tools for the machine in production insulator electrode holders sensor holders lense holders mulberry outlet Download Material properties datasheet : ceramics and quartz (1472 Ko)

Request for a quote

MICROCERTEC

France

Macor® is mainly used for its machinable properties. Because it is softer than advanced ceramics, Macor® permits to achieve complex geometries more rapidly with the same level of accuracy. In addition to be able to be ground like other ceramics, Macor® can be machined with carbide tools which make drilling and milling easier. Products Macor® is mainly used to manufacture the following products : tooling parts for production machinery insulators electrode carriers lens holders sensor carriers Materials Microcertec utilizes Macor® made by Corning. Macor® is a glass ceramic the chemical composition of which is mainly borosilicate to about 75 %, alumina and magnesia. Macor® has the following properties : machinable good electrical insulation good thermal insulation dimension stability to about 800°c vacuum compatible Download Precision machining of Macor (374.69 Ko)

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Follow machines - Import exportNumber of results

5 ProductsCountries

Company type

Category