- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- compounds

Results for

Compounds - Import export

SEMIN

France

COMPOSITION AND APPEARANCE Powder filler based on plaster, calcium carbonate and various additives. The resulting paste is white. SUPPORT AGREED All types of interior substrates. COATINGS DTU 59.1. MATERIALS AVAILABLE DTU 59.1 TECHNICAL CHARACTERISTICS • Setting time : 2 hours • Particle size : fine SUITABLE SURFACES The substrates must be in conformity with DTU 59.1, i.e., clean, hard, free of dust and any trace of release agent. Scrape down, sand and wash old paint. USE CAUTION The temperature during application and drying must be between 5 and 30°C. Do not apply to a damp substrate. Do not use mix that has begun to harden. RATE TEMPERING Around 10 to 12 l of water per 25 kg sack. Mixing is preferably to be carried out mechanically. APPLICATION Application is to be carried out using a float, a knife or a putty knife for smoothing. For a decorative finish, use a roller, brush or sponge.

Request for a quote

ENVEA

France

The VOC72M’s metrology, in accordance with EN 14662-3 (2005) & EN 15267-1 (2009) standard for benzene measurement, is based on gas chromatography (GC) coupled with a photo-ionization detector (PID).

Request for a quote

ENVEA

France

Gas chromatography (GC) coupled with a PID detector. VOC monitor QAL1 certified to EN 14662-3, the newest standard for benzene measurement.

Request for a quote

LOUISON INDUSTRIES

France

Louison Industries manufactures made-to-measure cords, offering a wide range of solutions for a variety of sectors. Thanks to our in-depth expertise, we design and manufacture high-quality cords to meet the specific requirements of each industry: Solutions for luxury packaging: Elegant and resistant cords to enhance your luxury products and strengthen the customer experience. Military cords: robust and reliable cords for demanding military applications, guaranteeing optimum performance in the most demanding environments. Diameter: 1 to 10 mm thick Texture: Flat, round, rigid or elastic - traditional or technical. Composition: All types of materials (Polyester, Polyamide, Polypropylene, Cotton, Aramid and Para-Aramid (Nomex®, Kevlar®, Trevira®, Dyneema®, etc.), Glass fibre, Recycled materials...) Treatment: M1 fire-resistant/hydro-repellent coating/UV resistance, etc. Dyeing: Wide range of colours

Request for a quote

LOUISON INDUSTRIES

France

Textile overmoulding has a wide range of applications in various industrial sectors. Our customers in the automotive, electronics, sports, medical and other sectors benefit from our expertise in textile overmoulding to design bespoke parts to meet their specific needs. In the automotive sector: it improves occupant comfort by providing a softer feel. It can also improve soundproofing and thermal insulation. Discover the overmoulded part, a mechanical link between two parts, a textile support and an injected plastic part, in a permanent manner. Overmoulding offers a number of advantages: No gluing stage in the manufacturing process High design flexibility Prevents components from coming loose Production of multi-material components Improved resistance to shock and vibration Improved strength and structure of parts

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

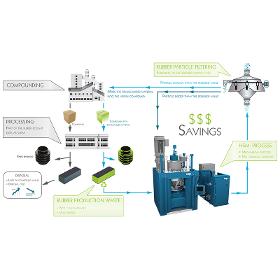

REP INTERNATIONAL

France

The purpose of HSM (High Shear Mixing) technology consists in devulcanizing rubber waste for reintroduction into the production chain. This patented process applies to any kind of uncontaminated rubber production waste. REP has developed a machine dedicated to this process. The installation and maintenance of the machine are supported by the REP network.

Request for a quote

REP INTERNATIONAL

France

REP studies your solution! REP answers questions that cannot be resolved using conventional techniques. An "advanced" competence accompanied by the guarantees of the REP GROUP! A team of engineers is at your disposal for the study and realization of presses for special applications. A REP solution for every problem! We are able to meet your most complex requirements,

Request for a quoteResults for

Compounds - Import exportNumber of results

8 ProductsCompany type