- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cups

Results for

Cups - Import export

SYNERLINK

France

Our DN200 thermoforming machine is known for its very compact footprint and small budget. Its simplicity and compactness are ideal for small productions and product tests up to 5,400 cups/hour or 10,800 miniportions/hour. Our equipment is designed to make all operations at ground level. FFS packages are shipped in plastic reels and thermoformed in your plant. Cups are filled and sealed in ultra-clean conditions. The filling volume goes from 10 to 240 ml. Our machine can handle various materials (PS, PP, multilayer). DN200 is optimal for industries where flexibility and affordability are critical.

Request for a quote

SYNERLINK

France

Our RM12C cup filling machine for preformed cups is known for its extremely high flexibility. Our equipment is designed to make all operations at ground level. Our gentle multi-layers well-known filling capability is ideal for premium dairy products with high accuracy. The filling volume goes from 80 to 1,500 ml with multi-flavors capability at a speed up to 60,000 cups per hour with double index. Our machine can handle paper, plastic, aluminum and glass cups. With up to three different cup diameters from 60 to 160mm, RM12C is optimal for industries where outstanding flexibility and line efficiency are critical. Over cap dispensing and clipping can be integrated.

Request for a quote

SYNERLINK

France

Our RM90C cup filling machine for preformed cups is known for its extremely high flexibility. Our equipment is designed to make all operations at ground level. Our gentle multi-layers well-known filling capability is ideal for premium dairy products with high accuracy. The filling volume goes from 80 to 1,500 ml with multi-flavors capability at a speed up to 30,000 cups per hour with double index. Our machine can handle paper, plastic, aluminum and glass cups. With up to three different cup diameters from 60 to 160mm, RM90C is optimal for industries where outstanding flexibility and line efficiency are critical. Over cap dispensing and clipping can be integrated.

Request for a quote

SYNERLINK

France

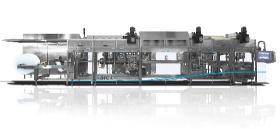

Our AR700 cup thermoforming machine is known for its user friendliness, great reliability, simple design and layout. Our gentle multi-layers well-known filling capability is ideal for premium dairy products with high accuracy. Its high adaptability to changing market needs and easy operation and maintenance are ideal for high speed production lines. Our equipment is designed to make all operations at ground level. FFS packages are shipped in plastic reels and thermoformed in your plant. Cups are filled and sealed in ultra-clean conditions at a speed up to 57,600 cups per hour. Our machine can handle various materials (PS, PET, PLA, PP, multilayer) and deliver wide range of conical, straight and open mold cups with or without label.

Request for a quote

SYNERLINK

France

The VERSA cup filling machine allows you to adapt to your customers' needs and diversify your offering by accepting and processing cups of different shapes, materials, diameters and heights with a format changeover as quick as 20 minutes. The VERSA cup filling machine is designed for fast and easy cleaning with removable slats. No tools are required, while the fast-return system reduces the number of slats required. Employees’ well-being on the job is not constraint to safety. The VERSA cup filling machine abides by all safety regulations and its ergonomic design improves the day-to-day on your plant. With a chest-high loading station and dedicated tables for containers or boxes, the operator’s movement are optimized. The high visibility throughout the whole production process assures the correct functioning of the machine and the adjustments to the slats’ changeovers, transparency, weight and size allows for a reduced risk of error.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SYNERLINK

France

Our DN250 cup thermoforming machine is known for its compact footprint and high cost efficiency. Our gentle multi-layers well-known filling capability is ideal for premium dairy products with high accuracy. Our equipment is designed to make all operations at ground level. FFS packages are shipped in plastic reels and thermoformed in your plant. Cups are filled and sealed in ultra-clean conditions at a speed of 18,700 to 43,200 cups per hour. Our machine can handle various materials (PS, PET, PP, multilayer) and deliver wide range of conical and straight cups with or without label.

Request for a quote

SYNERLINK

France

Our DP60C cup filling machine for preformed cups is known for its extremely accurate filling and gentle multi-layers product. Its compact footprint and high cost efficiency are ideal for small to medium production lines. Our equipment is designed to make all operations at ground level. The filling volume goes from 100 to 1,000 ml at a speed up to 18,000 cups per hour with multi-flavors capability. Our machine can handle paper, plastic and aluminum cups. With simple or double index of 50 to 120mm cup diameter, DP60C is optimal for industries where compacity and line efficiency are critical.

Request for a quote

ADIS FRANCE

France

drains (single-function suction cups) to remove air pockets from pressurised pipes KEY FEATURES - Built-in operation monitor - Ductile iron body EN-GJS 400 - Blue epoxy anti-corrosion coating - Minimum pressure: 0.1 bar - For brass 1/4 turn shut-off valve - Operating temperature: 1°C to 70°C - Flange drilling to EN1092-2 standard - A.C.S. certified product

Request for a quote

ACIMEX

France

How does vacuum handling work? Vacuum handling using suction cups is simple. A pump sucks in the vacuum between the suction cup and the part to be lifted, and stores this vacuum in a chamber dedicated for this purpose. By creating a vacuum, the atmospheric pressure is eliminated in the suction cup enclosure. The product is then pressed against the suction cup by this same atmospheric pressure of 1 kg/cm² (which varies from 950 to 1030 hectopascals); consequently, on a suction cup of 1 m² there is a pressure of 10,000 kg, making it capable of raising this same load. This physical phenomenon makes handling by suction cups an extremely efficient and reliable technique, capable of performing a very large number of handling operations.

Request for a quoteResults for

Cups - Import exportNumber of results

10 ProductsCountries

Company type