- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- filling

Results for

Filling - Import export

CDA

France

The K-Line S stands out as an enclosed linear filling machine, appreciated not only for its user-friendly nature and self-cleaning capabilities but also for its remarkable versatility. Tailored to the specific characteristics of your products, we employ the appropriate dosing system—be it volumetric, flowmetric, centrifugal dosing, among others. Remarkably, the K-Line S achieves a filling capacity of up to 3,000 liters per hour while maintaining a high level of accuracy at +/- 0.5%. Complementing this, the VS1000 capper, seamlessly integrated with a linear conveyor (or curved to suit your workshop layout), is also fully enclosed. This capping powerhouse accommodates an extensive range of caps, leveraging an electric screwdriver-operated capping system ideal for various cap types, including gun caps, spray caps, dropper caps, and more. To complete the packaging line, the Ninon Mix labelling machine takes center stage.

Request for a quote

CDA

France

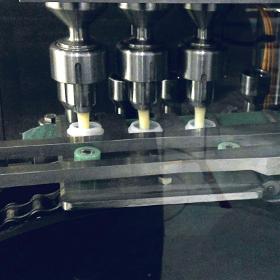

The complete line for small products integrates three crucial phases of packaging: filling, screwing, and labeling. Ideal for small-scale productions with outputs reaching up to 15 products per minute (900 products per hour), this configuration caters to cylindrical products within the 5ml to 250ml range. Suited for various industries, including pharmaceuticals, cosmetics, food, and e-liquids, this comprehensive line ensures efficiency and versatility.

Request for a quote

CDA

France

On this line, filling is provided by the K Net Auto, an automatic machine that can fill up to 1,200 products / hour with an accuracy of +/- 0.5% of the dosed liquid. Depending on your industry and your product range, the K Net Auto will be equipped with a suitable dosing system (peristaltic, flowmeter, volumetric, etc.). Capping is carried out using the VS 400. This automatic capper is versatile and allows the capping of many cylindrical caps (caps with vertical grooves, dropper caps, pre-threaded screw caps, screw caps, hinged lids, etc. etc.). The operator manually places the cap onto the container which will then be detected and then automatically be capped (tightening torque set via the touch screen) by the capping head. Finally, the labeling is carried out by the Ninon Mix machine. This labeler is one of the most versatile in the CDA range. Square, cylindrical, oval, tapered products … Our labeler covers all of these containers with one to several labels.

Request for a quote

CDA

France

The CDA K-Dense stands as an automatic filling machine meticulously crafted by our design team, offering a versatile 2-in-1 functionality. As a dosing table, the K-Dense not only automatically dispenses containers along a packaging line but also simultaneously fills them. This innovative filing system presents several advantages: Space Efficiency: The dosing process takes place directly on the infeed table, minimizing space requirements. Easy Cleaning: Cleaning operations are simplified as there's no need to access the conveyor; you can conveniently clean the accessible table. Fitted with either a piston pump or gear pump tailored to your product specifications, the K-Dense dosing table accommodates various glass jar formats with twist-off caps or wide-opening plastic jars (150g, 200g, 250g, 500g, etc.) suitable for thick, pasty, or semi-dense products like jam, honey, maple syrup, sauces, mustard, spreads, and more.

Request for a quote

CDA

France

In our lineup of equipment, the K-Line S takes the spotlight as an enclosed linear filler, celebrated for its user-friendly interface and easy adjustability. Renowned for its exceptional versatility, this machine is highly regarded for its efficient cleanability. With the K-Line S, achieving a filling capacity of up to 3,000 liters per hour is possible while maintaining an accuracy of +/- 0.5% of the dosed volume. Integrated into the production flow using a linear conveyor (or a curved/U-shaped design, depending on your workshop layout), the VS2000 capping machine effortlessly handles the automatic feeding and capping of a diverse range of closures. The final phase of the packaging line is seamlessly executed by the Ninon Mix labeller, which can also be configured for cartoning upon request. The Ninon Mix stands out for its impressive versatility, capable of applying up to 5 self-adhesive labels.

Request for a quote

CDA

France

The K-Dy, a semi-automatic filling machine crafted by CDA, caters specifically to drums and tanks. Engineered with a recommended minimum dosage of 5 litres, it can efficiently fill up to 1,000 litres utilizing its remote filler. The K-Dy excels in dispensing precise and substantial doses, accommodating a diverse range of products from fluids to those with a slight thickness. Its adaptability to various dispensing systems, including electromagnetic or mass flow meters, makes the K-Dy well-suited for an array of industries, including food and chemicals.

Request for a quote

CDA

France

Fitted with a stainless steel conveyor, the CDA K-Net Auto linear automatic filler facilitates the automatic dosing and filling of various liquid types, ensuring strict adherence to hygiene standards. Tailored to accommodate diverse formats and a broad spectrum of products, the K-Net Auto finds applicability across multiple industries, including: Food Processing: Suitable for liquids like vinegar, oil, fruit juice, honey, and jam. Cosmetics: Ideal for products such as perfume, soap, ointment, and body oil. Paint and Varnish Industry: Efficiently handles buckets, paint, and varnish pots. Chemicals: Apt for dosing detergent, solvent, and similar products. Impressing users with its precision, user-friendly interface, and ease of cleaning, the K-Net Auto operates through an intuitive touch screen control system.

Request for a quote

CDA

France

The K-Line S stands out as an automatic dosing and filling machine designed to accommodate a wide range of liquid types. Its versatility extends to handling various product consistencies, including fluids, foaming liquids, and thick or pasty viscosities. Tailoring its functionality to the viscosity of the intended products, the machine is equipped with a suitable pump. Configured with either a magnetic or mass flow meter, the K-Line S features a pressurized tank renowned for its effective self-cleaning system. Boasting remarkable precision, the K-Line S ensures the automatic centering of products. It is configurable with 2 to 6 filling nozzles, with the option of immersion nozzles for foaming products. The machine achieves an impressive filling rate of up to 3000 liters per hour.

Request for a quote

SYNERLINK

France

Our RM90C cup filling machine for preformed cups is known for its extremely high flexibility. Our equipment is designed to make all operations at ground level. Our gentle multi-layers well-known filling capability is ideal for premium dairy products with high accuracy. The filling volume goes from 80 to 1,500 ml with multi-flavors capability at a speed up to 30,000 cups per hour with double index. Our machine can handle paper, plastic, aluminum and glass cups. With up to three different cup diameters from 60 to 160mm, RM90C is optimal for industries where outstanding flexibility and line efficiency are critical. Over cap dispensing and clipping can be integrated.

Request for a quote

SYNERLINK

France

The VERSA cup filling machine allows you to adapt to your customers' needs and diversify your offering by accepting and processing cups of different shapes, materials, diameters and heights with a format changeover as quick as 20 minutes. The VERSA cup filling machine is designed for fast and easy cleaning with removable slats. No tools are required, while the fast-return system reduces the number of slats required. Employees’ well-being on the job is not constraint to safety. The VERSA cup filling machine abides by all safety regulations and its ergonomic design improves the day-to-day on your plant. With a chest-high loading station and dedicated tables for containers or boxes, the operator’s movement are optimized. The high visibility throughout the whole production process assures the correct functioning of the machine and the adjustments to the slats’ changeovers, transparency, weight and size allows for a reduced risk of error.

Request for a quote

SYNERLINK

France

Our DN200 thermoforming machine is known for its very compact footprint and small budget. Its simplicity and compactness are ideal for small productions and product tests up to 5,400 cups/hour or 10,800 miniportions/hour. Our equipment is designed to make all operations at ground level. FFS packages are shipped in plastic reels and thermoformed in your plant. Cups are filled and sealed in ultra-clean conditions. The filling volume goes from 10 to 240 ml. Our machine can handle various materials (PS, PP, multilayer). DN200 is optimal for industries where flexibility and affordability are critical.

Request for a quote

SYNERLINK

France

Our DP60C cup filling machine for preformed cups is known for its extremely accurate filling and gentle multi-layers product. Its compact footprint and high cost efficiency are ideal for small to medium production lines. Our equipment is designed to make all operations at ground level. The filling volume goes from 100 to 1,000 ml at a speed up to 18,000 cups per hour with multi-flavors capability. Our machine can handle paper, plastic and aluminum cups. With simple or double index of 50 to 120mm cup diameter, DP60C is optimal for industries where compacity and line efficiency are critical.

Request for a quote

SYNERLINK

France

Our RM12B bottle filling machine for preformed bottles is known for its extremely high filling accuracy. We can deliver a wide range of decontamination levels according to shelf-life need and storage conditions. This machine high flexibility and technical efficiency are ideal for medium beverage lines. Our equipment is designed to make all operations at ground level. The filling volume goes from 80 to 1,000 ml at a speed up to 50,000 bottles per hour. Our machine can handle various materials (PET, HDPE, PP, PS) with optional screw capping. With one or two neck diameters, 40 to 92mm body diameter and multi-flavors filling, RM12B is optimal for industries where flexibility and line efficiency are critical.

Request for a quote

SYNERLINK

France

Our RM80B bottle filling machine for preformed bottles is known for its extremely high filling accuracy. We can deliver a wide range of decontamination levels according to shelf-life need and storage conditions. This machine compact footprint and cost-efficiency are ideal for medium beverage lines. Our equipment is designed to make all operations at ground level. The filling volume goes from 80 to 1,500 ml at a speed up to 24,000 bottles per hour. Our machine can handle various materials (PET, HDPE, PP, PS) with optional screw capping. With one or two neck diameters, 40 to 88mm body diameter and multi-flavors filling, RM80B is optimal for industries where flexibility and line efficiency are critical.

Request for a quote

SYNERLINK

France

Based on the architecture of RM25B, our RM40B bottle filling machine for preformed bottles offers increased volume capacity and higher speeds. We can deliver a wide range of decontamination levels according to shelf-life need and storage conditions. This machine compact footprint and cost-efficiency are ideal for small beverage lines. Our equipment is designed to make all operations at ground level. The filling volume goes from 80 to 1,500 ml at a speed up to 12,000 bottles per hour. Our machine can handle various materials (PET, HDPE, PP, PS) with optional screw capping. With one or two neck diameters, 40 to 88mm body diameter and multi-flavors filling, RM40B is optimal for industries where flexibility and line efficiency are critical.

Request for a quote

SYNERLINK

France

Our RM25B bottle filling machine for preformed bottles is known for its extremely high filling accuracy. We can also deliver a wide range of decontamination levels according to shelf-life need and storage conditions. This machine's compact footprint and cost-efficiency are ideal for small beverage lines. Our equipment is designed to make all operations at ground level. The filling volume goes from 80 to 270 ml at a speed up to 6,000 bottles per hour. Our machine can handle various materials (PET, HDPE, PP, PS) with optional screw capping. With one or two neck diameters, 40 to 56mm body diameter and multi-flavors filling, RM25B is optimal for industries where flexibility and line efficiency are critical.

Request for a quote

SYNERLINK

France

Our RM12C cup filling machine for preformed cups is known for its extremely high flexibility. Our equipment is designed to make all operations at ground level. Our gentle multi-layers well-known filling capability is ideal for premium dairy products with high accuracy. The filling volume goes from 80 to 1,500 ml with multi-flavors capability at a speed up to 60,000 cups per hour with double index. Our machine can handle paper, plastic, aluminum and glass cups. With up to three different cup diameters from 60 to 160mm, RM12C is optimal for industries where outstanding flexibility and line efficiency are critical. Over cap dispensing and clipping can be integrated.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ENVEA

France

Microwave barrier for contactless detection of dry bulk solids in containers, pipes or chutes. Reliable fill level and limit detection. • simple retrofitting • detection through all nonconductive walls • up to 1,000 °C possible with ceramic mounting • insensitive to material caking • usable for profiles up to 25 m

Request for a quote

LOUISON INDUSTRIES

France

Louison Industries manufactures made-to-measure cords, offering a wide range of solutions for a variety of sectors. Thanks to our in-depth expertise, we design and manufacture high-quality cords to meet the specific requirements of each industry: Solutions for luxury packaging: Elegant and resistant cords to enhance your luxury products and strengthen the customer experience. Military cords: robust and reliable cords for demanding military applications, guaranteeing optimum performance in the most demanding environments. Diameter: 1 to 10 mm thick Texture: Flat, round, rigid or elastic - traditional or technical. Composition: All types of materials (Polyester, Polyamide, Polypropylene, Cotton, Aramid and Para-Aramid (Nomex®, Kevlar®, Trevira®, Dyneema®, etc.), Glass fibre, Recycled materials...) Treatment: M1 fire-resistant/hydro-repellent coating/UV resistance, etc. Dyeing: Wide range of colours

Request for a quote

LOUISON INDUSTRIES

France

Textile overmoulding has a wide range of applications in various industrial sectors. Our customers in the automotive, electronics, sports, medical and other sectors benefit from our expertise in textile overmoulding to design bespoke parts to meet their specific needs. In the automotive sector: it improves occupant comfort by providing a softer feel. It can also improve soundproofing and thermal insulation. Discover the overmoulded part, a mechanical link between two parts, a textile support and an injected plastic part, in a permanent manner. Overmoulding offers a number of advantages: No gluing stage in the manufacturing process High design flexibility Prevents components from coming loose Production of multi-material components Improved resistance to shock and vibration Improved strength and structure of parts

Request for a quote

CDA

France

CDA provides a piston pump trolley designed for pumping high-density products, offering various piston capacities to cater to the required dose and capacity. This portable trolley ensures precise dosing accuracy and is versatile enough to be adapted to monoblocks and filling machines like: The K-Net (semi-automatic filling machine), The K-Net Auto (automatic filling machine), The K-Line S (automatic linear filler).

Request for a quote

CDA

France

The E-Fill SW Dropper monoblock is designed for enhanced versatility in packaging bottles ranging from 5 to 250 ml in various formats. This model stands out as it is tailored for filling, screwing, and labelling vials with a pipette cap, suitable for products like CBD oils and serums in the cosmetic sector. Equipped with an external vibrating bowl to automatically align the caps, the E-Fill SW Dropper uses a vibrating ramp to convey the caps into the machine. For added safety, a clamp guides the glass dropper into the container, preventing breakage.

Request for a quote

CDA

France

CDA’s E-Fill SW Monoblock is designed to deliver exceptional performance and adaptability to the fully automatic packaging line from which it originates. This SW version excels in the filling, screwing, and labelling of bottles (e-liquid, essential oils, flavours, dyes, reagents…) ranging from 5 to 250ml in various formats. It operates in two modes: Fully automatic mode for large product series, utilizing the Pick & Place system for automatic cap positioning and screw capping. "Switch" mode caters to small and medium product series, incorporating manual cap dispensing on the bottle and automatic screw capping. The switch mode facilitates the bottling of different product formats without complex handling or adjustments. Doors can be opened to allow an operator to manually dispense caps, which are then automatically capped on filled bottles by a specific automatic capper. With a speed of up to 3000 bottles/hour, the E-Fill SW can be equipped with up to 2 labelling stations.

Request for a quote

CDA

France

Initially designed for the e-liquid industry, the E-Fill is an ultra-compact filling, labelling, and screw-capping machine that exceeds the most stringent requirements for filling and labelling e-liquid bottles for e-cigarettes. Its versatility now allows adaptation to other industries such as food processing (flavours, oil, etc.) or cosmetics (cream, liquid soap, etc.) due to innovative features, including the handling of products ranging from 5mL to 1L with a maximum diameter of 90mm. Featuring a peristaltic pump system, the E-Fill enables a quick liquid change in less than 2 minutes without requiring pump cleaning. Additionally, it can be equipped with a volumetric pump, utilizing a flow meter or piston, depending on the viscosity of the product being filled. The comprehensive E-Fill packaging line can apply up to 2 labels and achieve a filling rate of up to 25 products per minute.

Request for a quote

CDA

France

The CDA K-Net stands out as a semi-automatic filling machine designed for dosing and filling various liquid types, including fluids, viscous, and pasty substances, with an optional screwing system. Adaptable to different pumping systems, the K-Net finds compatibility with products spanning diverse sectors: Food processing (honey, oil, mustard, fruit juice, etc.), Paints and varnishes, Cosmetics (cream, ointment, body oil, etc.), Chemical industry (detergent, solvent, household products, etc.). Utilizing either an electromagnetic or mass flow meter based on the product type, the K-Net achieves an optimal production rate suitable for small and medium-scale operations, reaching up to 600 vials/hour, contingent on the product and container specifications.

Request for a quote

CDA

France

Designed by CDA engineers using top-tier materials available in the market, the peristaltic filling pump, known as the K-One, is highly regarded for its precision and adaptability. CDA's K-One peristaltic pump is suitable for use in both automatic and semi-automatic dosing machines. It functions seamlessly within a comprehensive packaging line and can also be employed in a "manual" capacity for packaging smaller production quantities. The peristaltic technology incorporated into the K-One offers numerous advantages: The product remains untouched by the pump. Hose changes are quick and straightforward. Cleaning time is minimized. The set dose can be automatically corrected after inputting the actual dose obtained during adjustment. Waste-free start-up is achieved via a priming button. Rapid cleaning is facilitated without any loss of product through reverse rotation.

Request for a quote

CDA

France

The C-Pills, a semi-automatic machine designed for counting capsules and film-coated tablets, is a product of CDA tailored specifically for the pharmaceutical, food, and animal feed industries. It distinguishes itself through its robust construction, utilizing premium materials such as mirror-polished stainless steel, glass, and food-grade plastic (POM c). Operating with efficiency, the C-Pills relies on a vibrating hopper for a consistent supply of tablets and capsules to the rotary table. These pharmaceutical items are then guided with precision along the periphery of the Rotary Glass Table. As they move, they drop into a counting airlock, creating optimal spacing between each item through a laser curtain, facilitating accurate counting. With an impressive counting capacity of 1,000 capsules or tablets per minute (for size 0), the C-Pills ensures maximum productivity, meeting the high demands of the pharmaceutical industry.

Request for a quote

BCL INVENT

France

Asbestos Easygel Protect® drilling solutions guarantee a dusting This performance is achieved in compliance with the product instructions, in a regulatory operations and adequate staff training. The solution is suitable for all types of dust harmful or not (Asbestos / Lead / Silica / Dusts,…). SPECIFICATIONS • Capture and retention of all dusts at the source (Asbestos / Lead / Silica / Dusts,…) • Predosed and ready to use product • Transparent and nonharmful gel BENEFITS • Cheap Solution • Easy to use • Reproducible operating mode • Clean Site • Protection of operators and their environment

Request for a quote

BCL INVENT

France

Capture and retention of all dusts at the source. The solution is suitable for all types of dust harmful or not (Asbestos / Lead / Silica / Dusts,…). Each gel, specifically developed according to its application, allow you to reduce dusting. This performance is achieved in compliance with the product instructions, in a regulatory operations and adequate staff training. SPECIFICATIONS • Capture and retention of all dusts at the source (Asbestos / Lead / Silica / Dusts,…) • Predosed and ready to use product • Transparent and nonharmful gel BENEFITS • Cheap Solution • Easy to use • Reproducible operating mode • Clean Site

Request for a quoteResults for

Filling - Import exportNumber of results

42 ProductsCountries

Company type