- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- mills

Results for

Mills - Import export

STEEC

France

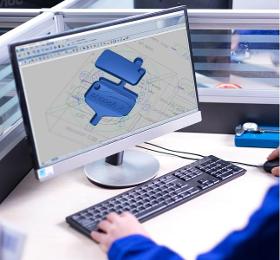

STEEC is able to carry out milling and micro-milling operations on complex mechanical parts with increasingly finer dimensions and increasingly tighter tolerances. STEEC carries out micro-drilling operations to manufacture not only parts but also very high precision electrodes. That enable all spark erosion micro-drilling and countersinking operations to be performed. Equipped with a stock of high-tech machines and leading edge IT tools, such as the Solidworks software, STEEC is capable of meeting special requirements and providing innovative solutions for each of its customers. The experience gained in other high precision machining technologies has enabled STEEC to develop innovative milling processes that are well recognized in the industrial environment.

Request for a quote

STEEC

France

At its 4 CN machining centres STEEC drills and taps holes of very small dimensions down to diameters of a few tenths of microns. STEEC carries out micro-drilling work on conventional machining centres. STEEC is able to machine parts in small and medium series or units parts that may have several tens of thousands of holes per parts. The company has acquired know-how and expertise recognized by multiple audits by major contractors in this technology. These audits have also led to special prestigious certifications. This technical solution may be applied in all industrial sectors, from aerospace to the medical sector, also including research or the automotive industry.

Request for a quote

KRAFFTER MACHINE TOOLS

France

Year of manufacturing : 2020 CNC control : HEIDENHAIN TNC 640 Number of simultaneous axes : 5 Stroke X axis : 650 mm Stroke Y axis : 850 mm Stroke Z axis : 500 mm Traversing feeds X, Y and Z axes : 36000 mm/min X axis ball screw, Ø x pitch : 40 x 12 mm Y axis ball screw, Ø x pitch : 40 x 12 mm Z axis ball screw, Ø x pitch : 40 x 12 mm Angular A axis stroke : +/- 120 ° Angular C axis stroke : 360 ° Min. distance spindle nose / table : 150 mm Max. distance spindle nose / table : 650 mm Spindle type : HSK-A 63 Max. spindle speed : 20000 rpm Tool changer magazin number of stations : 60 Max. tool length : 300 mm Max. weight of single tool : 8 Kg Total max. weight in tool changer magazine : 480 Kg Max. tool diameter : 125 mm Total power required : 60 kVA Number of hours under power : 5683 h Number of running hours : 3183 h Machine weight : 12000 Kg Machine dimensions : 3390 x 3940 x 2970 mm With equipment

Request for a quote

KRAFFTER MACHINE TOOLS

France

TECHNICAL CHARACTERISTICS : Year of manufacturing : 2018 CNC control : HEIDENHAIN iTNC 640 Number of simultaneous axes : 5 Stroke X axis : 2000 [mm] Stroke Y axis : 600 [mm] Stroke Z axis : 550 [mm] Feed rate on X, Y and Z axes : 20000 [mm/min] Traversing feeds X, Y and Z axes : 40000 [mm/min] Axes acceleration : 2.5 [mm/sec²] Min. distance spindle nose / table : 30 [mm] Table length : 1250 [mm] Table width : 800 [mm] Max. load on table : 500 [Kg] Rotary tilting table surface : 600 x 600 [mm] Stroke C axis : table revolution : 360 [°] Max. speed C axis : 25 [rpm] B axis swivelling stroke : -110 / +110 [°] Spindle type : ISO 40 Max. spindle speed : 15000 [rpm] Spindle power : 17 [kW] Tool changer magazin number of stations : 80 Max. tool length : 300 [mm] Max. weight of single tool : 7 [Kg] Total max. weight in tool changer magazin : 400 [Kg] Total power required : 57 [kVA] Supply voltage : 400 [V] Number of hours under power : 17840 [h] Weight : 15000 Kg

Request for a quote

GRAVOTECH

France

For over 30 years, TYPE EDIT has been the complete CAD/CAM software solution. Taking your ideas and drawings, through design and machining to production. - WITH 400+ POWERFUL FEATURES within 3 interactive modules, TYPE EDIT is packed with vector creation and manipulation tools, combined with 3D bas-relief, connected to a powerful CAM engine creating the smartest toolpath strategies. - COMPATIBLE WITH Unicode, 64 bit, and available in 20+ languages. TYPE EDIT is used across many sectors and applications. - APPLICABLE Engrave, Mark, Cut, Carve in 2D, 2.5D, and 3D within hard metals or soft materials, on any CNC milling machine.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

INOVER SARL

France

Standard carbide square end mills( 1, 2, 3, 4, 6 dents, HRC45-65) Carbide Ball End Mills(2 Dents) Carbide End Mills for Aluminium Carbide End Mills Long Series

Request for a quoteResults for

Mills - Import exportNumber of results

7 ProductsCountries

Company type